The engine Section F

7 Recut the valve seats

to

ensure that the seats

are concentric

with

the

va

l

ve

stem bore.

8 Relap valves

to

cylinder head seats, after

this operation carefu

lly

check valve seats to

ensure that no grinding paste particles are

present.

9 Fit n

ew

valve springs and

new

cotters

if

necessary.

10

Replace cylinder head.

Operation

11

-

Pi

stons, connecting

rods and bearings

(w

ith cylinder

head and sump removed)

1 Remove oil pump

as

.sembly (see

Operat

io

n

4)

.

2 Release locking plates, unscr

ew

eight bolts

and

rem

ove the four big end b

ea

ring caps (see

Fi

gure

15)

.

3 Remove the bearing shells from the caps

and con rods.

4 Carefully push the pistons, complete

with

con rods from the cylinder liners.

5 Immerse piston and con rod assemblies in

hot

water

for

a

few

minutes then release

gudgeon pin retaining circlips.

6 Using a suitable drift remove the gudgeon

pi

ns

and disconnect the con rods from the

pistons.

7

Rem

ove the small end bush

es

from the con

rods, and press in n

ew

on

es.

8 Having pressed in

new

small end bushes

check that they

will

accept

new

gudeon pins

for

it

may be necessary to ream

out

the bushes

with

an expanding reamer until a

tight

push

fit

is obtained.

Note

:

It

is important during this operation that

the bush is reamed squarely to the con rod

to

.

ensu

re

correct alignment.

9 Assemble

new

pisto

ns

Jo

the connecting

rods, securing in position with the gudgeon pins

and circlips.

It

may

be

necessary to heat the

pistons in hot water to facilitate the operation.

Ensure the

'f

ront' mark on the piston crowns

are

facing forward.

10

Before fitting t

he

piston rings, position in

appropriate liners for gapping, which should be

0·

17-0

·30mm (0·007- 0·012in).

11

11 Fit the piston rings, fitting the scraper ring

first, followed by the lower and then the upper

compression rings. The

'to

p' mark on the

compression rings must face uppermost.

