244 of 271

Mechanical Failures

False Thread Breaks

False thread breaks on the machine are usually caused when the upper tension is too loose, such that the

thread sensor fails to detect the thread moving against the thread sensor bar.

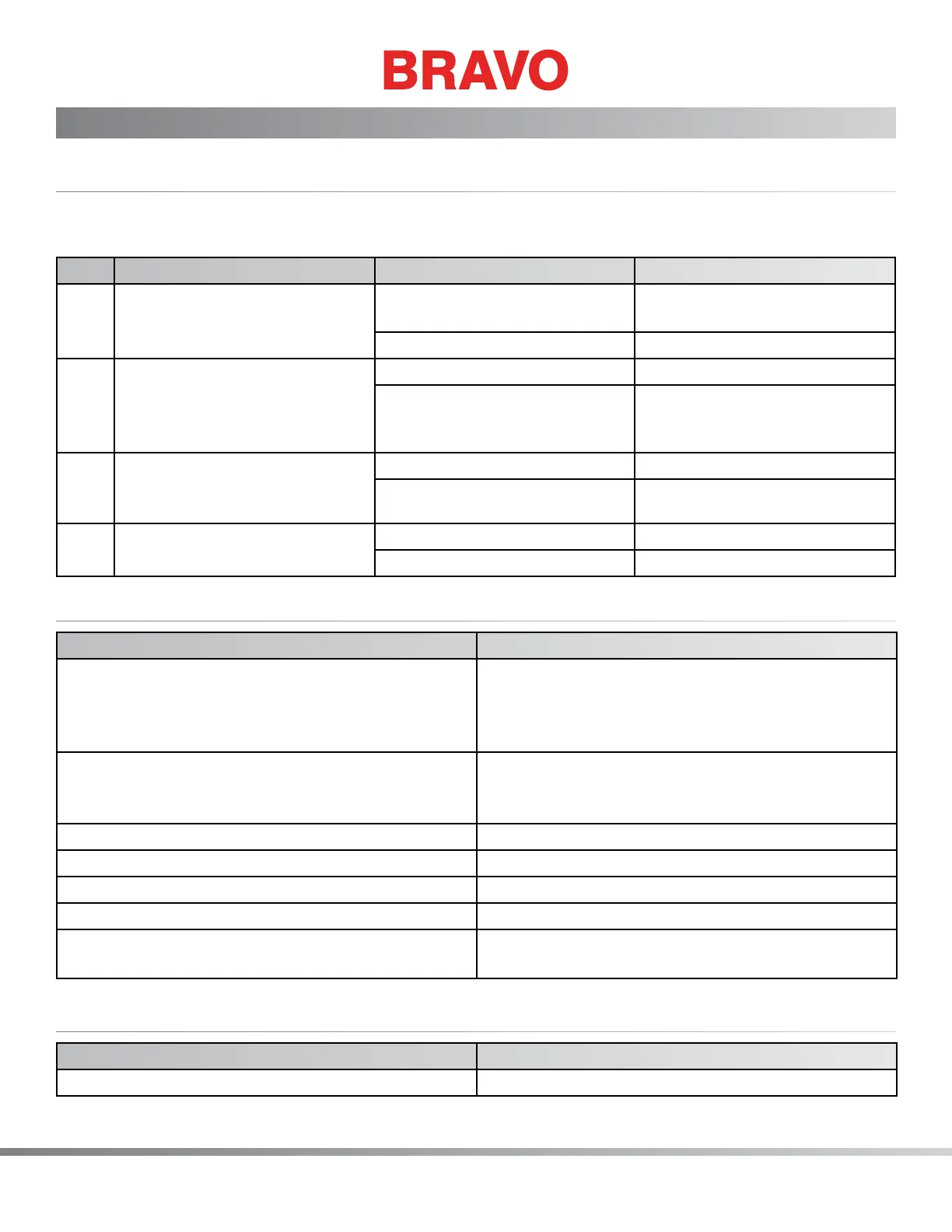

Step Symptom/Procedure Condition Solution/Step

1 Check upper thread tension Too loose Adjust thread feed parameters

in the software

Correct Tension Go to Step 2

2 Tighten the thread feed pa-

rameters (reduce the amount

of thread feed in and see if

problem goes away)

Problem goes away Tension was too loose

Problem still occurs Go to Step 3

3 Inspect condition of thread

feeder rollers. They may be

damaged or worn.

