Rockwell Automation Publication IASIMP-QS005H-EN-P - April 2016 21

Risk Assessment and System Design Chapter 1

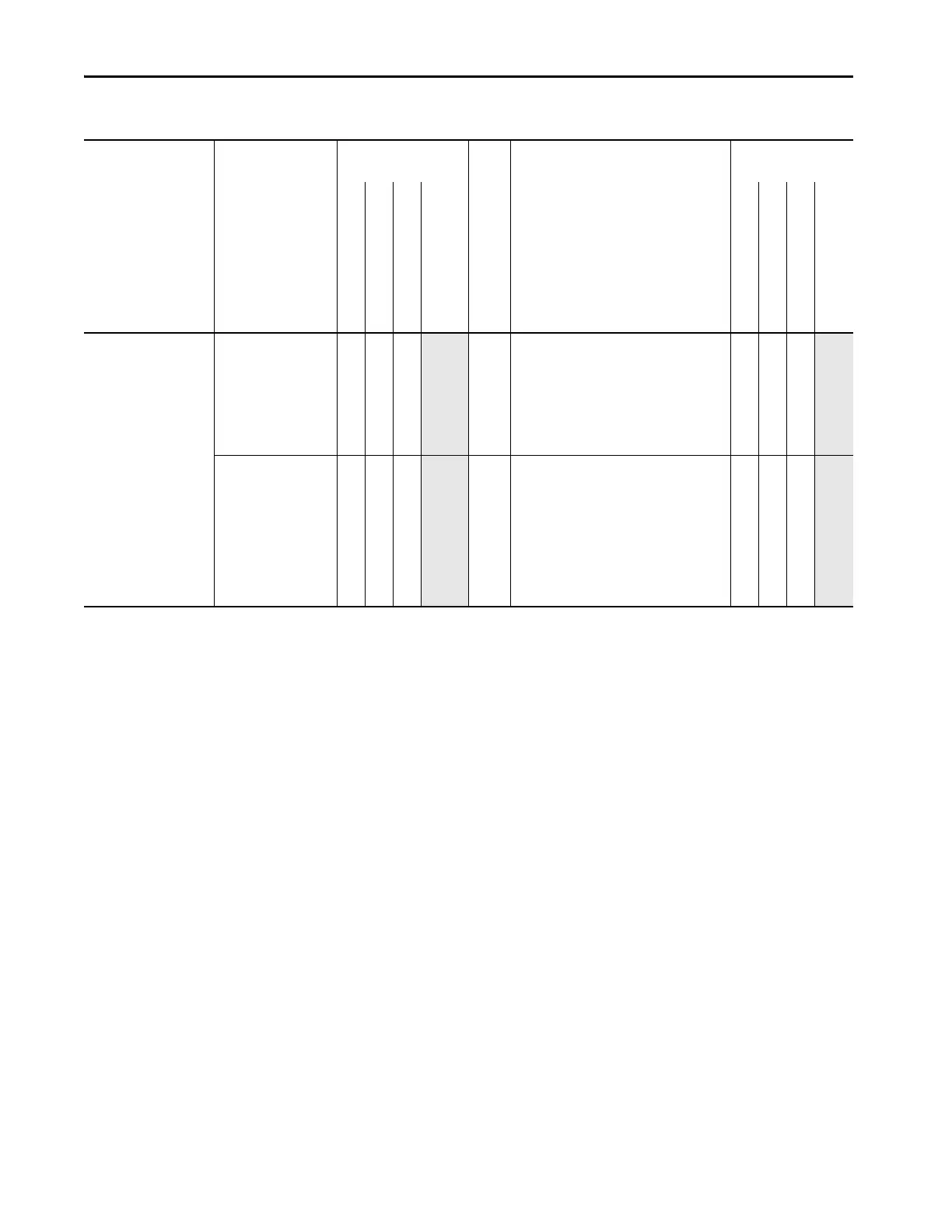

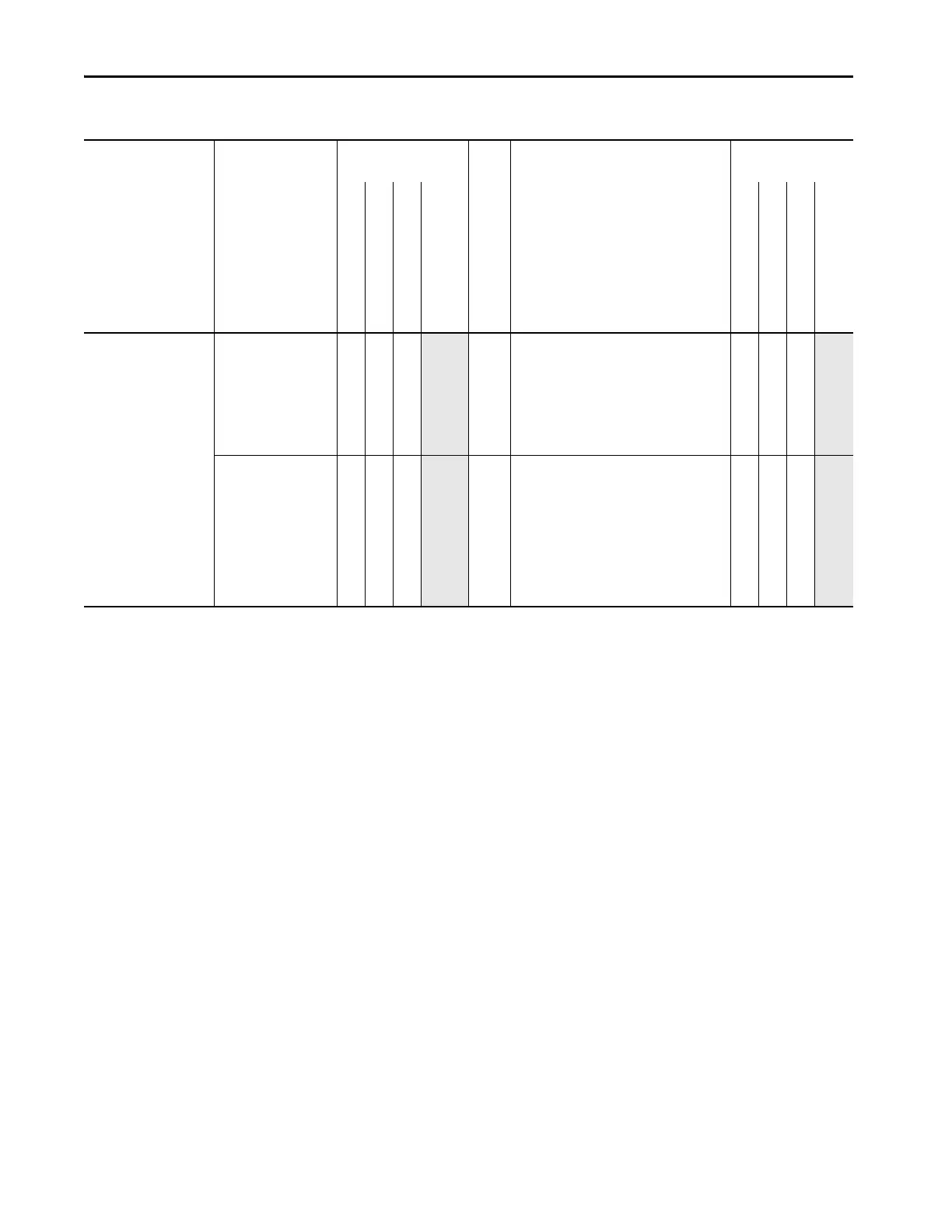

Table 3 - Risk Assessment Worksheet - Panel Assembly Feed Conveyor

Steps

Potential Incidents or

Accidents

Prior to Safeguards

Current Safeguards

Recommendations

With Safeguards

Severity of Injury

Frequency (Exposure)

Avoidance

Risk Reduction

Category

(1)

(1) Risk Ratings of R1, R2A, R2B, R3, R4 correspond to the Safety Control Circuit Performance requirements of ANSI/RIA R15.06-1999. An R1 rating represents a control reliable circuit with continuous

checking for electrical and fluid power circuits. See the standard for a complete definition of performance requirements for the related risk ratings.

Severity of Injury

Frequency (Exposure)

Avoidance

Residual Risk<Footnote>(1)

Tasks in the general area of

the work cell where a

person may be tempted to

enter the hazardous area.

Mechanical impact: Pinch

or crush hazard due to

robot motion.

S2 F2 A2 R1 Safeguarding:

a. Use hard guards to prevent access to the

hazardous area.

b. Use a light curtain to prevent access to

guarded area, such as workers climbing

on the conveyor.

c. Install a properly-rated safety control

system.

S1 F1 A1 R4

Mechanical impact: Pinch

or crush hazard due to

conveyor power

transmission.

S2 F2 A1 R2A Hard-guarding:

a. Make sure that the power transmission

equipment and belts or pulleys are

properly guarded.

b. Install awareness signs to communicate

that equipment must not be operated

without guards.

c. Verify that the training covers what guards

are in place and that safety inspections

validate that guards are present.

S1 F1 A1 R4

Loading...

Loading...