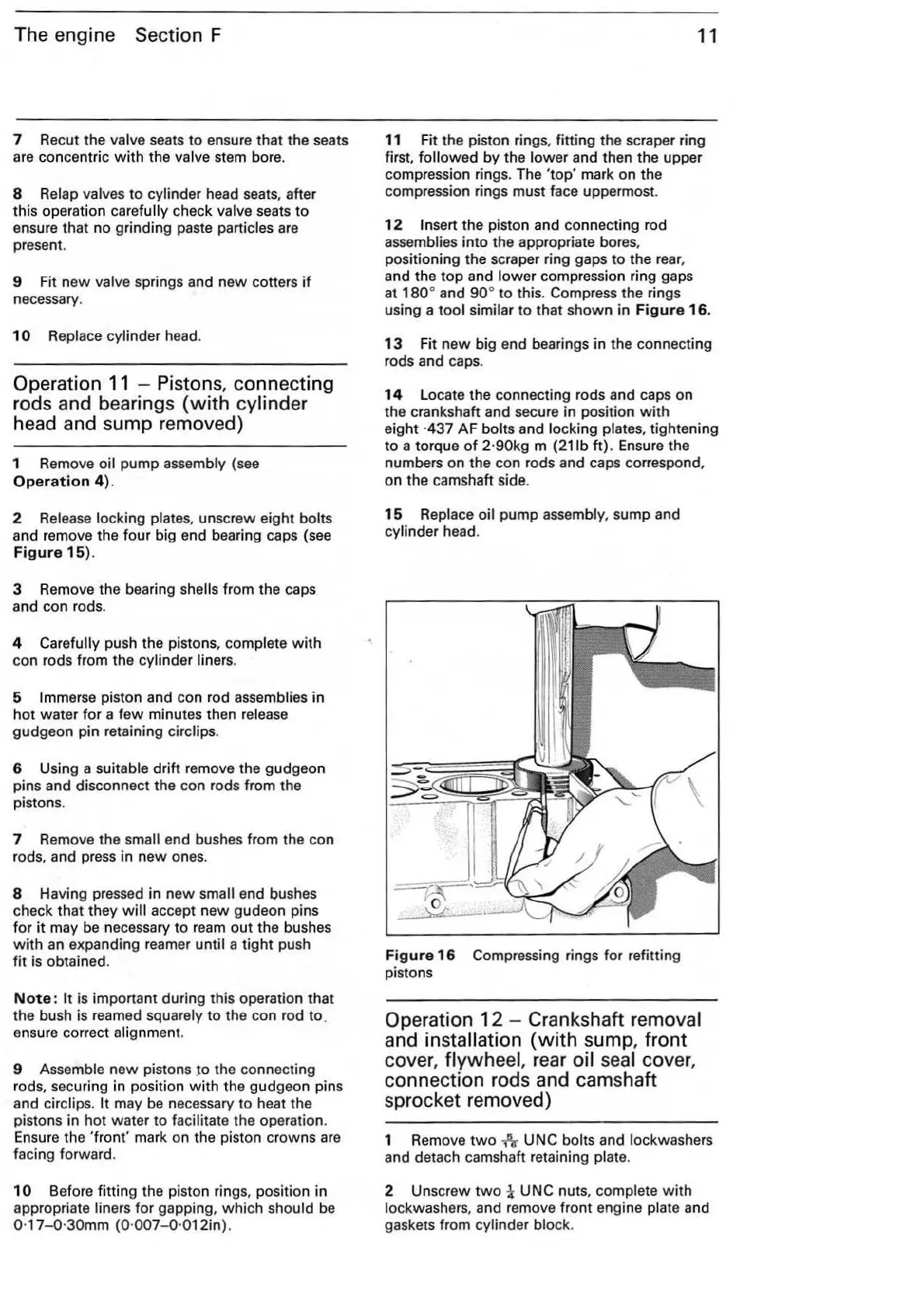

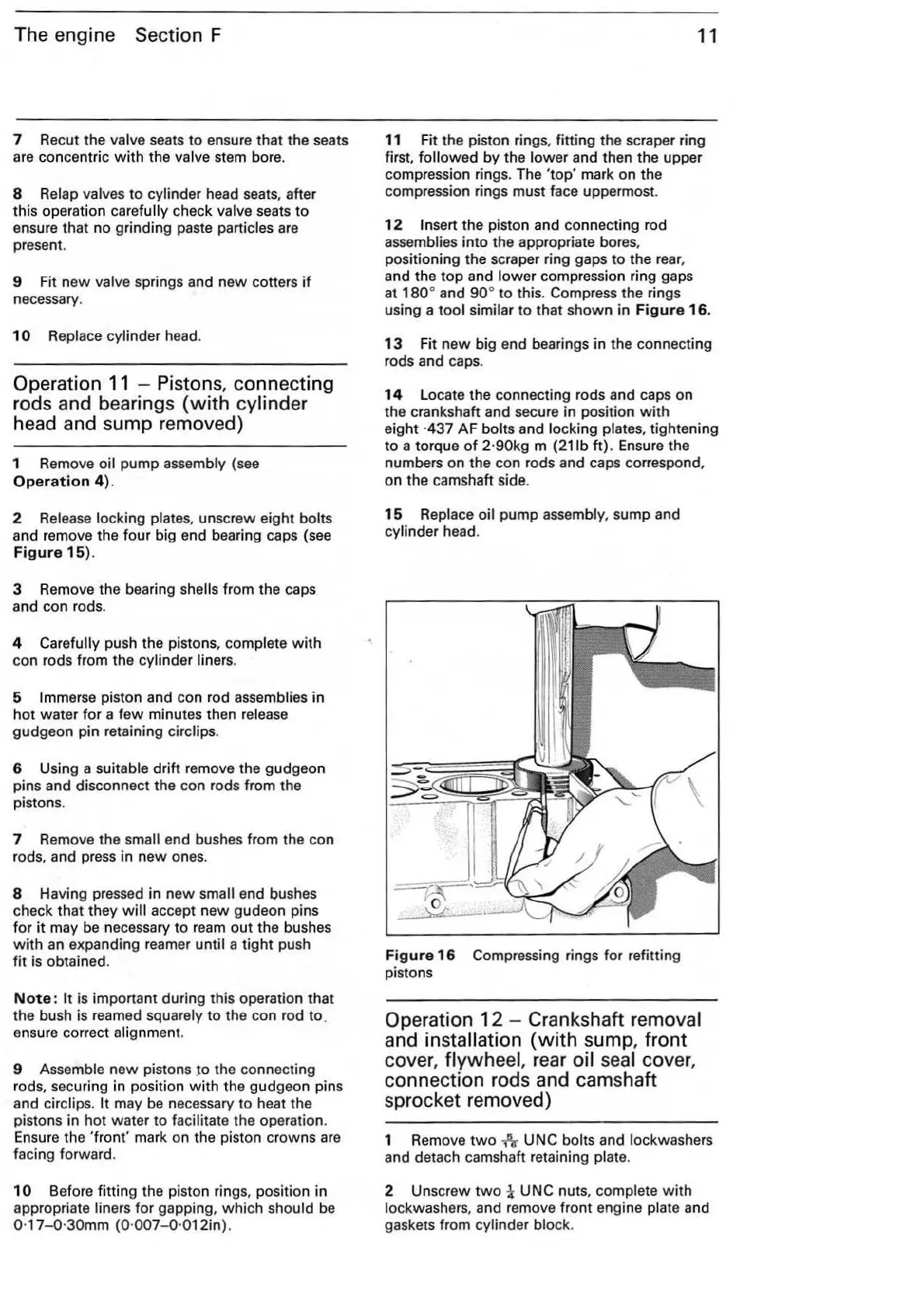

12

Insert the piston and connecting rod

assemblies into the appropriate bores,

positioning the scraper ring gaps

to

the rear,

and the

top

and l

owe

r compression ring gaps

at

180

° and

90

°

to

this. Compress the rings

using a

tool

similar

to

that

shown

in

Figure

16

.

13

Fi

t

new

big end bearings

in

the connecting

rods and caps.

14

Locate t

he

connecting rods and caps on

the crankshaft and secure in position

with

eight

·4

37 AF bolts and locking plates, tightening

to a torque

of

2·90kg m (21lb

ft)

.

Ensu

re the

numbers on the con rods and caps

co

rre

spond,

on the camshaft side.

15

Replace oil pump assembly, sump and

cylinder head.

Figure

16

Compressing rings for refitting

pistons

Operation

12

- Crankshaft removal

and

in

stallation

(with

sump, f

ront

cover,

flywh

ee

l, r

ea

r

oi

l

sea

l cover,

connection rods and camshaft

sprocket removed)

1 Remove

two

fir UNC bolts and lockwashers

and detach camshaft retaining plate.

2 Unscrew

two

i UNC nuts, complete

with

lockwashers, and remove front engine plate and

gaskets from cylinder block.

Loading...

Loading...