ROBOT S6

3.1.1.ROLL-HOLDER CARRIAGE SPECIFICATIONS

Type of reel

holdingcarriage

General Requirements

FRD FRD and “FRD for net” type reel carriage; with friction roller,

mechanical brake and manual film stretch adjustment.

FR FR type reel carriage with friction roller, electromagnetic brake and

film stretchadjustment from the control panel.

PDS PDS-type spool carriage; with driven pre-stretch rollers and

electronic film tensioning.

Pre-stretching is adjustable from control panel (0%÷250%).

PVS PVS type reel carriage: with dual drive pre-stretch rollers and

electronically controlledfilm tensioning.

Pre-stretching is adjustable from control panel (0%÷400%).

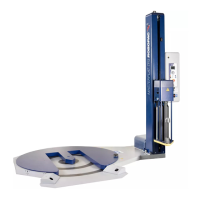

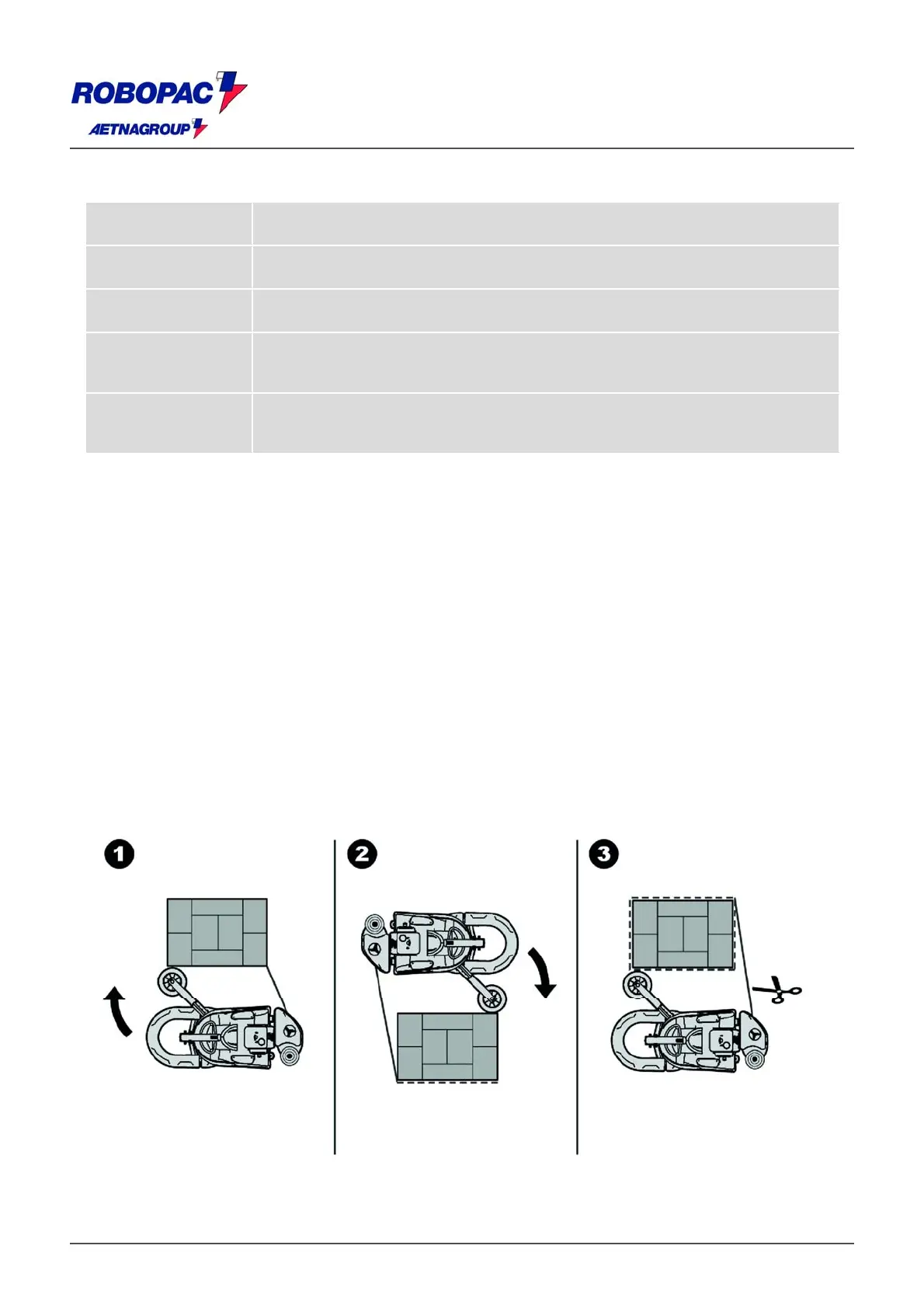

3.2. OPERATING CYCLE AND WRAPPING MODES

he figure below shows the operating cycle. A brief description and illustration of the wrapping modes (single

and double) are also provided.

3.2.1.RUNNING CYCLE

‒Phase 1

he Operator approaches the machine until the feeler wheel is in contact with the pallet, then ties the

end of the film to the pallet and starts the wrapping cycle.

‒Phase 2

he machine turns clock-wise around the pallet, while the roll-holder carriage lifts and releases the fil

according to the parameter settings.

‒Phase 3

Upon completion of the wrapping phase, the machine stops.

After cutting the film (manually or in automatic mode) the machine can be moved to the following pallet

to be wrapped.

3.2.2.MODES OF WRAPPING

Loading...

Loading...