Rockwell Automation Publication 2099-UM001G-EN-P - December 2022 173

Interconnect Diagrams Appendix B

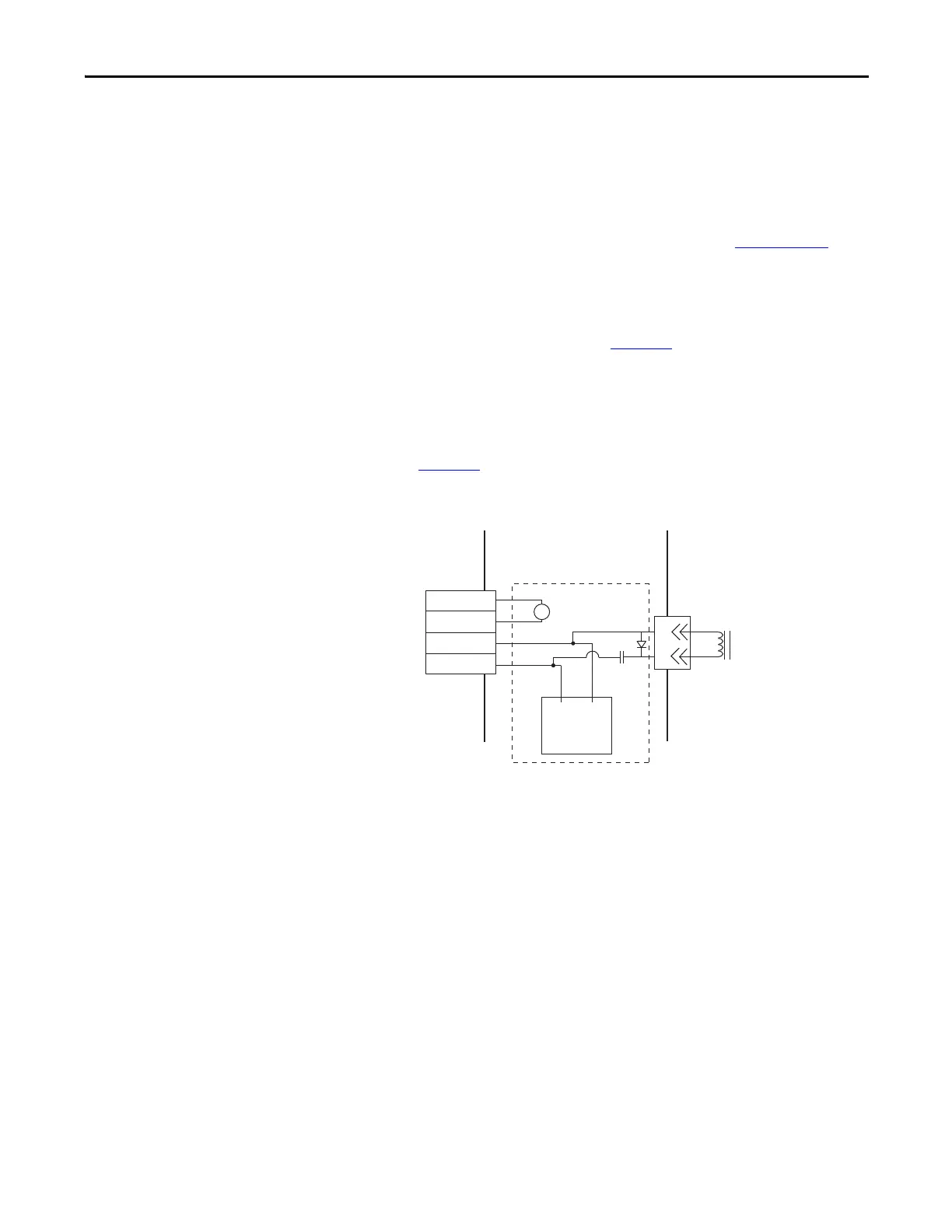

Customer-supplied 24V DC Power Supply Notes

• The contact connected to GPR1+ and GPR1- is rated 2 Amps inductive

@ 250V AC/30V DC maximum.

• Kinetix MPx motors with a brake have various coil current requirements.

Refer to the Kinetix 7000 Design Guide, publication KNX-RM007

for

coil current requirements.

• For motors that utilize above 2 Amp coil current it is recommended that a

customer-supplied external device, such as an interposing relay, be used

between the drive and motor. See Figure 83

below.

• A customer-supplied diode or metal oxide varistor (MOV) is

recommended for use with an interposing relay to prevent an electrical arc

that may occur before the brake coil power dissipates. Use of an MOV can

also reduce the amount of time required to mechanically engage the brake.

See Figure 83

below.

Figure 83 - Customer-supplied 24V DC Power Supply Wiring Example

BR+

BR-

A

C

3

2

4

1

GPR1-

GPR1+

COM

24VDC

24VDC

Supply

+ -

C1

C1

*Dashed lines

denote customer

supplied components.

Kinetix 7000

Drive

MPL Motor

Loading...

Loading...