2-94

POWER TRAIN

-

Automatic Transaxle

Solenoid Switch Valve Control Logic

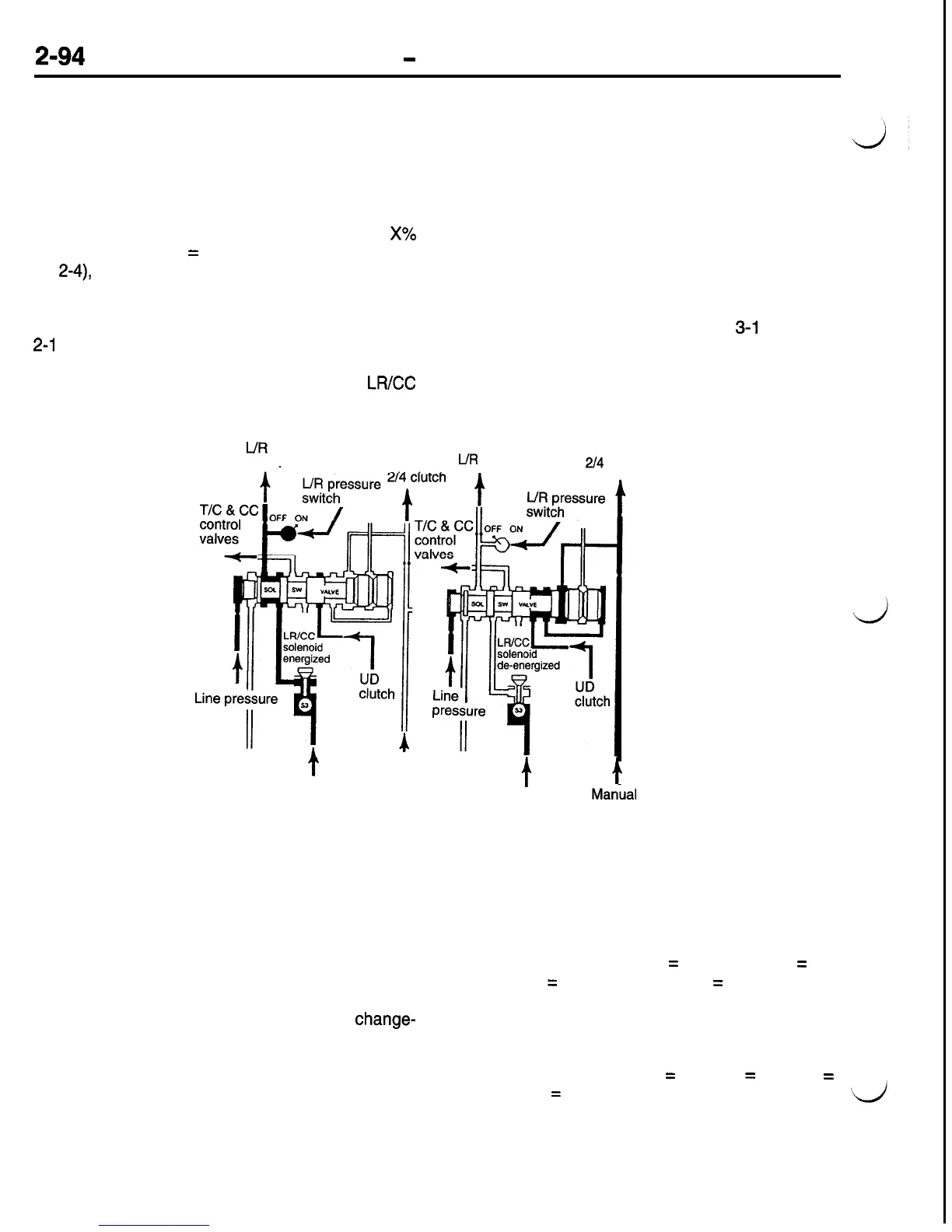

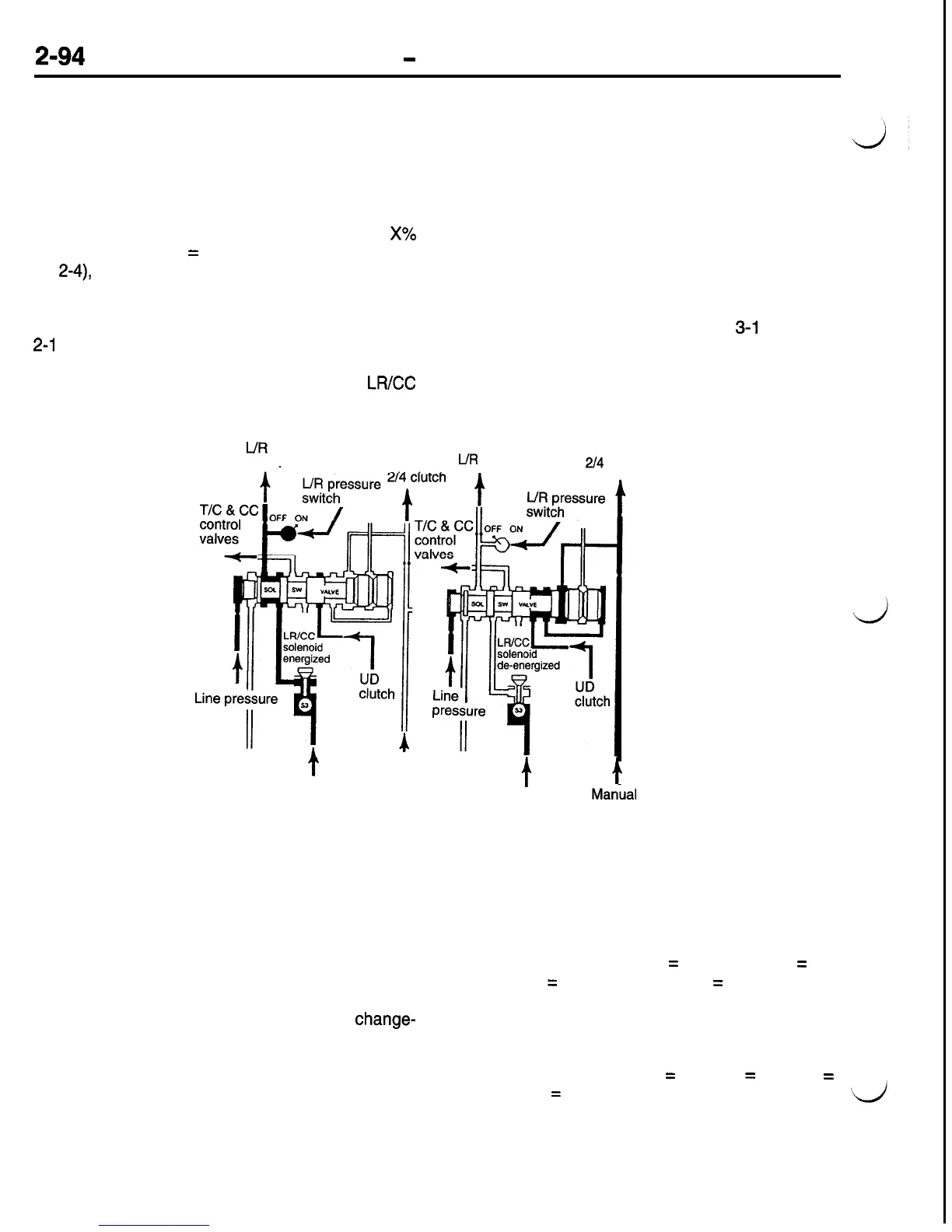

This valve protects against the inadvertent applica-

tion of LR clutch in second, third, or fourth gear

ranges. When shifting to first gear, the Solenoid

Switch Valve (SSV) must be in the downshifted posi-

tion or action must be taken to shift the SSV into

the downshifted position. As long as any of three

pressures (2-4, OD, or UD) are greater than

X%

of line pressure (X

=

60% for UD and OD, 70%

for

2-4),

the SSV will remain upshifted. To confirm

that the SSV has downshifted, both the LR solenoid

and LR pressure switch must be high (voltage value

seen by TCM). To downshift the valve for 3-1 or

2-1

shifts, shift logic will briefly vent the UD clutch

(shift logic must vent the other two clutches also)

and test for valve motion by eneraizing the

LR/CC

L/R

clutch

solenoid and verifying that the LR pressure switch

turns on.

A SSV diagnostic trouble code will only be stored

if the transaxle operating temperature range is hot,

and the malfunction occurs at least three times.

The fault counter is reset during the start routine.

Under certain conditions, such as very cold fluid

temperatures, it is possible that the SSV valve may

not move as quickly as it normally would at operating

temperature. This slow response may occasionally

result in a second gear launch or a change mind

shift to second gear from a 2-l or

3-1

shift. No

diagnostic trouble code will be set if the transaxle

operating temperature range is cold.

UR

clutch

2/4

clutch

I

Manual

