14 Rockwell Automation Publication IASIMP-QS005H-EN-P - April 2016

Chapter 1 Risk Assessment and System Design

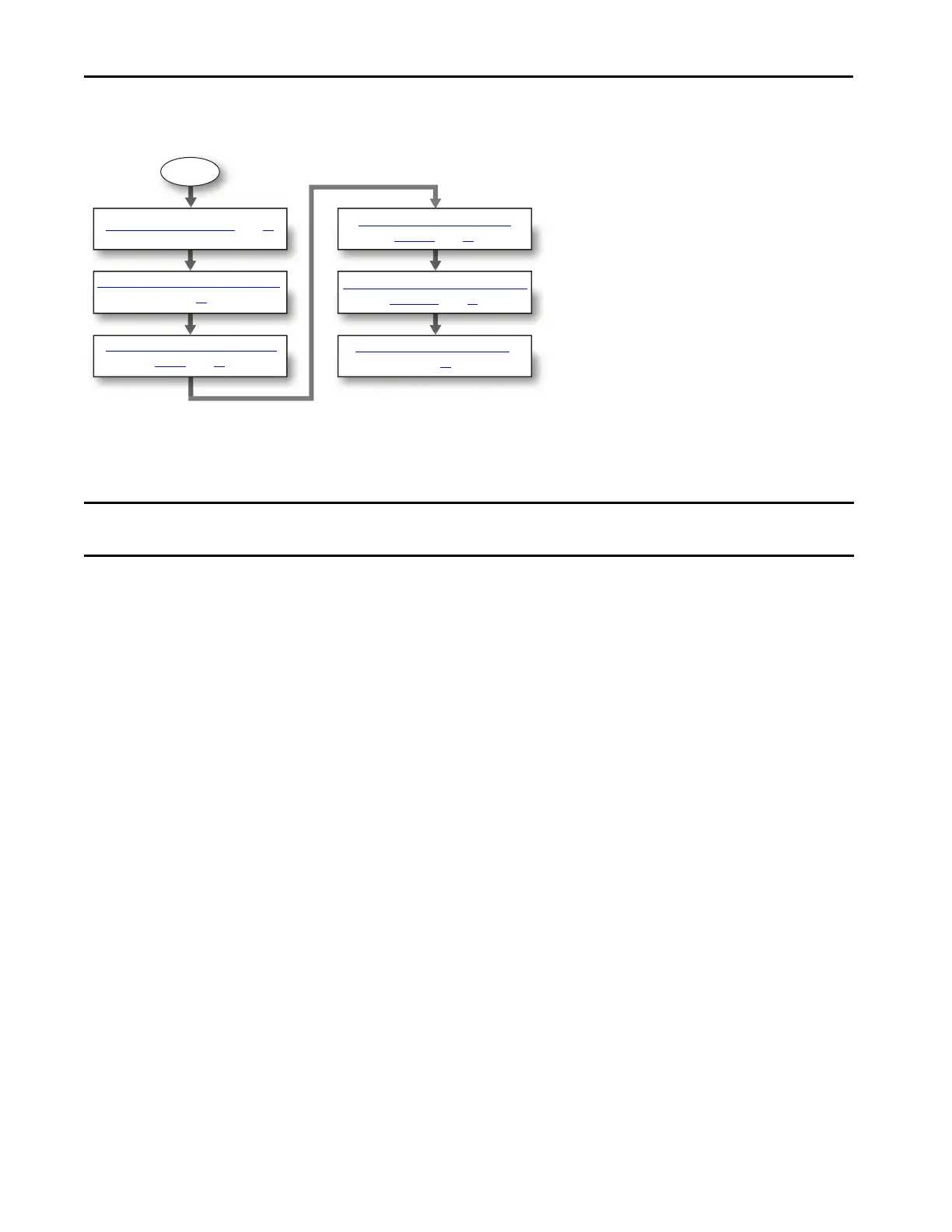

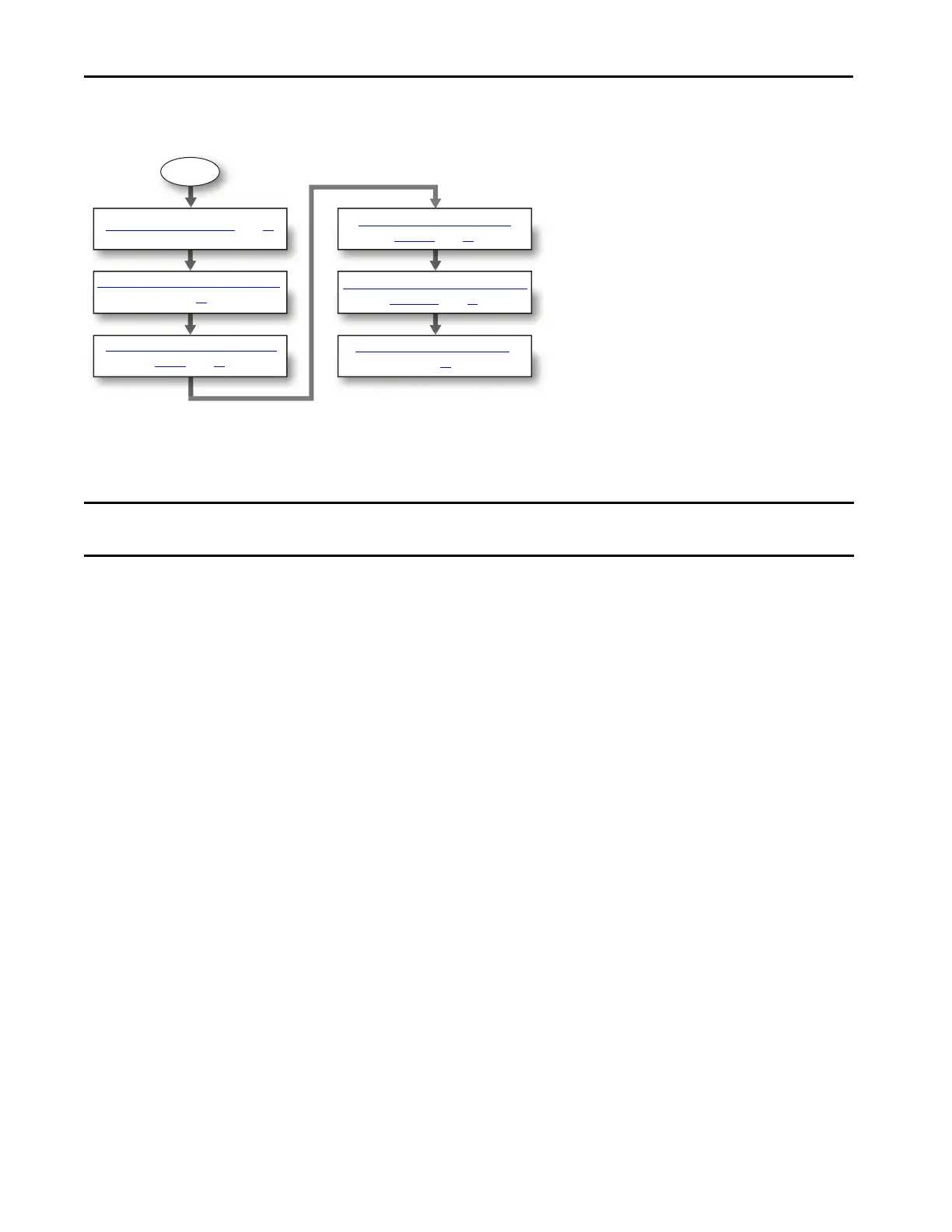

Follow These Steps

Safety Strategy Fundamentals

To devise a proper safety strategy, these steps must be addressed.

1. Risk Assessment: based on a clear understanding of the machine limits and functions and the tasks that may be

required to be performed throughout its life.

2. Risk Reduction: performed if necessary with safety measures selected and implemented based on the

performance requirements dictated by the risk assessment methodology.

Risk Assessment Methodologies dictate that the hierarchy of safety controls be followed, implementing system

redesign measures, if possible, to totally eliminate the risk.

A hazard control technique must be defined for each hazardous motion, including each mode of operation (such

as Automatic, Jog, or Cycle Stop) and each demand on the safety system (such as E-stop device activated or safety

gate opened). This is essential so that the energy source is properly controlled in all interactions with the machine

and all demand scenarios on the safety system.

Start

Safety Strategy Fundamentals

, page 14

Conducting a Team-based Risk Assessment,

page 16

Select Mitigation Techniques for Hazard

Control, page 22

Incorporate Protective Systems and

Measures, page 22

Safety Specification Example for Robot Cell

Application, page 23

How Rockwell Automation Can Help,

page 25

IMPORTANT The information in this section is not advocated as the definitive method. Individual circumstances may dictate a different

approach. It is intended as a general guideline to encourage a methodical and documented structure.

Loading...

Loading...