The engine Sec

ti

on F

3 Unscrew

four

-h

UNC

set screws and

remove rear engine plate from

cylinder block.

4 Remove four screws and detach the front

and rear bridge pieces from the

cylinder block.

5 Disconnect all three main bearing caps,

after removing six

i UNF nuts and washers,

two

each cap (see Fig

ur

e 15).

6 The crankshaft can

now

be

withdrawn

from the cylinder block.

7 Check crankshaft main bearing journals (see

engine specification for details).

8 Fit new main

bea

rings to crankshaft and

bearing caps.

9 Fit

new

thrust washers to the crankshaft

ensuring that the thrust

fa

ce

of

the first washer

makes

good

contact

with

the ground face

of

the

crankshaft.

1

0 Replace crankshaft to cylinder block, fit

main bearing caps

in

order, rear. centre, front,

and secure to block

with

six i UNF nu

ts

. Always

fit

new

main bearing cap nuts and tighten to a

torque

of

3·316kg m

(24

lb

ft).

11 Permitted end float

of

crankshaft is

0·

0254-0

·1524mm (0·

001-0

·006in).

12

12

Replace components in reverse order,

taking note

of

the

following

. When refitting front

and rear bridge pieces care should

be

taken to

ensure that their faces mate flush

with

the

cylinder block face.

Operation 13 - Camshaft removal

and installation

(with

timing chain

and sprocket removed)

1 Remove engine assembly (see

Operation

1 ).

2 Unscrew

two

-h

UNF nuts and

lift

off

rocker cover and sealing gasket.

3 Unscrew four

i UNF nuts and washers

from the rocker shaft support brackets and

remove the complete rocker assembly.

4 Withdraw the eight push rods keeping

them in their correct order.

5 Remove sump (see

Operatio

n 3).

6 Unscrew

two

-h nuts, complete

with

lockwashe

rs

, and remove oil pump assembly,

complete

with

filter, from cylinder block.

7 Knock

out

the pin

se

curing thrust

muff

to

distributor and oil pump drive shaft

which

can

then

be

removed upwards through the

distributor location.

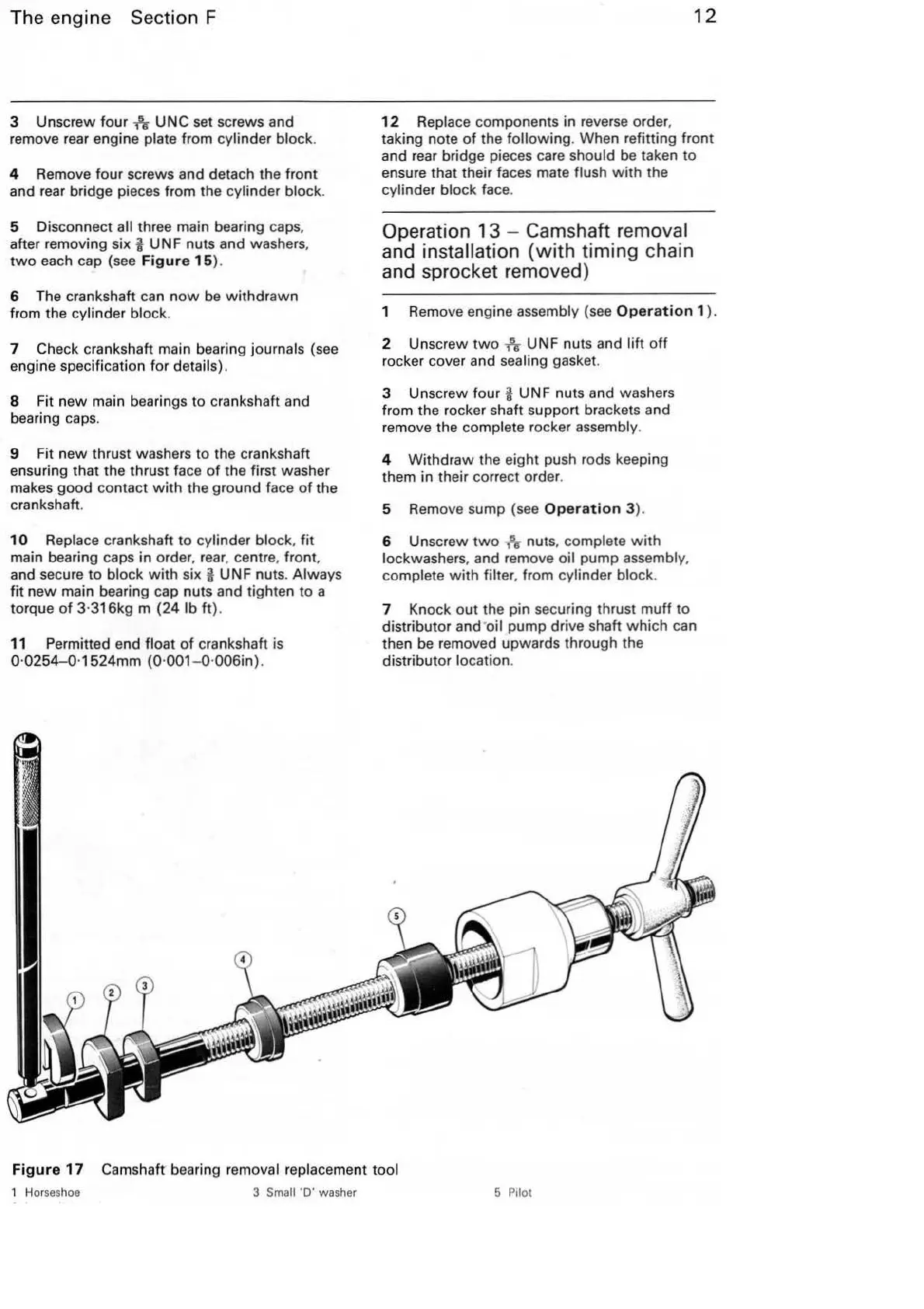

Fig

ur

e

17

Camshaft bearing removal replacement

too

l

1 Horseshoe 3 Small

'D'

washer 5 PilOt

Loading...

Loading...