ROBOT S6

Check lubricant level.

Do not top-up and/or replace the lubricant in reduction gears and gearmotors lubricated for

life.

Keep to the recommended lubrication frequency to get top machine performances and a longer

operating life.

Use lubricants (oils or grease) recommended by the manufacturer or with similar chemical-

physical features.

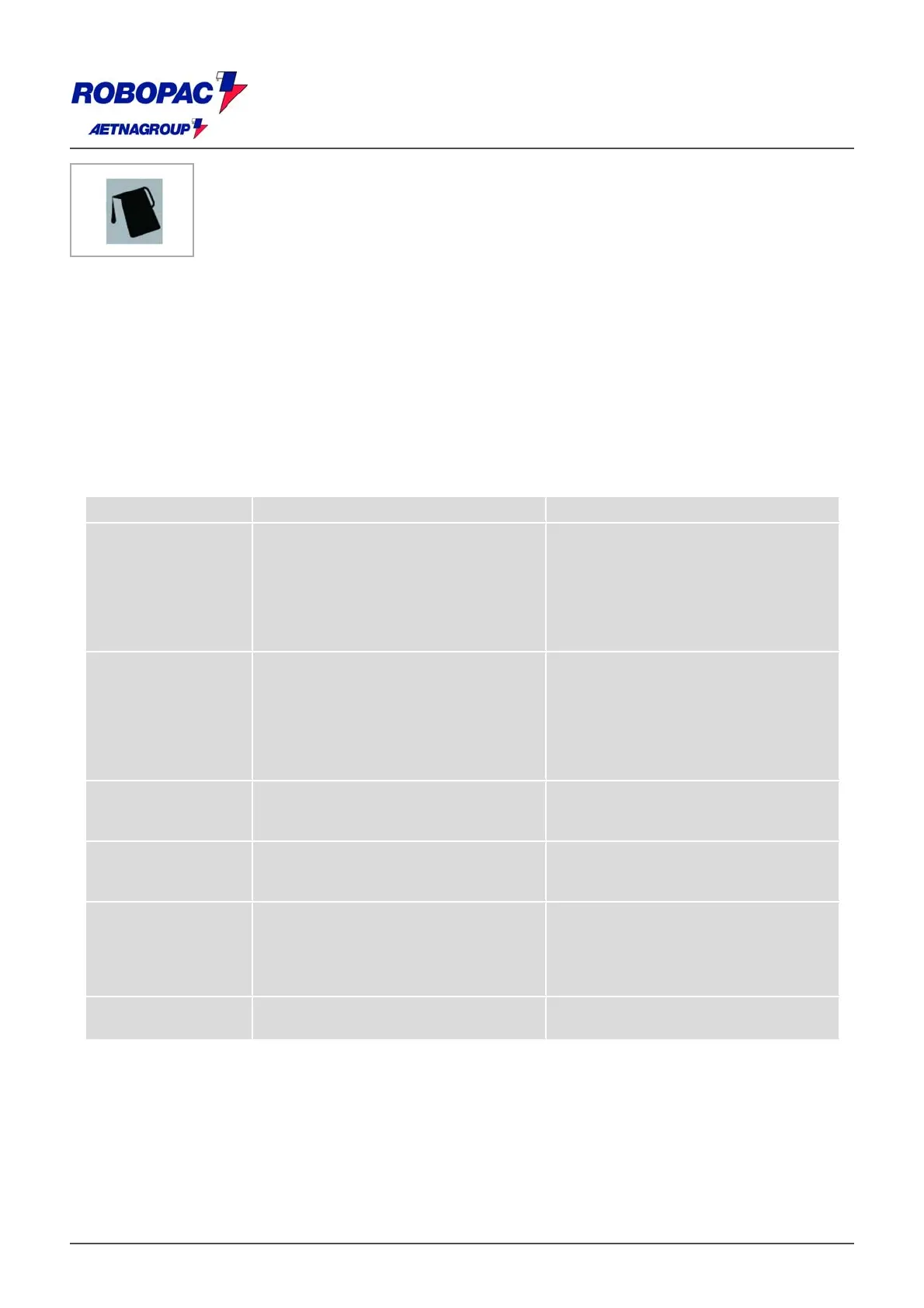

7.4. LUBRICANTS TABLE

he table below specifies the lubricants recommended by the Manufacturer for each component and/or area of

the machine.

Use lubricants (oils or grease) recommended by the manufacturer or with similar chemical-

physical features.

Lubricant specifications

Type of lubricant Name Parts to be lubricated

Mineral oil 23°C / 50°C - 320 CST 40°C

MELLANA OIL 320 IP

SPARTAN EP 320 ESSO

BLASIA 320 AGIP

MOBILGEAR 632 MOBIL

OMALA EP 320 SHELL

ENERGOL GR-XP 320 BP

Gear motor

Mineral oil 32°C / 50°C - 460 CST 40°C

MELLANA OIL 460 IP

SPARTAN EP 460 ESSO

BLASIA 460 AGIP

MOBILGEAR 634 MOBIL

OMALA EP 460 SHELL

ENERGOL GR-XP 460 BP

Worm gear motor

Grease

ELESIA COMPOUND B I

STRUCTOVIS P LIQUID KLUBER

OTALCARTER SYOO TOTA

Gear and worm gear motor

Synthetic oil

ELESIA OIL I

SYNTHESO D 220 EP KLUBER

BLASIA S 220 AGIP

Gear and worm gear motor

Lithium grease ALVANIA R2 SHELL

HL 2 ARAL

ENERGREASE LS2 BP

BEACON 2 ESSO

MOBILIX MOBIL

Bearings with support

Synthetic oil -5°C / +5°C VG 68 (SAE 20)

+5°C / +25°C VG 100 (SAE 30)

Spool carriage chain

Important

Do not mix oils of different makes and specifications.

Loading...

Loading...