Rockwell Automation Publication 750-TG100B-EN-P - June 2019 131

Frame 7 Components Chapter 6

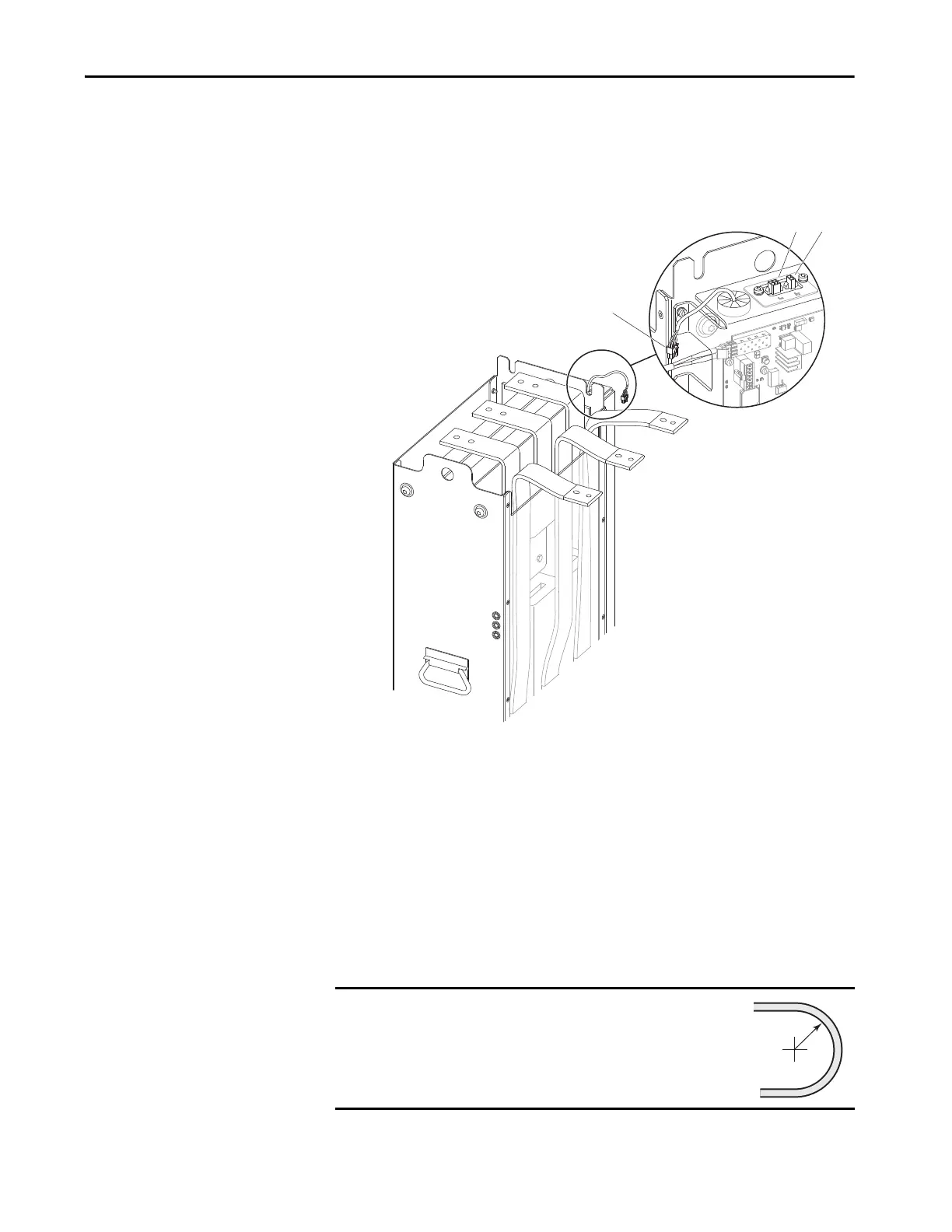

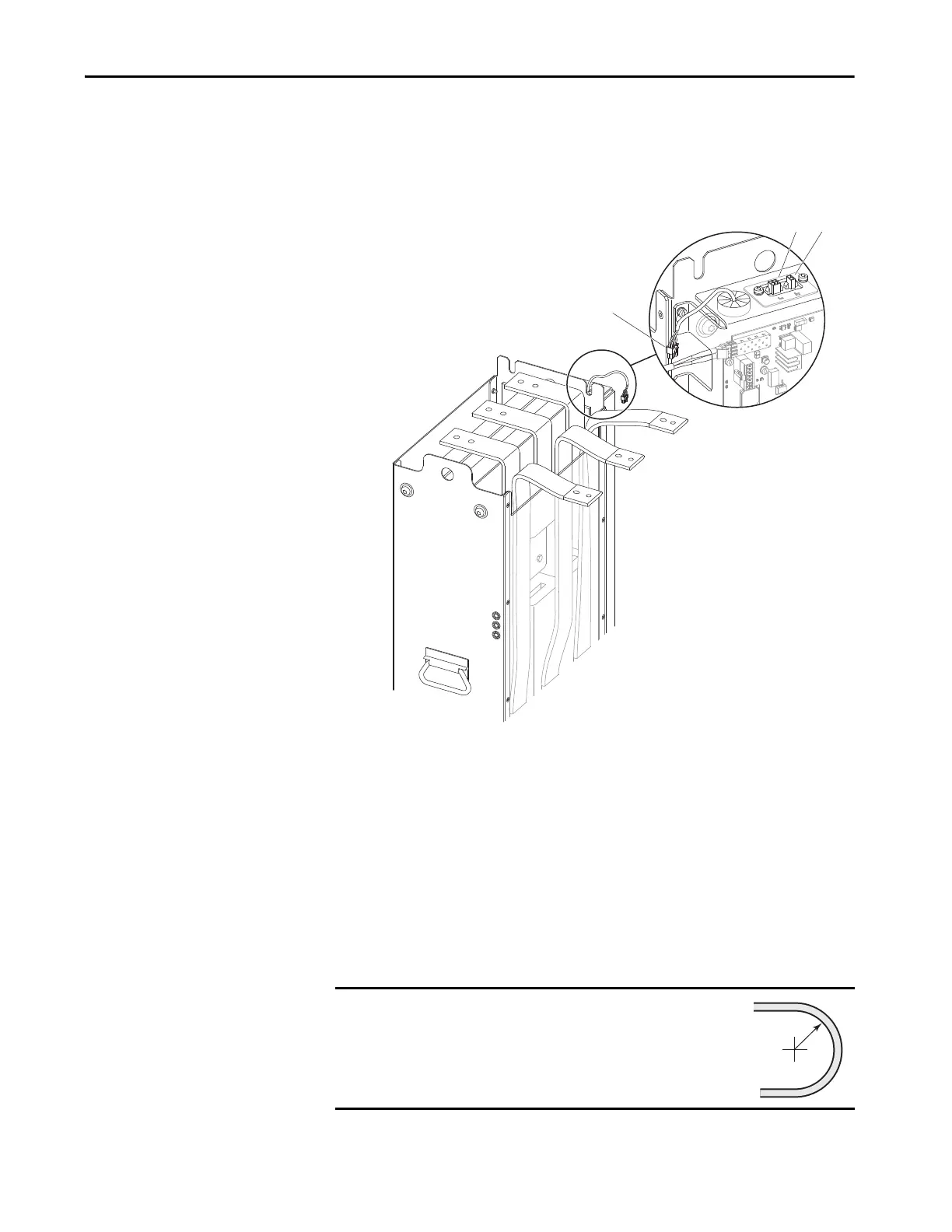

15. Disconnect the AC fuse wire harness connector P1 from connector J1 on

the LCL filter I/O panel.

16. Disconnect the 240V AC power wire harness connector P2 from J2 on the

LCL filter module I/O panel.

17. Remove the LCL filter module from the enclosure.

Install the LCL Filter Module in the Enclosure

Install the LCL filter module into the enclosure in the reverse order of removal.

When installing the fiber-optic cables:

1. Remove the transceiver from the fiber-optic port on the power layer

interface circuit board.

IMPORTANT

Minimum inside bend radius for fiber-optic cable is 50 mm

(2 in.). Any bends with a shorter inside radius can

permanently damage the fiber-optic cable. Signal

attenuation increases as inside bend radius is decreased.

Loading...

Loading...