POWER TRAIN

-

Automatic Transaxle

2-55

Torque converter

control valve

Overdrive clutch

Solenoid

Pump (IN)

1

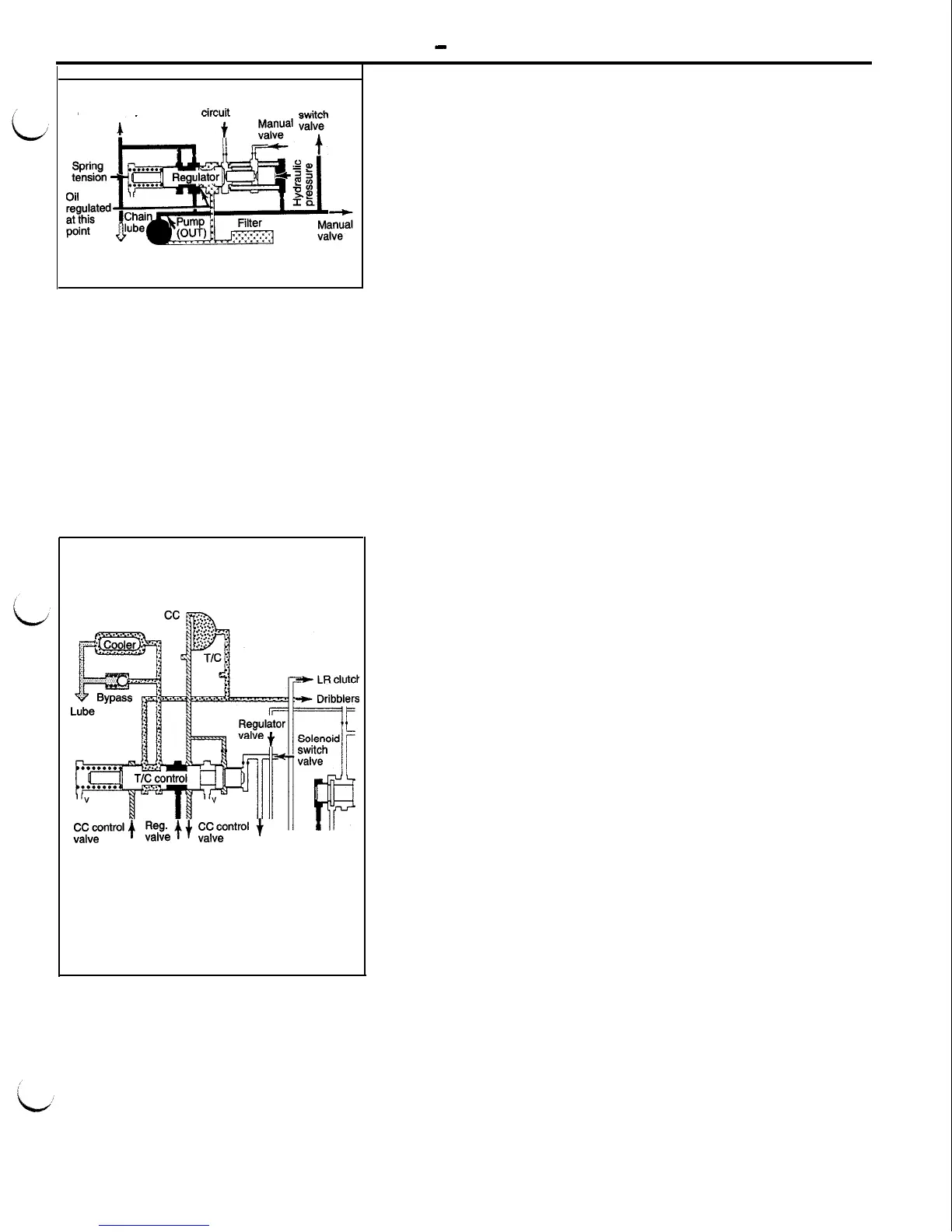

Regulator Valve

The regulator valve has one function, to regulate or control

hydraulic pressure in the transaxle. The pump supplies unregu-

lated pressure to the regulator valve. The regulator valve con-

trols or limits pump pressure. Regulated pressure is referred

to as “line pressure”. The regulator valve has a spring on one

end that pushes the valve to the right. This closes a dump

(vent) to lower pressure. Closing the dump will cause oil pres-

sure to increase. Oil pressure on the opposite end of the valve

pushes the valve to the left, opening the dump and lowering

oil pressure. The result is spring tension working against oil

pressure to keep or maintain the oil at specific pressures. Regu-

lated pressure will vary depending on the gear range the trans-

axle is operating in.

A system of sleeves and ports allows the regulator valve to

work at one of three different predetermined pressure levels.

