Care and Maintenance

68

10

12

0

6

4

2

8

16

14

100

50

150

0

200

230

113-014

12.02 Cleaning

Switch off the machine and let it cool down!

Danger of burns if the heating element is touched!

● Clear the opening of the hot air nozzle from sealing residues as required.

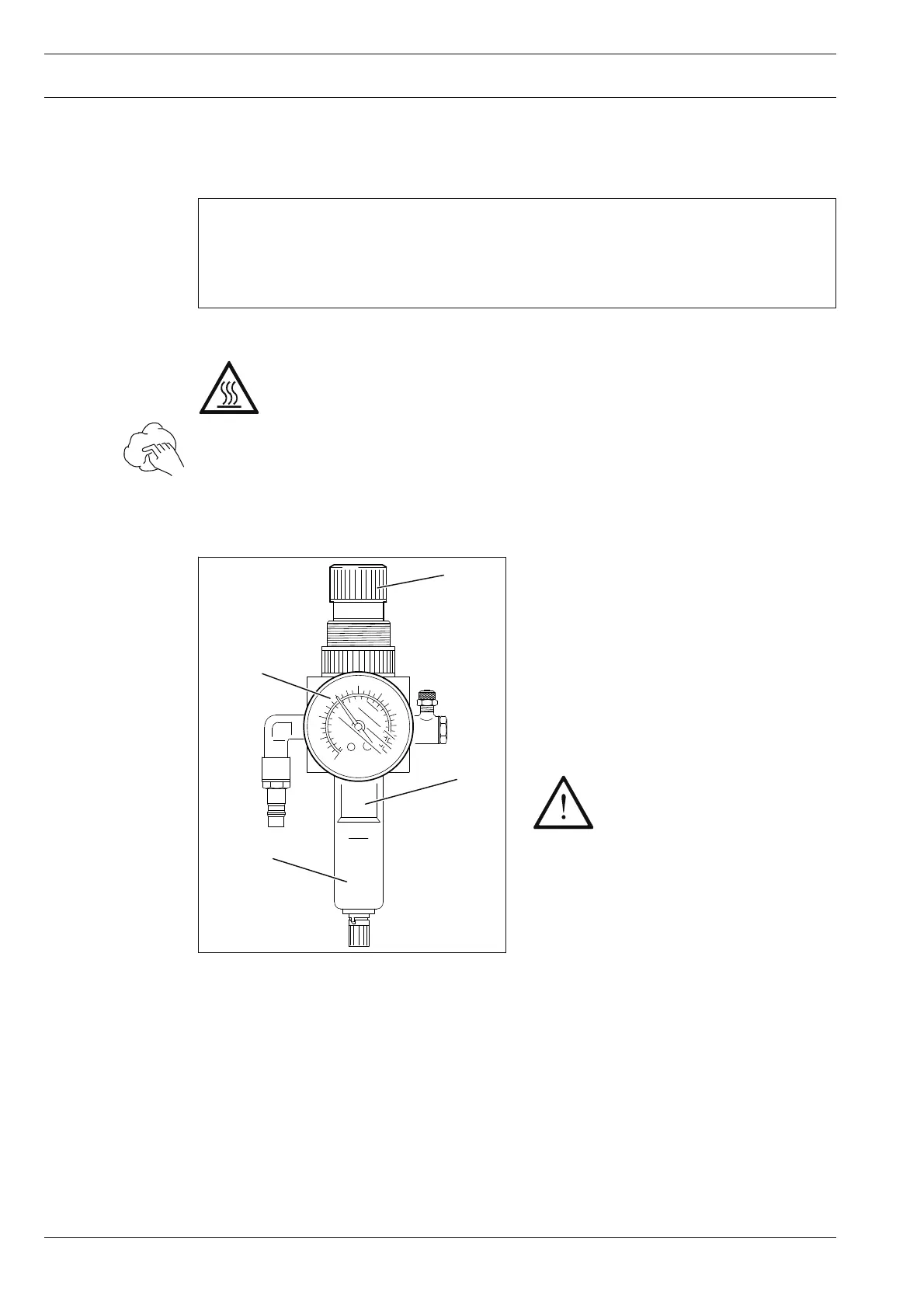

12.03 Checking the air fi lter/lubricator

Checking/adjusting the air pressure

● Before operating the machine, always

check the air pressure on gauge1.

● Gauge 1 must show a pressure of 6 bar.

● If necessary adjust to this reading.

● To do so, pull knob 2 upwards and turn

it so that the gauge shows a pressure of

6 bar.

Switch the machine off!

Disconnect the air hose at the

air-fi lter/lubricator.

To drain water bowl

● Water bowl 3 drains itself automatically

whe the compressed-air hose is discon-

nected from the air-fi lter/lubricator.

Cleaning fi lter

● Unscrew water bowl 3 and Take out

fi lter 4.

● Clean fi lter 4 with compressed air or iso-

propyl alcohol (part No. 95-665 735-91).

● Screw in fi lter 4 and screw on water

bowl 3.

Fig. 12 - 01

1

2

3

4

Cleaning the hot air nozzle .................................................................................. as required

Cleaning the air fi lter/lubricator ....................................................daily, before each start up

Changing the feed roller ...................................................................................... as required

12 Care and Maintenance

12

.01 Servicing and maintenance intervals

Loading...

Loading...