STATUS CODES

PROCLEIX

®

TIGRIS System Operator’s Manual A-1

Volume I: Operating the Instrument

Part # 902649EN Rev. A

The tables in this appendix contain descriptions of the codes that appear on the Results Report if an

error occurs during assay processing.

Contact Novartis Diagnostics Technical Service for further information about error conditions.

Instrument Processing Errors

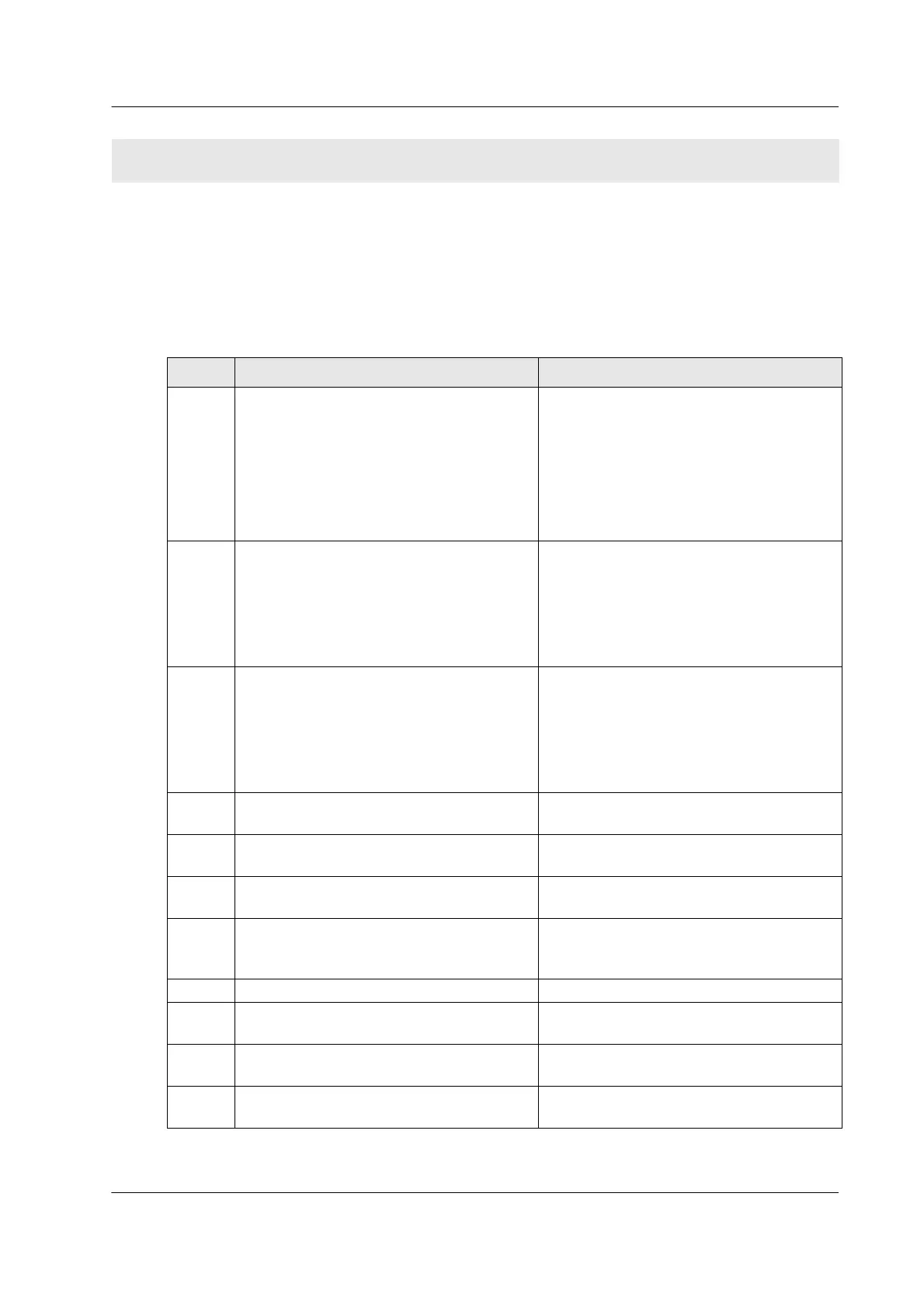

APPENDIX A. STATUS CODES

Code Cause Effect

APV Timing error.

An operation was not completed.

A robot or magnetic wash aspirator was

in the incorrect position.

The incorrect reagent was added.

The operation returned a non-zero status.

This is a non-fatal error. The affected

samples are marked Invalid.

APV Movement error.

Hardware error.

Incorrect MTU location.

An unmatched APL end message was

generated.

This is a fatal error. Every sample on the

worklist is marked Invalid.

CAN The sample had not been pipetted when

an operator clicked Stop Current or Stop

All.

The sample had not been pipetted when

a fatal error occurred, stopping

processing.

The affected samples are marked Invalid.

This error does not count towards the

10% invalid criterion.

CLT A clot was detected in the sample during

aspiration.

This is a non-fatal error. The affected

samples are marked Invalid.

FDF Oil, Auto Detect 1 or 2, or Wash Solution

dispense error.

This is a non-fatal error. The affected

samples are marked Invalid.

HB High background in the luminometer. This is a non-fatal error. The affected

samples are marked Invalid.

I There was no kinetic data for the sample

and neither an NTA nor an NTI flag was

applied to the sample.

This is a non-fatal error. The affected

samples are marked Invalid.

LDF System error. The affected samples are marked Invalid.

LPF The MTU could not be positioned

properly in the luminometer.

All samples in the affected MTU are

marked invalid.

M The sample ID was manually entered

using the keyboard.

The sample is not marked Invalid.

MFS Sample pipetting error. This is a non-fatal error. The affected

samples are marked Invalid.

Loading...

Loading...