- 87 -

Process natural tollerance

NOTE: The Cp index is calculated only if control charts are provided for the

characteristic.

CpK

This represents the process critical capacity. It is the reference index when the

statistical aim of the batch has been indicated as Process. It is calculated using

different methods, depending on the characteristic type:

Bilateral characteristic:

Cpk = Minimum value between:

(2 * (UTL – X)) / (6*σ)

(2 * (X – LTL)) / (6*σ)

where

UTL = Upper Tolerance Limit

LTL = Lower Tolerance Limit

X = mean measurement value

σ = estimated deviation of the measurements

^

^

^

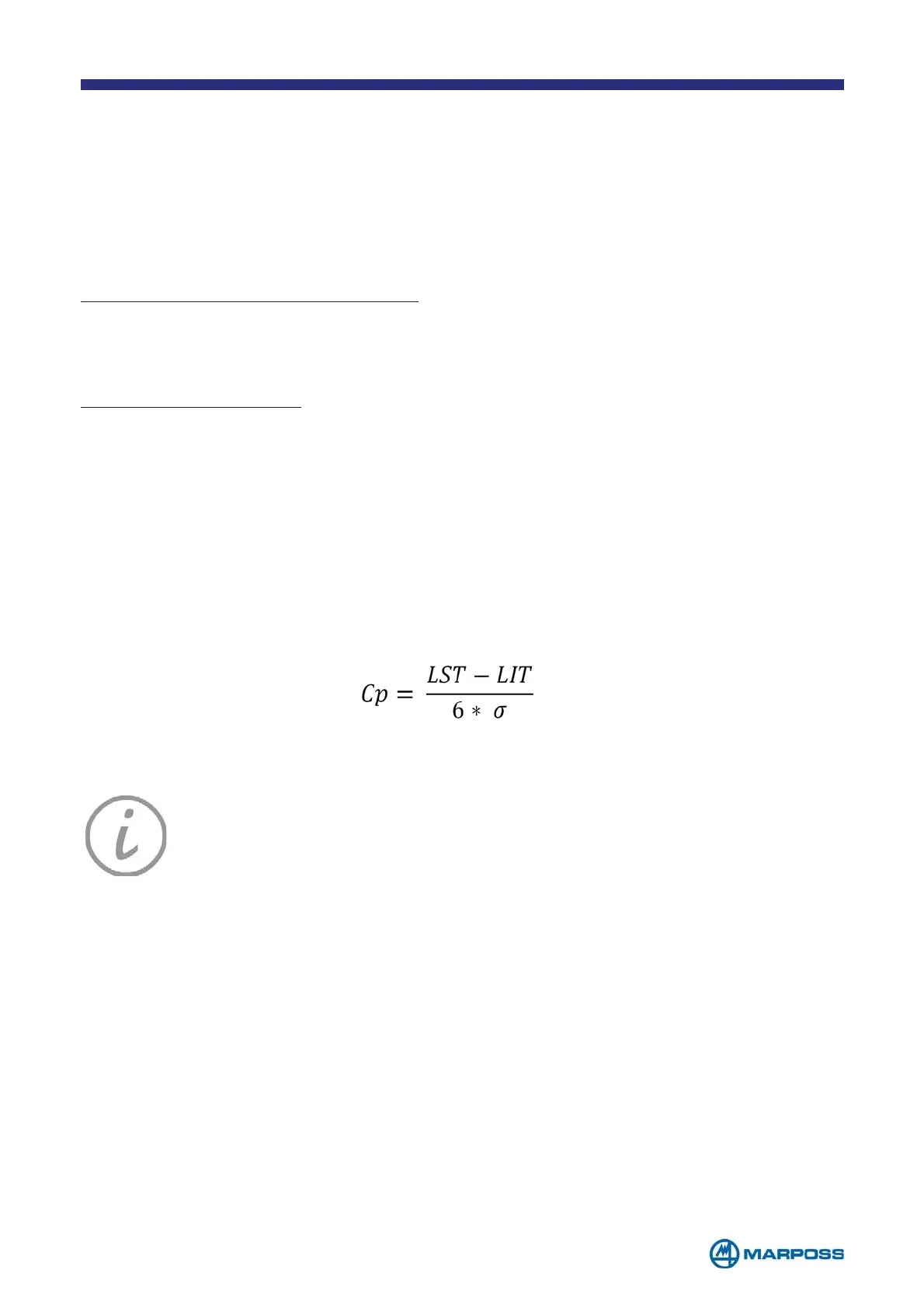

Capability indices (Cp)

The process capacity is used as the reference index when Process is selected as the

statistical scope of the batch. It is only calculated in the case of bilateral characte-

ristics, using the following formula:

Where

LST – LIT = Tolerance interval

6*σ = Process natural tolerance

^

Natural Tolerance is an attempt to express the variability inherent in a given pro-

cess. The formula depends on how the measurements are distributed. As the aim

is to represent the variability of the process, we use the Sigma Hat, estimated

using the samples, rather than the Standard Deviation S used in the case of Natu-

ral Tolerance.

Bilateral or single limit characteristic

Process Natural Tolerance = 6 * σ

Where σ is the estimated process sigma

Unilateral characteristic

with upper limit: Process Natural Tolerance=Maximum between (6*σ) and (3*σ

+X)

with lower limit: Process Natural Tolerance=Minimum between (6*σ) and (3*σ-X)

Where: σ is the standard deviation of the measurements

X is the mean value of the measurements.

^

^

^

^

^^

^

^

Loading...

Loading...