34 of 271

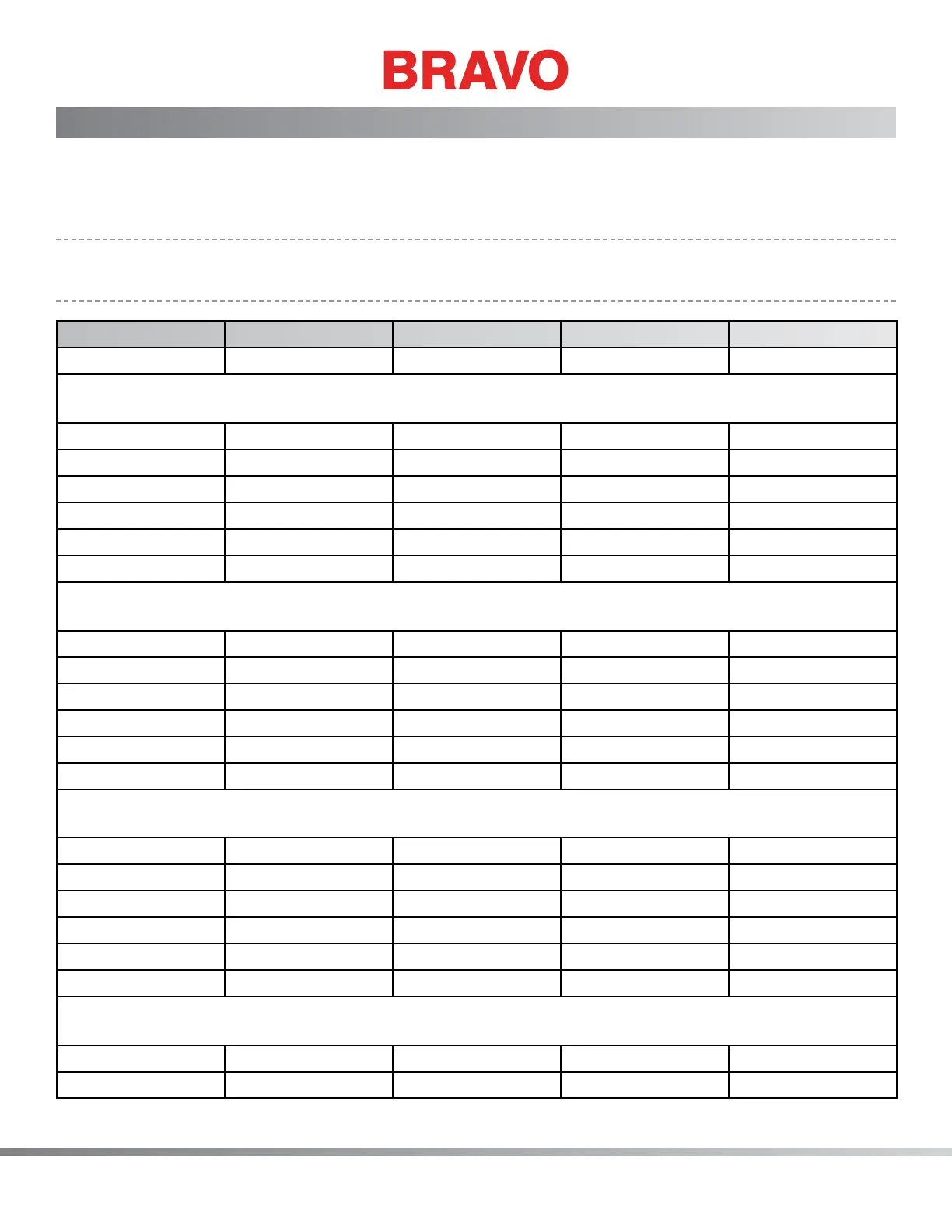

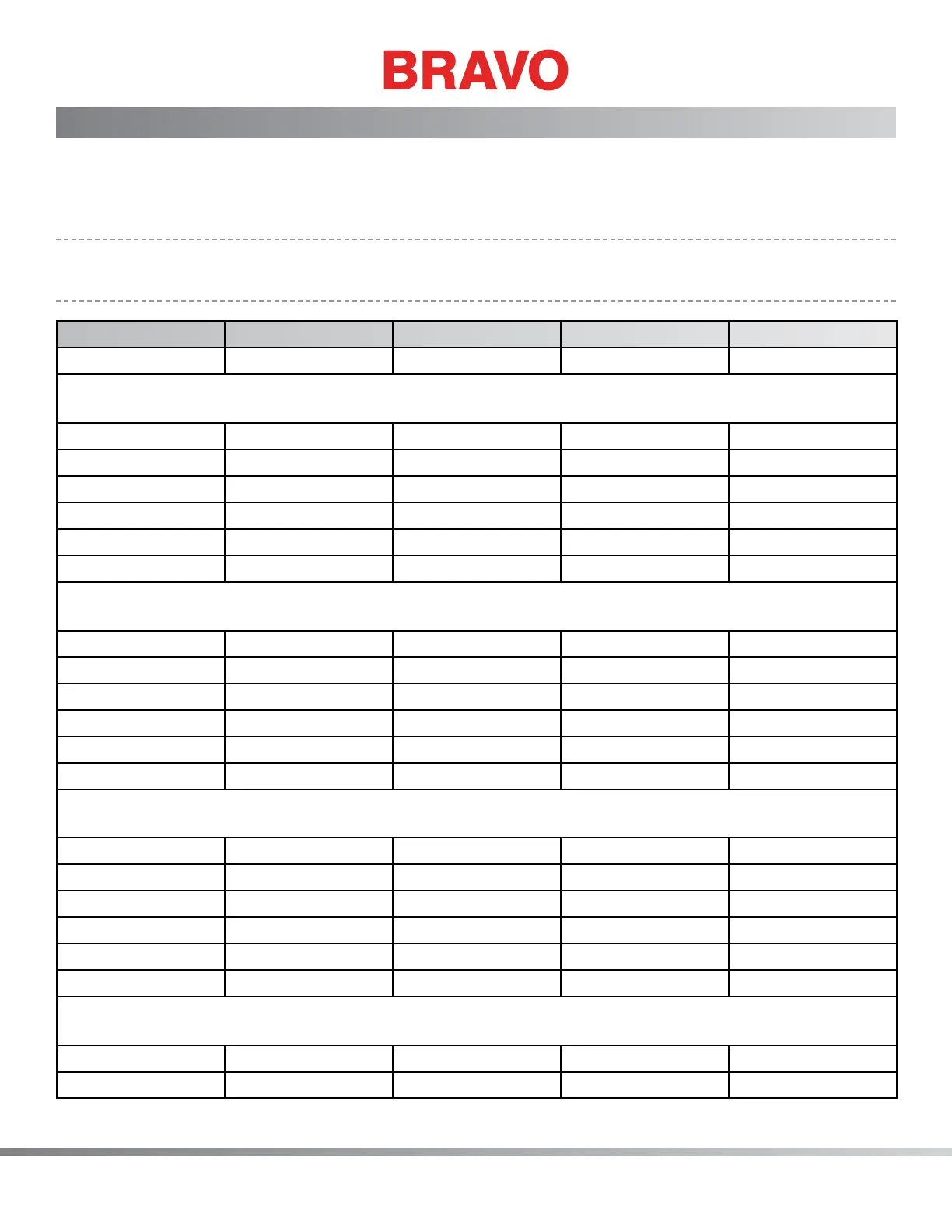

Torque Specications

The following chart depicts the torque specications for all screws and nuts used in the machine. They

should be followed unless indicated otherwise in this manual (i.e., screws going into plastic materials

require lower torque).

•

Note: Reduce torque specications when attaching optical sensors by 10% to prevent damage

to the sensor housing. Use minimum torque when screwing into or clamping plastic surfaces.

Size Min Max Min Max

In-lb In-lb N-m N-m

Zn Plated, Property Class 8.8, Socket Head Screws (PN: 010170-XX, 010171-XX, 010172-XX, 010174-

XX, 010175-XX)

M2.5 5 7 0.66 0.80

M3 10 13 1.2 1.4

M4 23 26 2.6 3.2

M5 46 56 5.1 6.3

M6 79 96 8.9 10.9

M8 190 234 21.6 26.4

Zn Plated, Property Class 4.5, Slotted and Phillips Machine Screws (PN: 006558-XX, 004262-XX,

009862-XX, 009863-XX)

M2.5 1 2 0.19 0.23

M3 3 4 0.40 0.48

M4 8 10 0.92 1.12

M5 16 19 1.8 2.2

M6 27 33 3.1 3.7

M8 45 55 5.1 6.3

Black Oxide, Property Class 12.9, Black Socket Head Screws (PN: 01922-XX, 67018-XX, 671852-XX,

671686-XX, 671687-XX, 003183-XX)

M2.5 10 12 1.2 1.4

M3 18 22 2.1 2.5

M4 43 51 4.7 5.8

M5 83 100 9.4 11.4

M6 144 175 16.2 19.8

M8 345 418 38.7 47.3

Set Screws, Property Class 45H (PN: 10188, 01962-XX, 005034-XX, 001960-XX, 10635-XX,

001971-XX)

M3 4 5 0.45 0.55

M4 8 10 0.90 1.10

Loading...

Loading...