8

2 Setup

No. 99MBC122A

2.2

Mounting

2.2.1 Gage Head

Contact point replacement procedure

Various optional special contact points and extender rods for the dial indicators are available.

A sharp tipped contact point may cause injury.Be extremely careful in handling when replacing and using it.

When replacing the contact point, use the supplied spanner and do not apply a strong turning or lateral force to

the spindle. Doing so may cause damage or malfunction of the spindle.

Tips

• A new contact point may change the external dimensions and measuring force, and the measuring direction

may be limited.

• Depending on the shape, use of a contact point other than those supplied may cause errors to accumulate.

1

Remove the gage head from the stand.

2

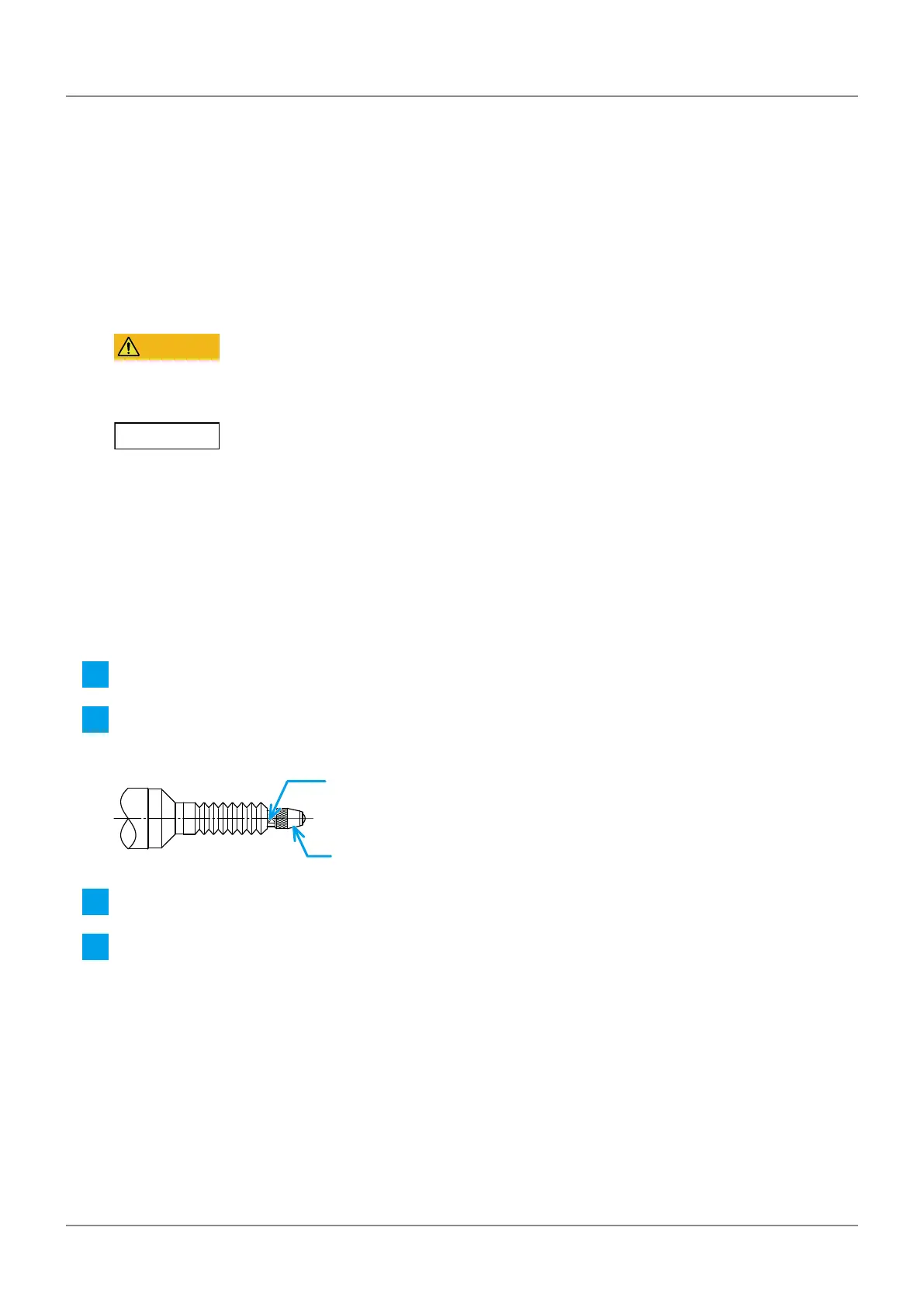

Set the supplied spanner to the spanner catch at the tip of the spindle (see the gure below) to lock the

rotation of the spindle.

Spanner catch

Contact point

3

Use pliers over a soft cloth to pinch the contact point to protect the contact point and remove it.

4

Attach the contact point in reverse order of removal.

Tips

• The recommended tightening torque is 0.5 N・m.

• After attaching the contact point, make sure that it is not loose.

• For the contact points of the dial indicator, see the General Catalog.

Loading...

Loading...