POWER TRAIN

-

Automatic Transaxle

TRANSMISSION CONTROL MODULE INPUTS AND SENSORS

L

The TCM must depend on receiving information

’

in order to control shift quality. Let’s take a look

Direct Battery Voltage

There is constant battery voltage supplied to the

TCM, even when the ignition is turned off. This

battery supply is responsible for keeping the

TCM’s

memory alive. If the TCM loses battery voltage at

Ignition Voltage

When the ignition switch is turned to the OFF (col-

umn unlock), the RUN (on), or the Start (crank)

positions, the TCM is activated and looks at incoming

voltage. If the voltage is above approximately 24

volts or below eight volts, the TCM automatically

puts itself in default. Either voltage condition could

damage the TCM.

When the TCM is activated, besides checking the

incoming voltage level, it performs a self-test to

determine if the transmission control relay and the

solenoid assembly are performing as they should.

at what information it receives and how it uses that

information.

any time, it will lose the adaptive memory and have

to re-learn the characteristics of the transaxle for

optimum shift quality.

If the self-test results are good, the TCM sends

battery voltage to the transmission control relay.

The relay closes its internal contacts which supply

battery voltage to the TCM, the four solenoids and

the three pressure switches in the solenoid assem-

bly. Whenever the TCM goes into default, it de-ener-

gize the transmission control relay and prevents

the solenoids from functioning. The solenoids will

then be in de-energized positions, which cause the

transaxle to shift into second gear.

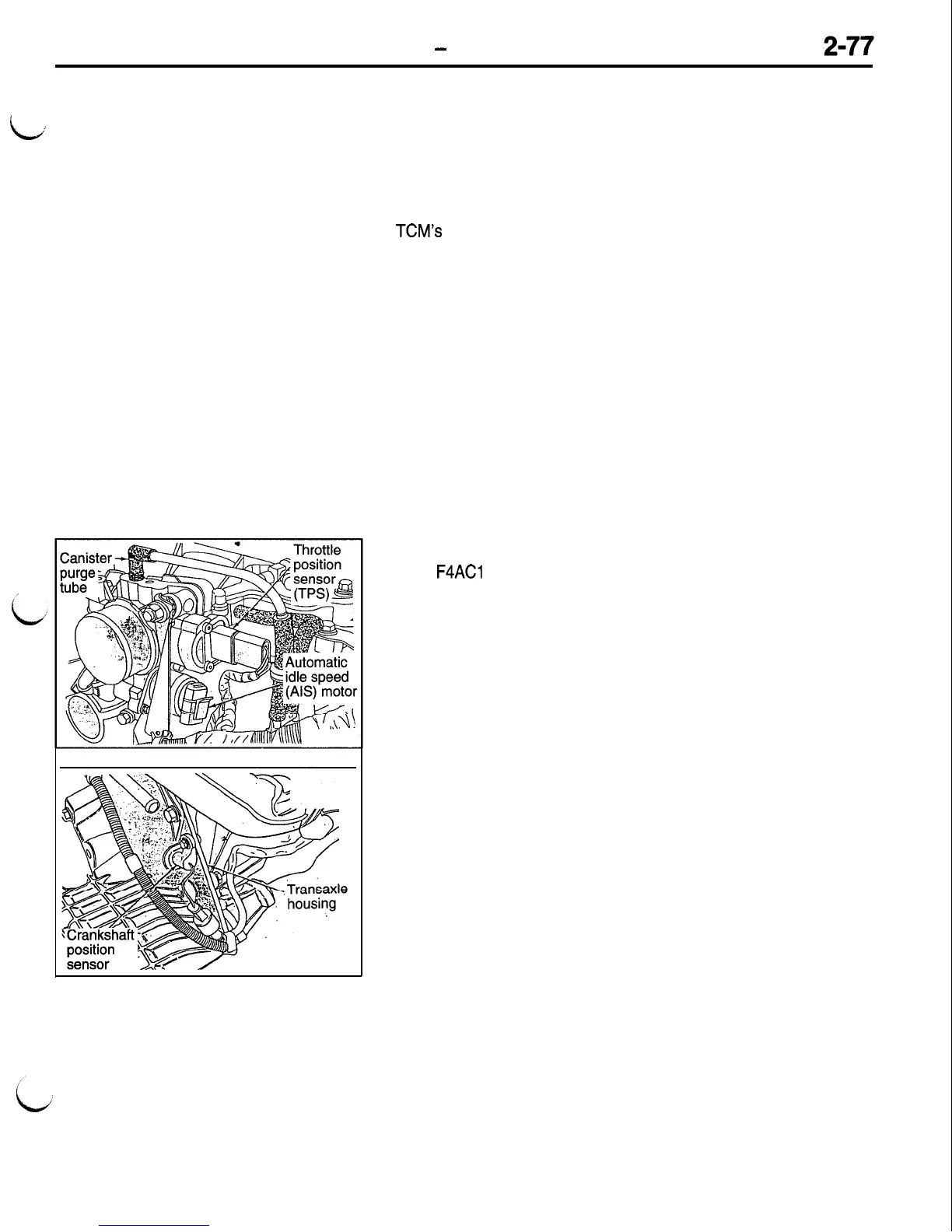

Throttle Position Sensor

The

F4ACl

does not use throttle pressure to control shift points

like previous transaxles did. Instead, an electronic signal from

the Throttle Position Sensor is used by the TCM to help deter-

mine shift points and shift quality.