The oil that is dumped by the regulator valve is directed back

to the intake side of the oil pump.

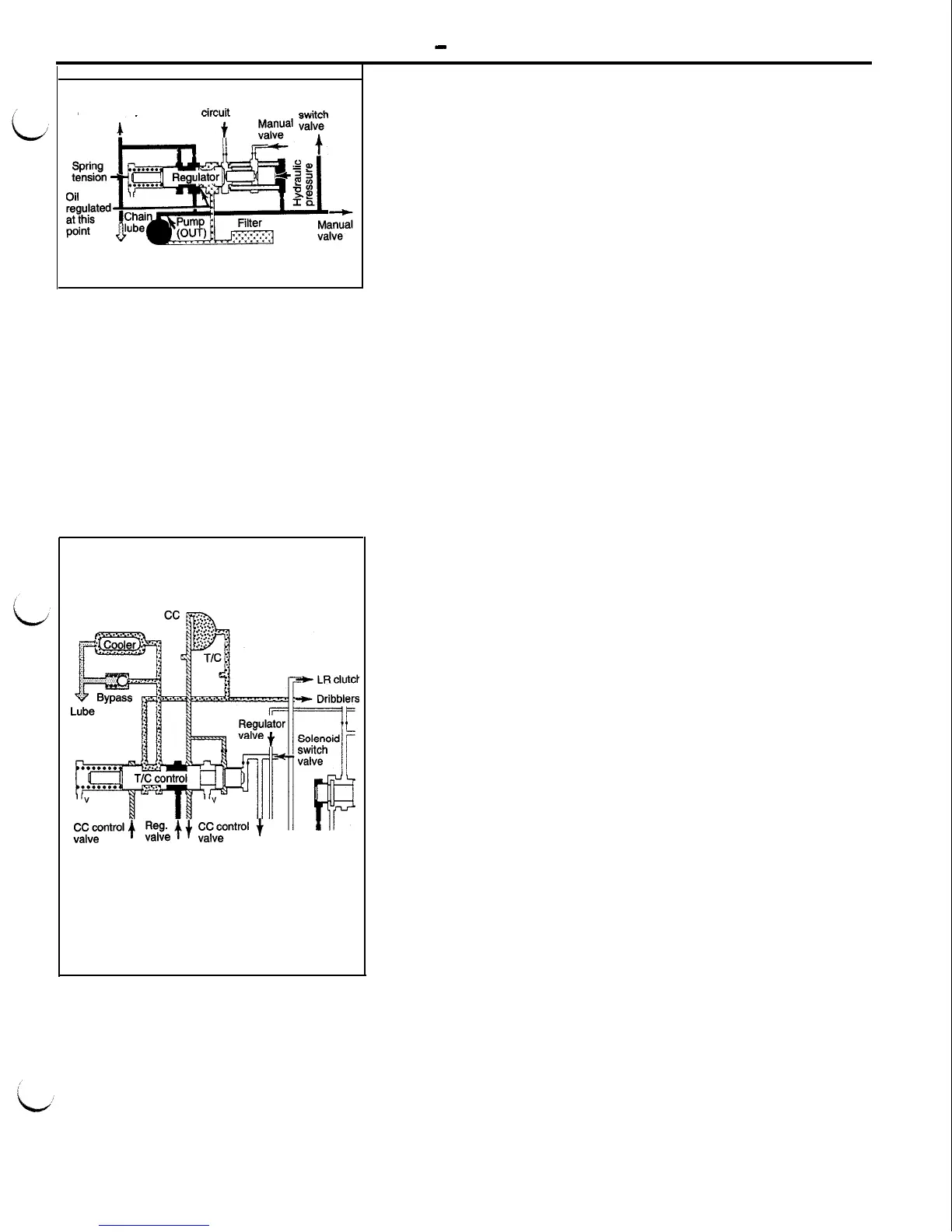

Torque Converter Control Valve

The main responsibility of the torque converter (T/C) control

valve is to control hydraulic pressure applied to the front (“off”)

side of the converter clutch (CC). Line pressure from the regula-

tor valve is fed to the T/C control valve where it passes through

the valve. The T/C control valve reduces or regulates the pres-

sure slightly. The T/C control valve pressure is then directed

to the converter clutch (CC) control valve and to the front

side of the converter clutch piston.

The pressure that is being fed to the front of the piston pushes

the piston back. This disengages the converter clutch. The

oil then passes around the outside of the piston, flowing out

of the torque converter and back to the T/C control valve.

From the T/C control valve the oil flows to the transaxle oil

cooler and cooler bypass valve. It returns to the transaxle

as lube oil pressure.

Loading...

Loading...