93 of 271

The right side of the adapter should be lined up with outside edge of the motor mounting

bracket.

8. Push down on the force gauge until the top of the belt lines up with the mark on the mounting

bracket. The force should be 6.8 ± 0.3 lbs.

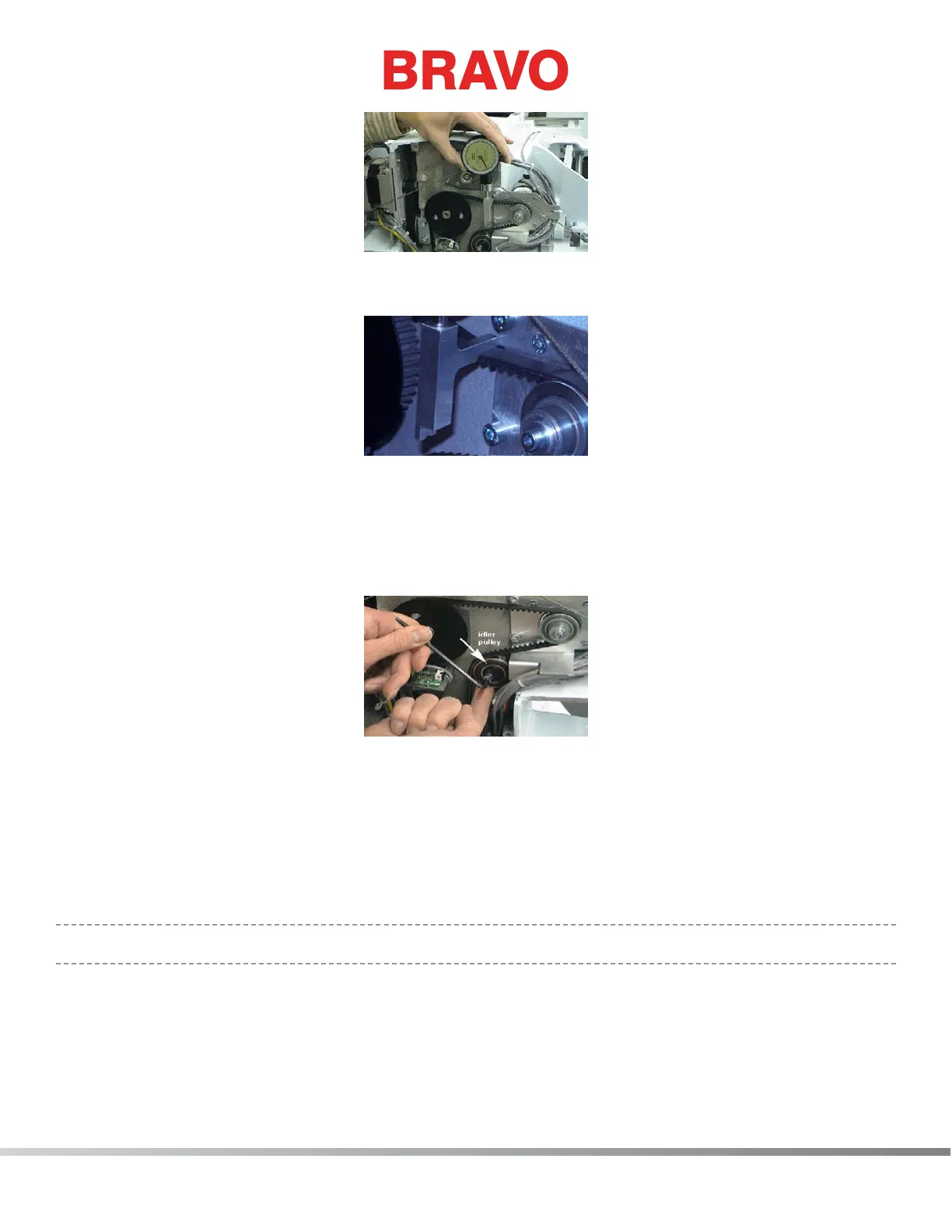

9. To adjust the tension of the z-drive belt, hold the idler pulley steady with one hand and loosen the

screw with a 3mm hex wrench. Turn the z-idler pulley clockwise to increase the tension (counter-

clockwise to reduce tension) and then tighten the screw to the Torque Specications.

Measure the tension again (as specied in Steps 7 and 8) and if it is not correct, repeat step 9 until

the tension is set to the specication.

10. Reinstall the covers in the reverse order that you removed them. Tighten the screws to The torque

specications.

11. Do a short machine functional test to verify proper z-axis timing (needle bars synchronized, with

rotary hook movement).

•

Note: If a BRECO meter is used to measure the tension, the measurement should be 72-78 Hz.

Loading...

Loading...