Front suspension Section B

Description

Front suspension is provided by a Reliant

Motor

Group patented leading

arm

design

controlled by a heavy

duty

combined coil spring

and damper unit.

Chassis mounting is by means

of

two

rubber

bushes and caps locating onto brackets

we

ld

ed

to

the chassis front cross member. A bracket

on the upper cross member provides a mounting

for the damper unit.

Routine maintenance

Other than the greasing

of

the swivel pin and

periodic examination for signs

of

damage and

wear the front suspension assembly requires no

attention except for regular cleaning.

Before dismantling any part

of

the suspension

assembly, jack up the front

of

the vehicle under

the chassis side member and

fit

suitable stands.

Front

hub

and bearings

To

remove

(see

Figure

1)

1 Slacken

off

the front brake adjustment

(see

Section L).

2

Unscrew~

UNF countersunk screw and

remove brake drum.

3 Prise

out

the hub cap and remove split pin

from locking ring and

st

ub axle shaft.

4 Remove locking ring and unscrew front hub

retaining nut.

5 Withdraw front hub assembly complete

with

'0 ' washer, inner and outer taper bearings,

and

oil seal.

6 Remove outer taper bearing and then tap

out

bearing track from hub using a suitable drift.

7 Using the same drift from inside the hub tap

out

the inner bearing track. complete

with

bearing and oil seal.

8 Check components for wear and replace

if

necessary for subsequent reassembly.

To

reassemble

1 Locate inner bearing track in its housing

in

the hub and ensure

it

is firmly and squarely

seated. Then insert taper bearing into bearing

track.

2 Firmly

fit

oil

sea

l and

reta

iner in hub.

3 Repack the front hub

with

the approved

grease in the

area

between the inner bearing

and outer bearing location.

4 Locate outer bearing track in the hub, again

ensuring that

it

is firmly and squarely seated.

Then insert taper bearing into bearing track.

5 Position front hub assembly on the stub

axle and secure with

·o· washer and

fir

UNF

nut

, tightening until all resistance is taken up

when turning the hub.

