22 Rockwell Automation Publication 750-TG100B-EN-P - June 2019

Chapter 1 Before You Begin Tests, Maintenance, or Repairs

Commonly Used Tools

Tab le 2 includes the tools that are needed for test measurements, basic

maintenance, and service repairs.

Software Tools

Connected Components Workbench™ software is an application that can be used

to upload and download parameter configuration and monitor system

parameters. Connected Components Workbench version 10.xx or later is

required for use with PowerFlex 755T products.

IMPORTANT Care must be taken to be sure that tools and/or hardware components do not

fall into open drive assemblies. Do not energize the drive unless all loose tools

and/or hardware components have been removed from the drive assemblies

and enclosure.

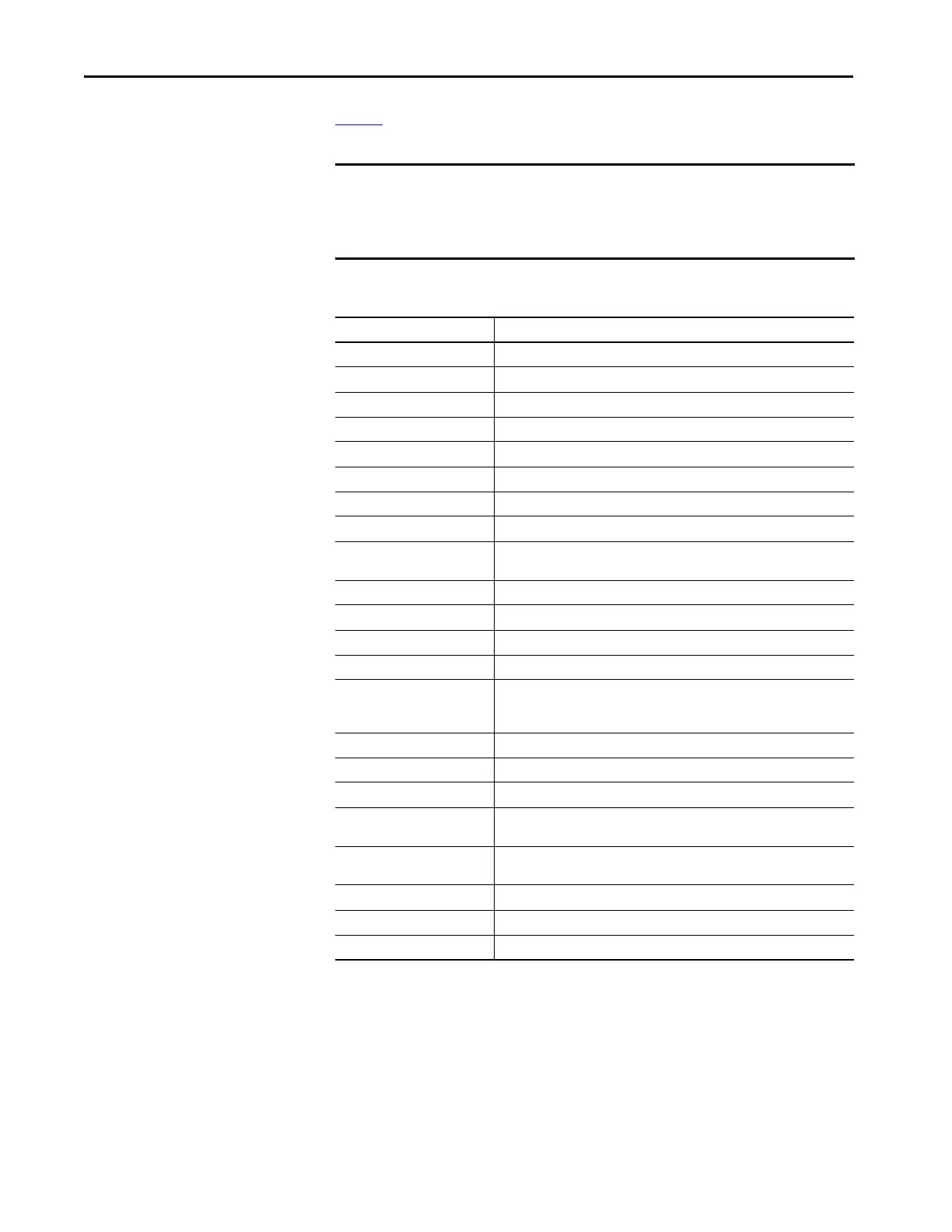

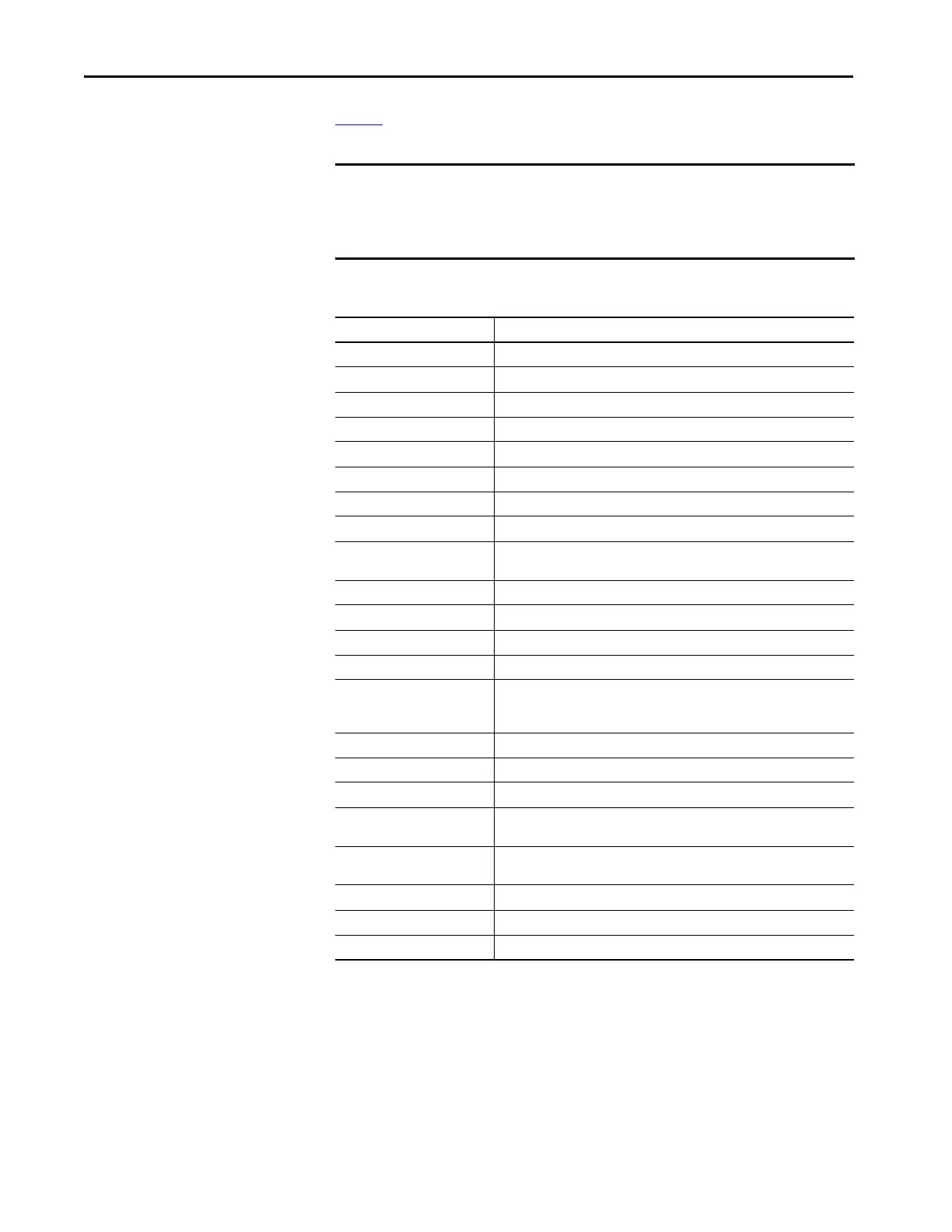

Table 2 - Service Tools

Tool Description Details

Allen socket wrench 3 mm

Box wrench 7 mm, 8 mm, 10 mm, 13 mm, 15 mm, 17 mm, 19 mm, 22 mm

Crimp tools For cable terminals 1.5...240

Current clamp 1000 A (AC, rms), signal output

ESD-protected place of work Work surface, Floor cover, seat, and ground connections

