ENGINE

<NON-TURBO>

-

Control System

I-43

Operation

ii

The Power-train Control Module (PCM) varies the

pulse width of the fuel injectors to provide precise

control of the air/fuel mixture. Wider pulse widths

increase the volume of fuel delivered to the cylinders.

The PCM uses the input from a number of sensors

in its attempt to reach and maintain this air/fuel

ratio. Manifold Absolute Pressure (MAP), and the

02

sensor have the greatest influence (authority)

over injector pulse width. Other inputs such as the

Throttle Position Sensor (TPS), engine RPM, Engine

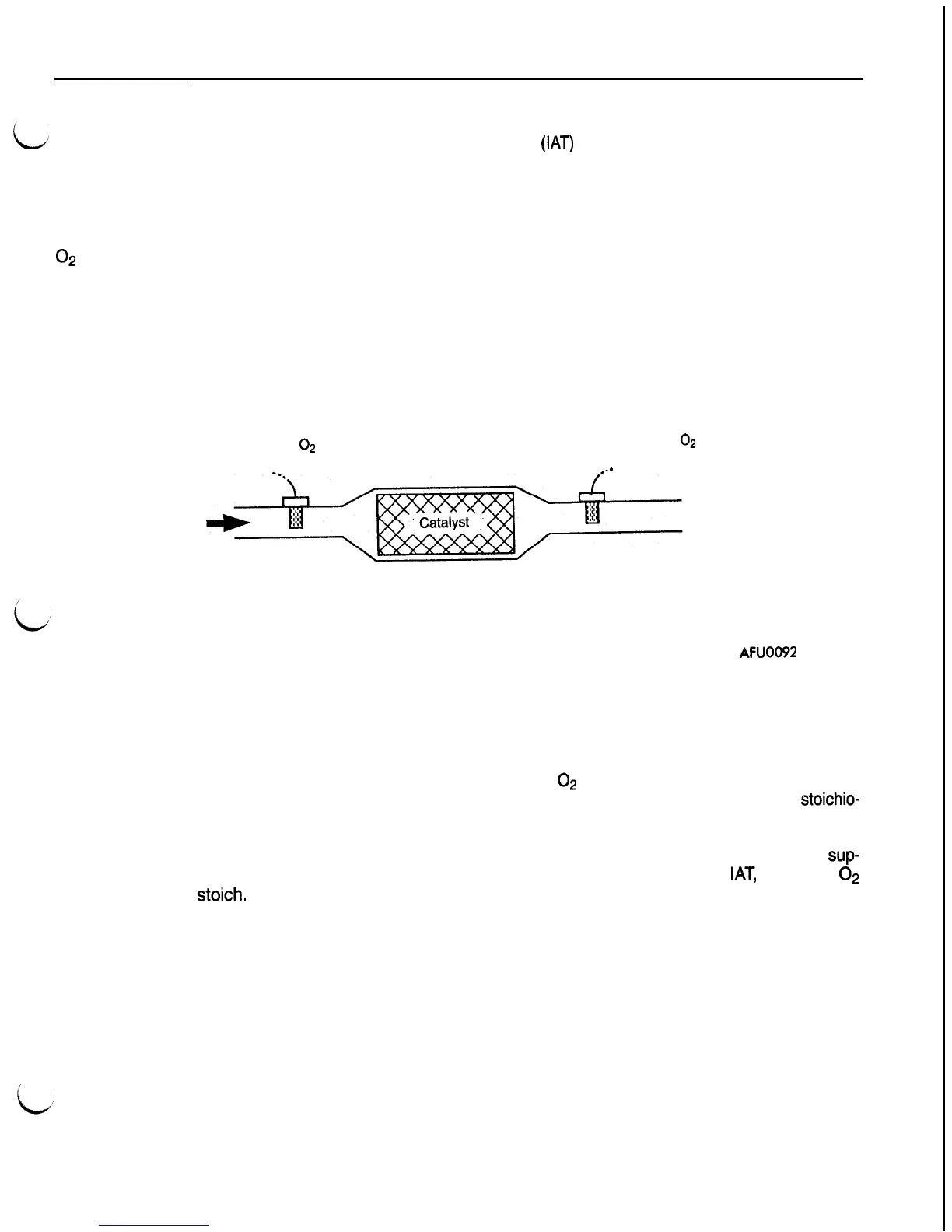

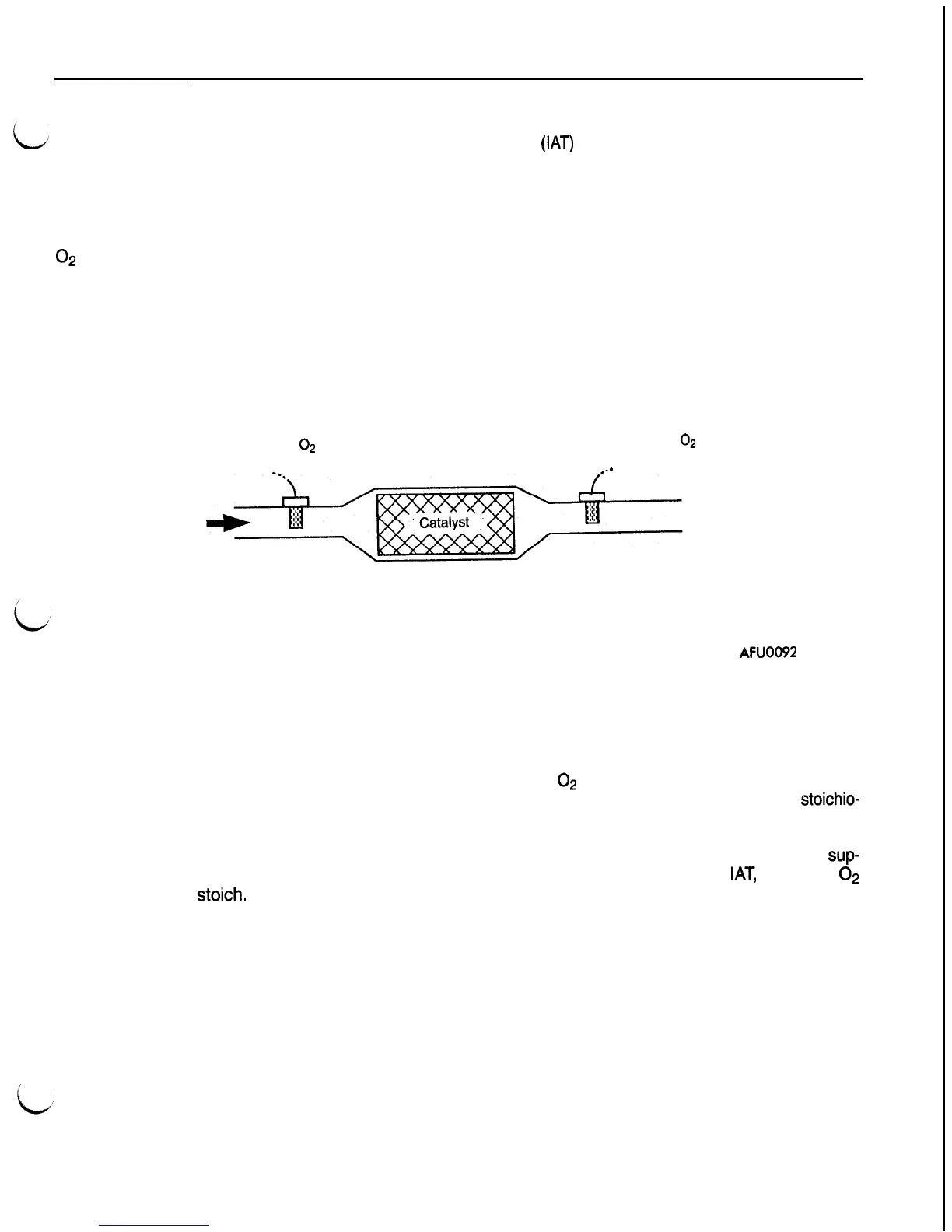

Upstream

02

sensor

Coolant Temperature (ECT) Sensor, Intake Air Tem-

perature

(IAT)

Sensor. Vehicle Speed Sensor (VSS)

and battery voltage all have varying levels of influ-

ence on pulse width, depending on the circum-

stances.

As noted earlier, the system uses two oxygen sen-

sors both of which monitor the oxygen content of

the combustion byproducts on their way out of the

engine as exhaust. Only the upstream sensor has

authority over fuel injector pulse width.

Downstream

02

sensor

_.

Exhaust gas

AFU0092

If a large amount of oxygen remains following the

combustion process, this sensor produces a low

voltage. This indicates a lean condition caused by

a ratio greater than stoichiometric. Little oxygen

in the exhaust allows the sensor to produce a higher

voltage, indicating a rich condition where the air/fuel

ratio is less than

stoich.

Upstream

02

sensor feedback to the PCM is used

to fine tune injector pulse width to maintain

stoichio-

metric and meet emission standards. It can increase

or decrease injector pulse width by as much as

50%. Pulse width is calculated from the data

sup-

plied from the MAP, TPS, ECT,

IAT,

upstream

02

sensor, battery voltage, RPM and VSS.

Loading...

Loading...