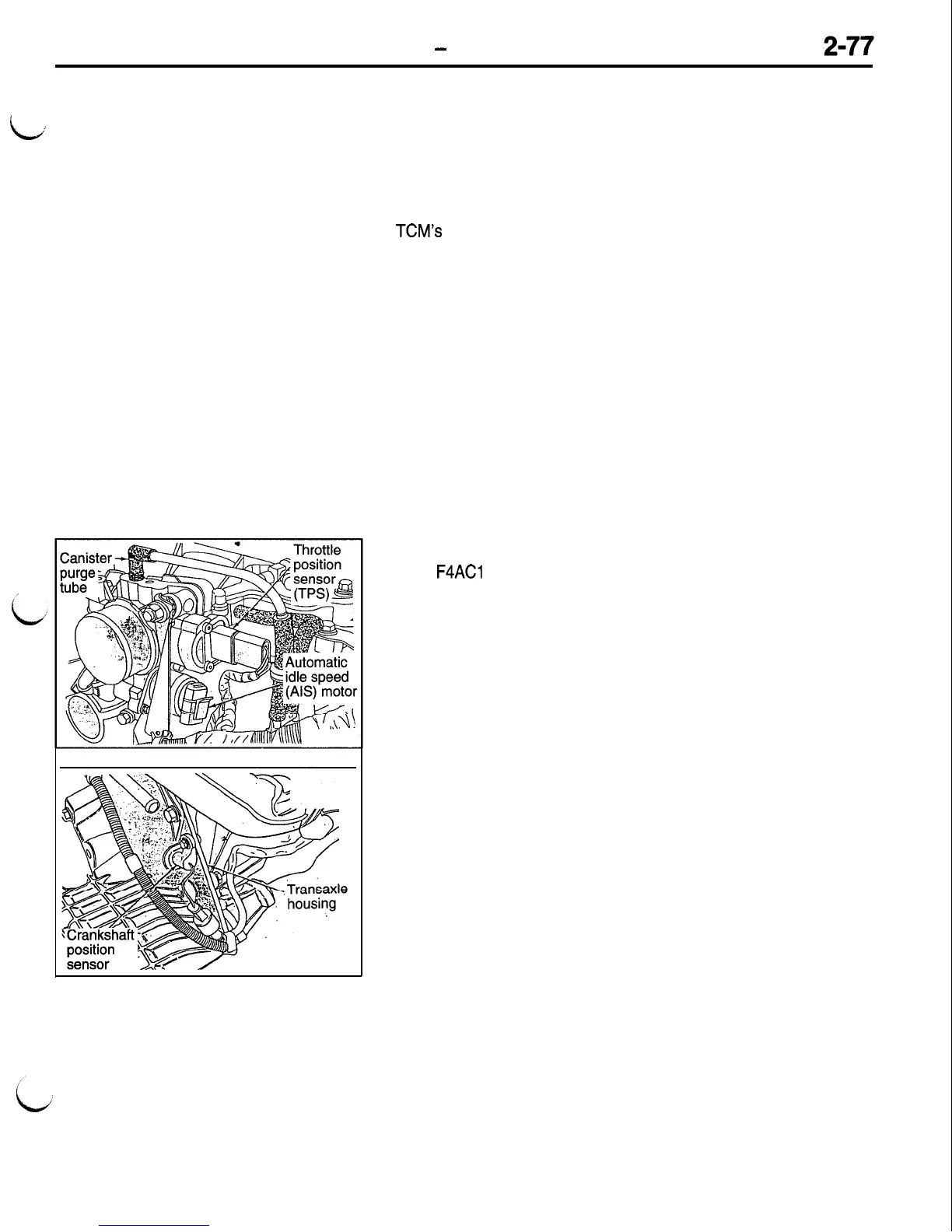

Engine Speed Signal

Engine speed is supplied to the TCM from the engine crankshaft

position sensor or distributor, depending on the engine and

ignition system used. This signal not only lets the TCM know

the engine is running, but also lets the TCM calculate engine

speed to control torque converter clutch engagement, deter-

mine torque capacity, etc.

Loading...

Loading...