Adjustment

89

13.10.04 Parameter list

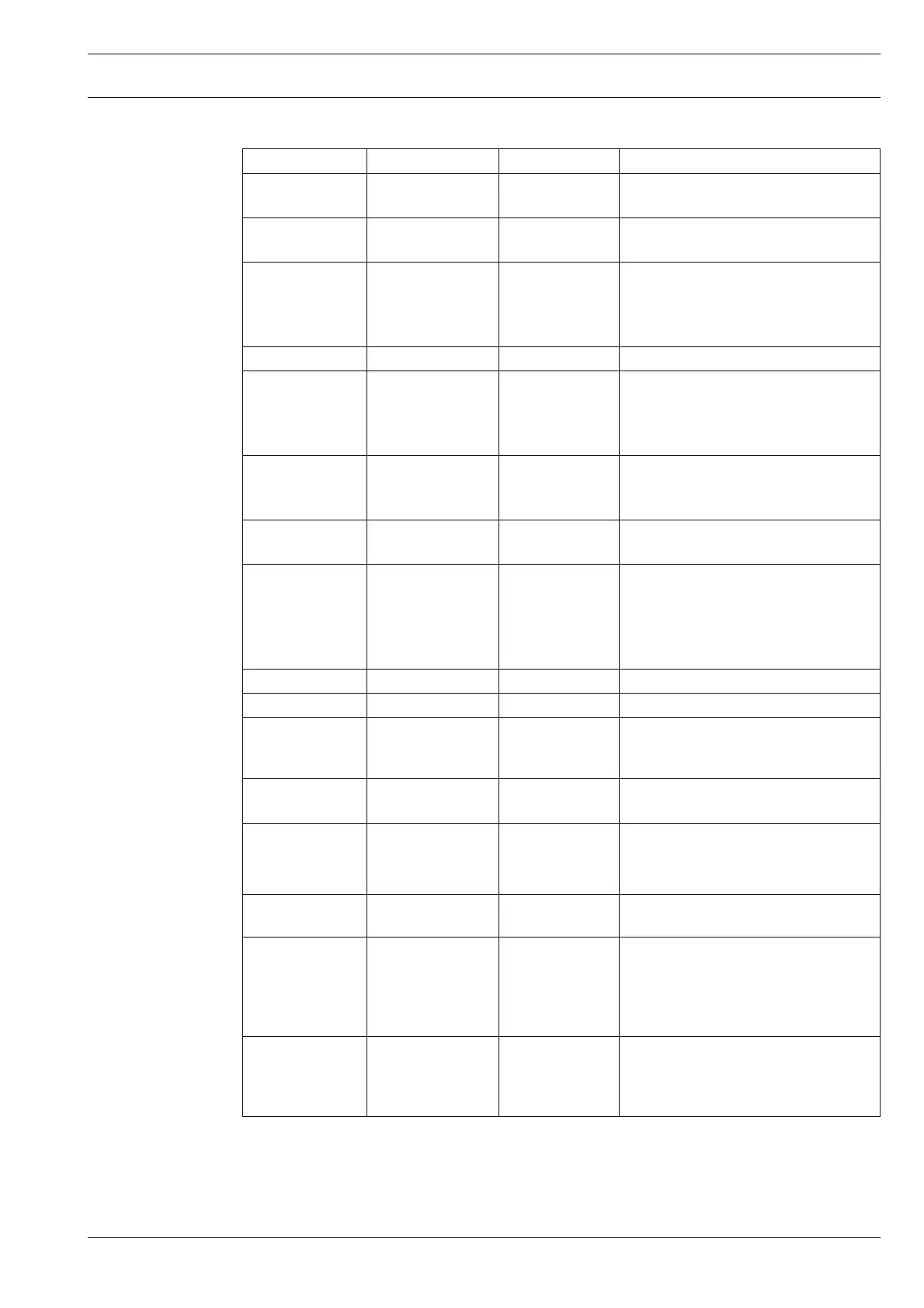

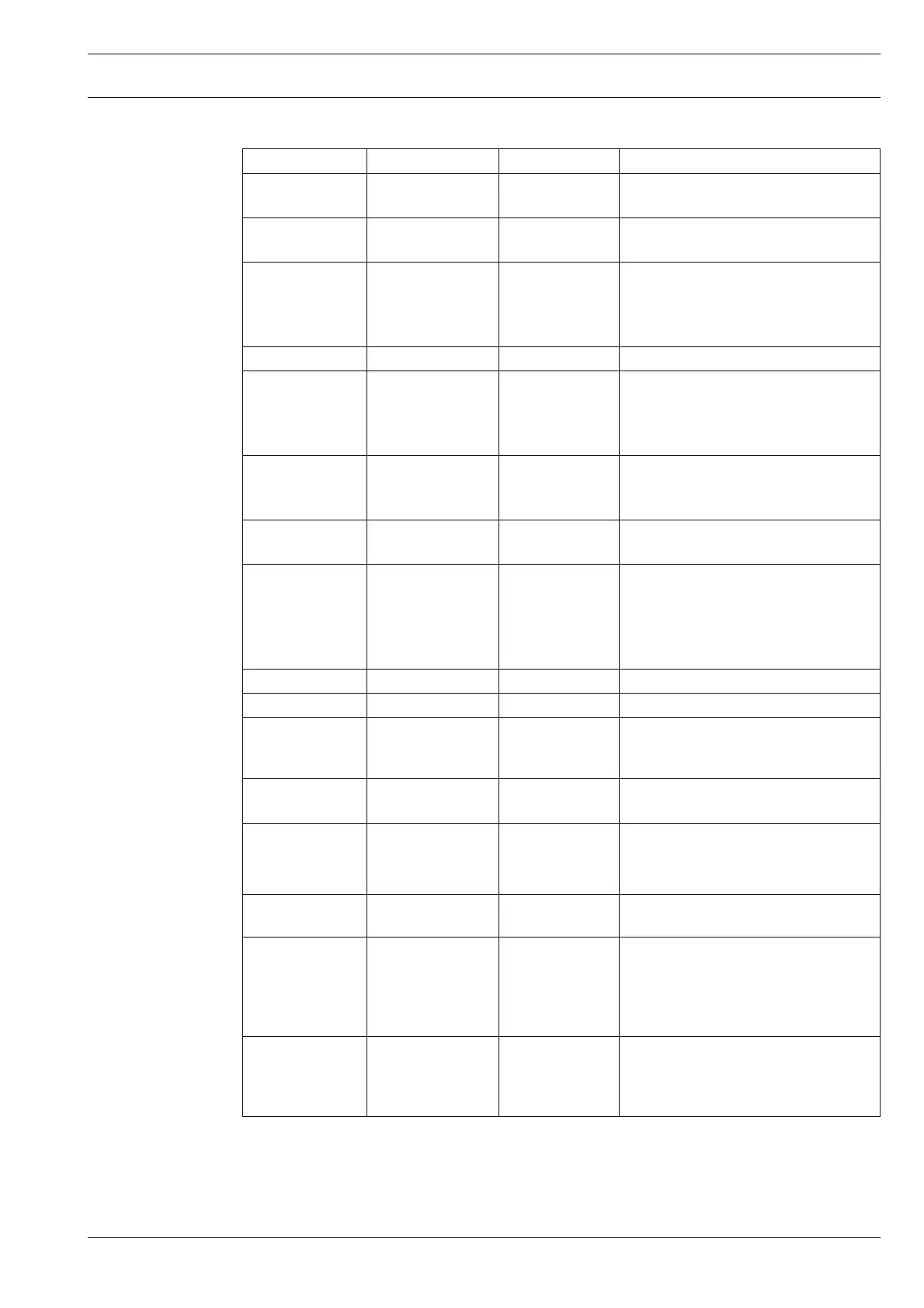

Parameter Value range Init-value Function

Temp sensors 1...2 2 Number of temperature sensors

(copy from confi g-page)

Flow sensor 0:OFF 1:ON 1:ON Air fl ow volume meter installed

(copy from confi g-page)

Sequence

continue

0:OFF 1:ON 1:ON 1: Automatic switching to next

sequence program0: Sequence

programs function as quick

selection keys

Enable Iron 0:OFF 1:ON 1:ON Iron key active when ON

Iron mode 0:OFF 1:ON 0:OFF 0: Switch to warm iron as fl ip-fl op

function

1: Switch to warm iron as level

function

E4 enable 0:OFF 1:ON 1:ON 1: Switch E4 (nozzle moved

forwards) requested

0: Switch E4 ignored

NiCr-Ni

▲

0:OFF 1:ON 1:ON 1: NiCr-Ni sensor (green wires)

0: Fe-CuNi sensor (blue wires)

Y1mode

▲

0:lp 1:hp 0:lp 0: Y1 (roller up/down) with pressure

reducer (low pressure)

1: Y1 without pressure reducer with

short counter pressure

(high pressure)

Tapespeed 10..60 m/min 30x0,1m/min Tape feed speed

Trailer 0..99 mm 10 mm Trailer

Overlap 0:OFF 1:ON 0:OFF 0: Tape feed after seam cycle end.

1: Tape feed after disengaging nozzle

(overlapping with trailer).

Cutter type 0..1 0 0: 8330 Tape cutter

1: 8330-060 Tape cutter

Y11delayTime 0..1000 x 10ms 0 x 10ms

Switch off delay of the

air blast tape

cutter (for locating tape) following

the engaging of the nozzle.

PullTapeBack 0..1 1 0: Always cut tape

1: Pull tape back to cut position

OpenRollerCut-

Tape

0..2 2 0: Open the rollers without tape cut

1: Open the rollers with pedal causes

a tape cut, open the rollers with

panel key don't cut

2: Open the rollers always cut tape

LightBarrier-

Mode

0..1 1 0: Light barrier always cause a tape

cut

1: Light barrier cause a tape cut if

armed by left pedal

▲

Parameters can by altered with the superpin only.

Loading...

Loading...