5-78

5-16 User Parameters

5

Operating Functions

• Use these parameters to set the electronic gear.

• The electronic gear can be used for the following:

• To set the amount of Servomotor rotation or movement per input command pulse.

• To increase the nominal command pulse frequency by using a multiplier when the desired

Servomotor speed cannot be achieved due to the limited pulse oscillation capability of the host

controller.

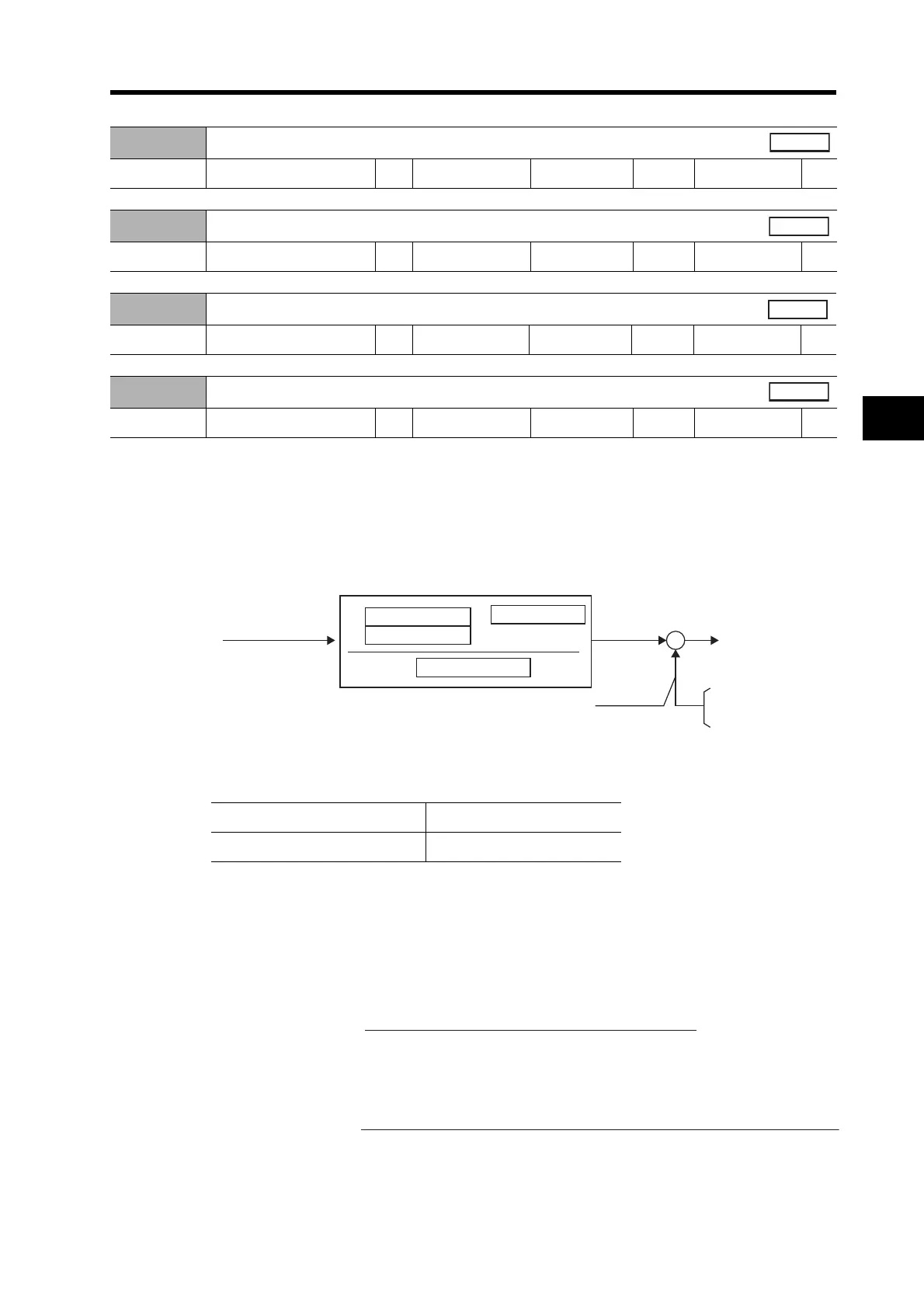

• Electronic Gear Block Diagram

*1. Numerator 1 or Numerator 2 is selected using the Electronic Gear Switch Input (GESEL: CN1 pin

28).

• The gear ratio is set using the following equations.

If the numerator equals 0, the following value is set automatically.

Numerator ((Pn48 or Pn49) × 2

Pn4A

) = Encoder resolution

In this case, the number of command pulses per revolution can be set in Pn4B.

If the numerator does not equal 0, the gear ratio is as follows:

The upper limit of the calculated numerator ((Pn48 or Pn49) × 2

Pn4A

) is 4,194,304/ (Pn4D setting

+ 1).

Pn48

Electronic Gear Ratio Numerator 1

Setting range 0 to 10000 Unit --- Default setting 0

Power OFF→ON

---

Pn49

Electronic Gear Ratio Numerator 2

Setting range 0 to 10000 Unit --- Default setting 0

Power OFF→ON

---

Pn4A

Electronic Gear Ratio Numerator Exponent

Setting range 0 to 17 Unit --- Default setting 0

Power OFF→ON

---

Pn4B

Electronic Gear Ratio Denominator

Setting range 0 to 10000 Unit --- Default setting 10000

Power OFF→ON

---

GESEL input open Numerator 1 (Pn48) selected.

GESEL input connected to COM Numerator 2 (Pn49) selected.

× 2

*1

*1

F

f

+

−

Command pulses

Numerator 1 (Pn48)

Numerator 2 (Pn49)

Exponent (Pn4A)

Denominator (Pn4B)

Internal

command

Feedback

pulses

(resolution)

To deviation

counter

10,000 pulses/re

or

2

17

ulses/rev

Electronic gear ratio =

Encoder resolution

Number of command pulses per Servomotor rotation (Pn4B)

Electronic gear ratio =

Electronic gear ratio numerator (Pn48 or Pn49) × 2

Electronic gear ratio numerator exponent (Pn4A)

Electronic gear ratio denominator (Pn4B)

Loading...

Loading...