Damaged or worn Replace rollers

Rollers all good Go to Step 4

4 Replace thread break sensor

assembly

Problem goes away Sensor is bad

Problem still occurs Contact Technical Support

Loose/Looping Stitches

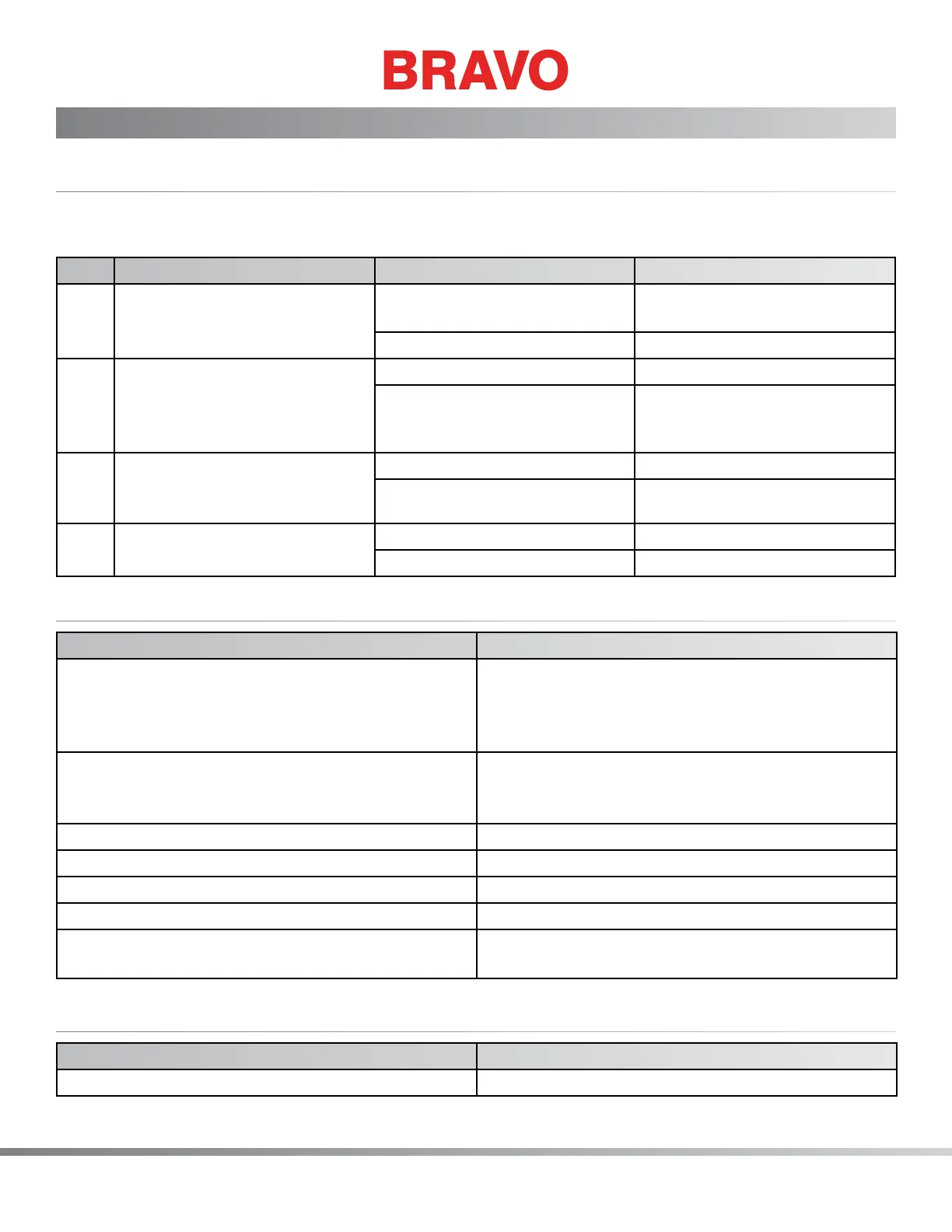

Possible Causes Solutions

Thread feed settings too low Troubleshoot the thread feeder assembly. Check

the adjustment of the tread feed parameters in the

Bravo OS software. Contact Technical Support if

necessary.

Bobbin tension too low Adjust the bobbin tension by tightening the screw

on the bobbin case. Refer to the Operator Manual

for instructions.

Uneven thread size Replace with quality thread

Rotary hook timing is incorrect Adjust hook timing

Inadequate rotary hook lubrication Lubricate the rotary hook

Thread feeder roller worn or damaged Replace thread feeder roller

Design density too tight Decrease density (refer to Bravo OS manual for

design editing)

Needle Breaks

Possible Causes Solution

Needle is bent Replace needle

Loading...

Loading...