Manual

valve

valve

Clutch Apply Status

To execute the shift logic, the TCM must maintain

a continuous record of each clutch element apply

status. This is done by tracking the instantaneous

fluid volumes in each clutch circuit. Instantaneous

fluid volumes are tracked using predetermined flow

rates and learned “clutch fill volumes”. This is partic-

ularly useful for closely-spaced shifts or

change-

mind shifts.

Learned clutch fill volumes represent the volume

of fluid that is required to stroke a clutch piston

to the point where zero clutch pack clearance is

obtained. The clutch fill volume learn value is the

fill volume

without stroking the accumulator or pick-

ing up any torque load on the clutch. This learned

fill volume is updated for each clutch element as

it wears and clutch pack clearance increases.

Manual

valve

Manual

valve

The Clutch Volume Index (CVI) display of the scan

tool (MUT-II) can be used to view learned clutch

fill volumes for each clutch. The normal range for

clutch fill volumes are LR

=

35 to 85, OD

=

75

to 150, 2-4

=

20 to 77, and UD

=

24 to 70.

If the battery feed is disconnected from the TCM,

the learned clutch fill volumes will be lost, and initial

values will be substituted until correct values can

be re-learned. Shifting may be somewhat harsh.

The initial values are; LR

=

64, OD

=

89, 2-4

=

48, and UD

=

45.

A transmission which has experienced a sudden

clutch failure may not be capable of learning the

correct values. A road test of a transaxle with this

condition may exhibit an upshift runaway condition,

but have acceptable clutch fill volumes.

Loading...

Loading...