2

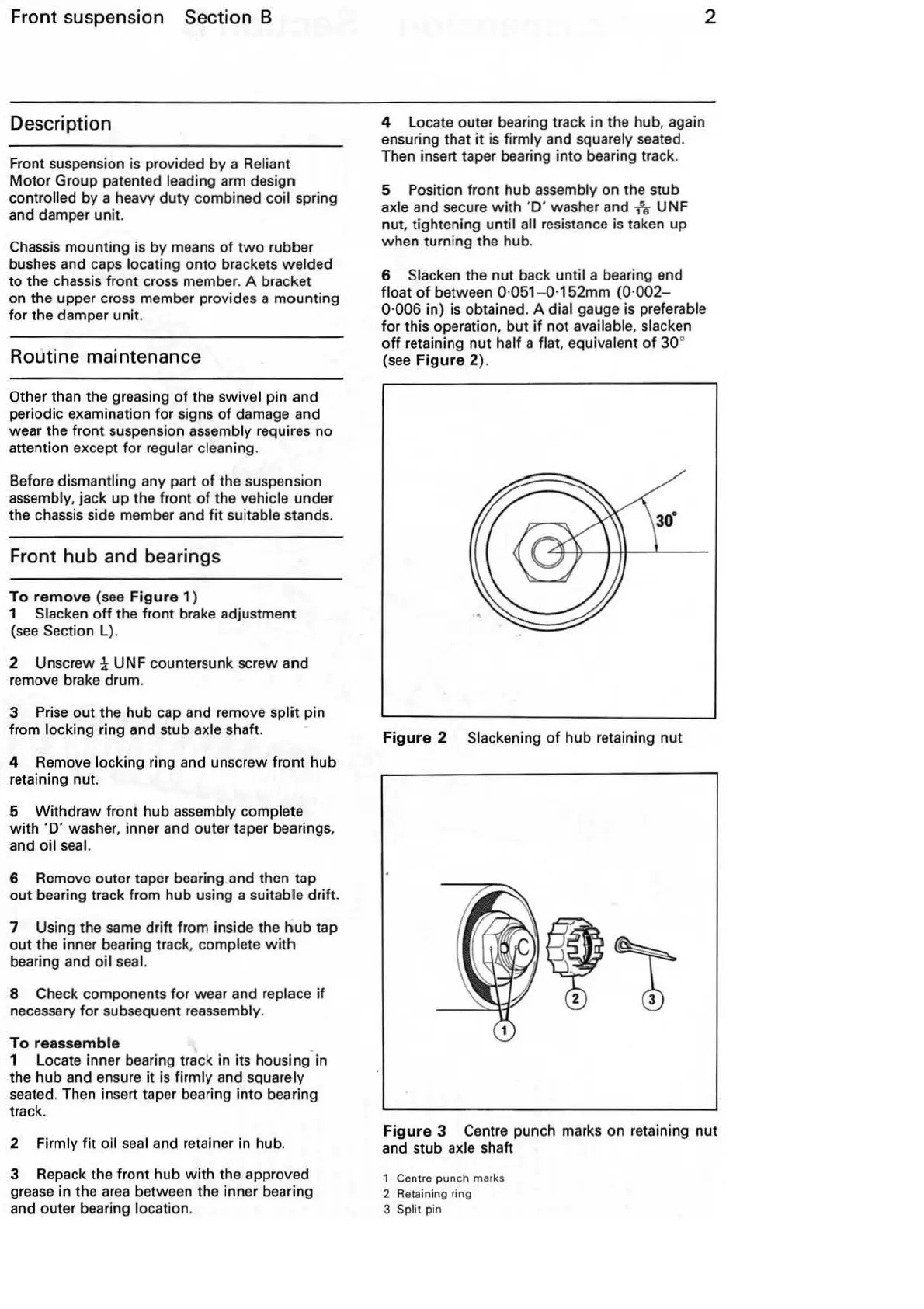

6 Slacken the nut back until a bearing end

float

of

between 0·

051

- 0·152mm

(0

·

002-

0·006 in) is obtained. A dial gauge is preferable

for this operation, but

if

not

available. slacken

off

retaining

nut

half a flat. equivalent

of

30

°

(see

Figure

2).

Figure

2 Slackening

of

hub retaining

nut

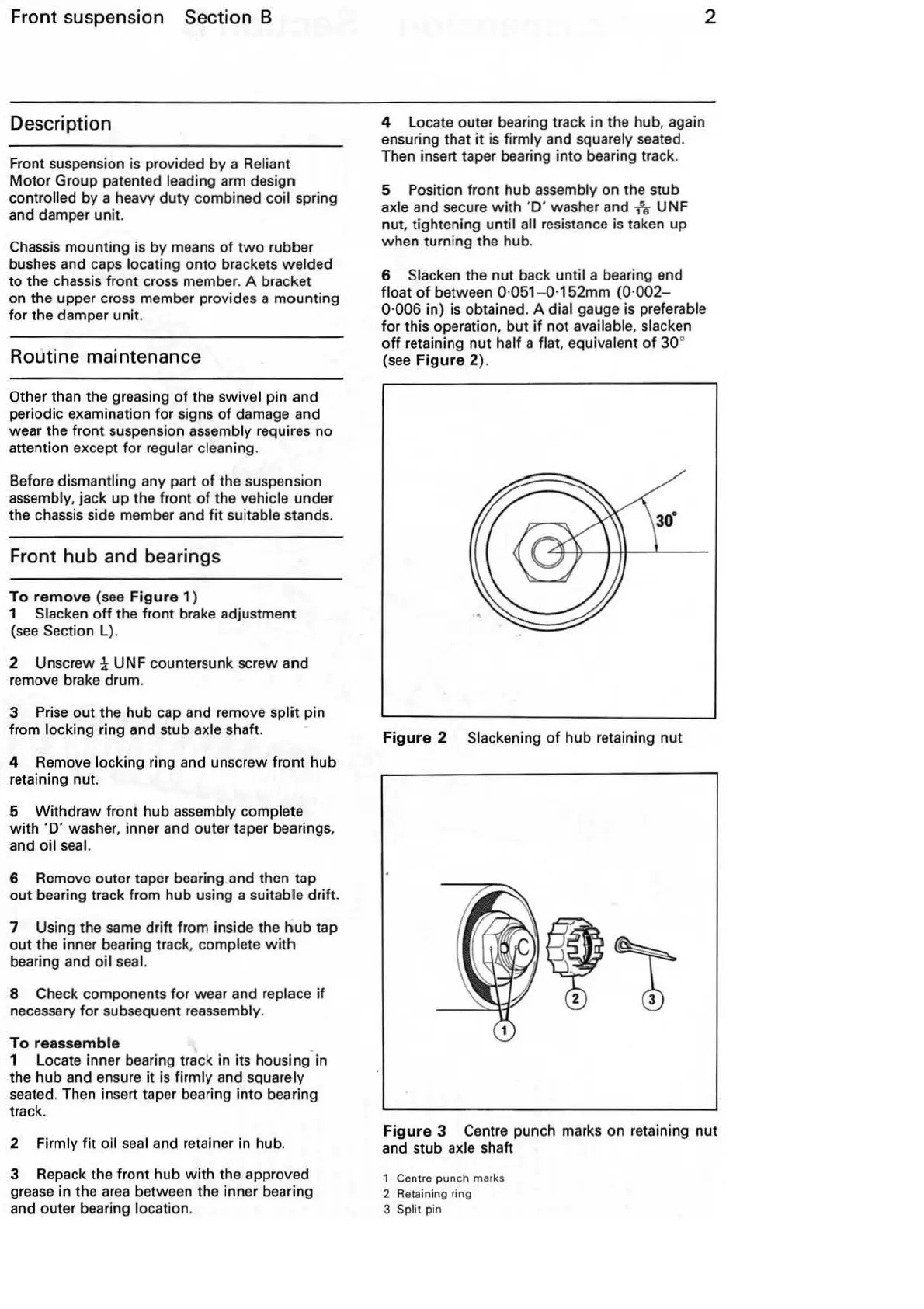

Figure

3 Centre punch marks on retaining

nut

and stub axle shaft

1 Centre punch marks

2 Retaining ring

3

Split pin

Loading...

Loading...