If the updated value PV > SP, then the special function reduces the value of AQ.

If the updated value PV < SP, then the special function increases the value of

AQ.

Dir = downwards/- (timing diagram number 2)

If the updated value PV > SP, then the special function increases the value of

AQ.

If the updated value PV < SP, then the special function reduces the value of AQ.

With a disturbance, AQ continues to increase / decrease until the updated value PV

again corresponds to SP. The speed with which AQ changes depends on the

parameters KC and TI. If the input PV exceeds the parameter Max., then the updated

value PV is set to the value of Max.. If the PV falls short of the parameter Min., then

the updated value PV is set to the value of Min.

If the input R is set to 1, then the AQ output is reset. As long as R is set, the input A/M

is disabled.

Sampling Time

The sampling time is fixed at 500 ms.

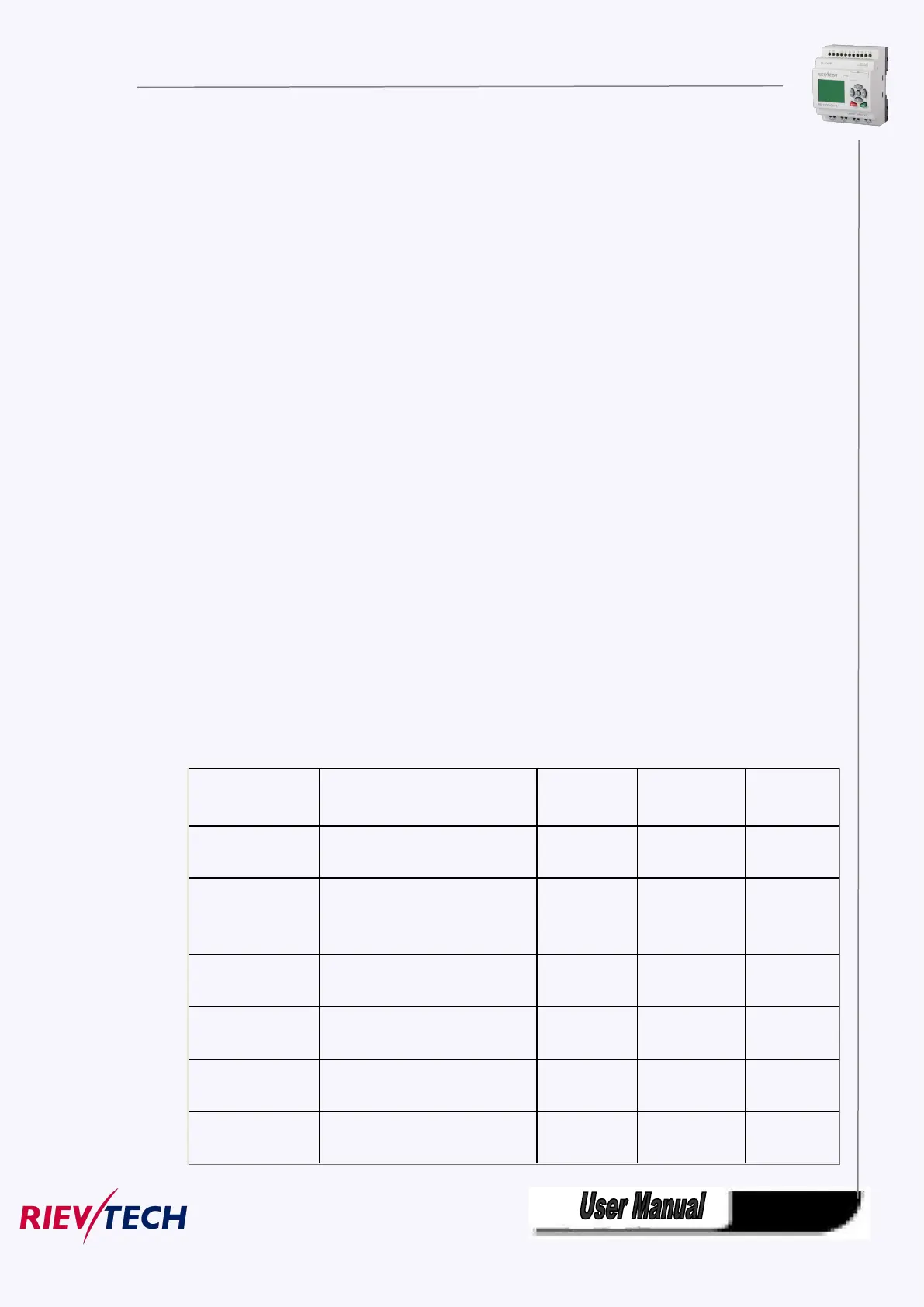

Parameter sets

In order to simplify the use of the PI controller, the parameters for KC, TI and Dir are

already given as sets for the following applications:

Temperature, cooling control of

small spaces; small volumes

Heating, ventilation, temperature,

cooling control of large spaces;

large volumes

Quick pressure change,

compressor control

Slow pressure change, differential

pressure control (flow controller)

Vat and/or reservoir filling without

drain

Vat and/or reservoir filling with

drain

Loading...

Loading...