ESD-protective clothing Wrist wrap, shoes, overall clothing (coat)

Flash light –

Flat-nose screwdriver 3 mm (0.12 in.), 5 mm (0.19 in.), 6.4 mm (0.25 in.)

Torx, star, or hexalobular screw

driver/bit

#15, #20, #25, #30, #40, #45

Hexagonal socket wrench 2.5 mm, 7 mm, 8 mm, 10 mm, 12 mm, 13 mm, 17 mm, 18 mm

Insulation tester 1000V DC

Level –

Lift strap 5/16 in. J-hook style, 24 in. long, 1000 lb. Minimum

Multi-meter Digital multi-meter, capable of AC and DC voltage, continuity, resistance,

capacitance measurements, and forward diode bias tests. Fluke model 87 III or

equivalent.

Nose pliers –

Oscilloscope Portable, digitizing, dual channel scope, with isolation

Phillips screwdriver/bit #1, #2

Module service cart The optional module service cart (20-750-MCART1) is recommended to handle

and transport power and filter modules.

Module storage hardware Module storage hardware (20-750-MINV-ATIP) helps to stabilize power and filter

modules during temporary storage after removal.

Torque wrench 1...12 N

•m (8.8…106 lb•in)

Torque wrench 6...50 N

•m (53…443 lb•in)

Wire cutter –

Loading...

Loading...