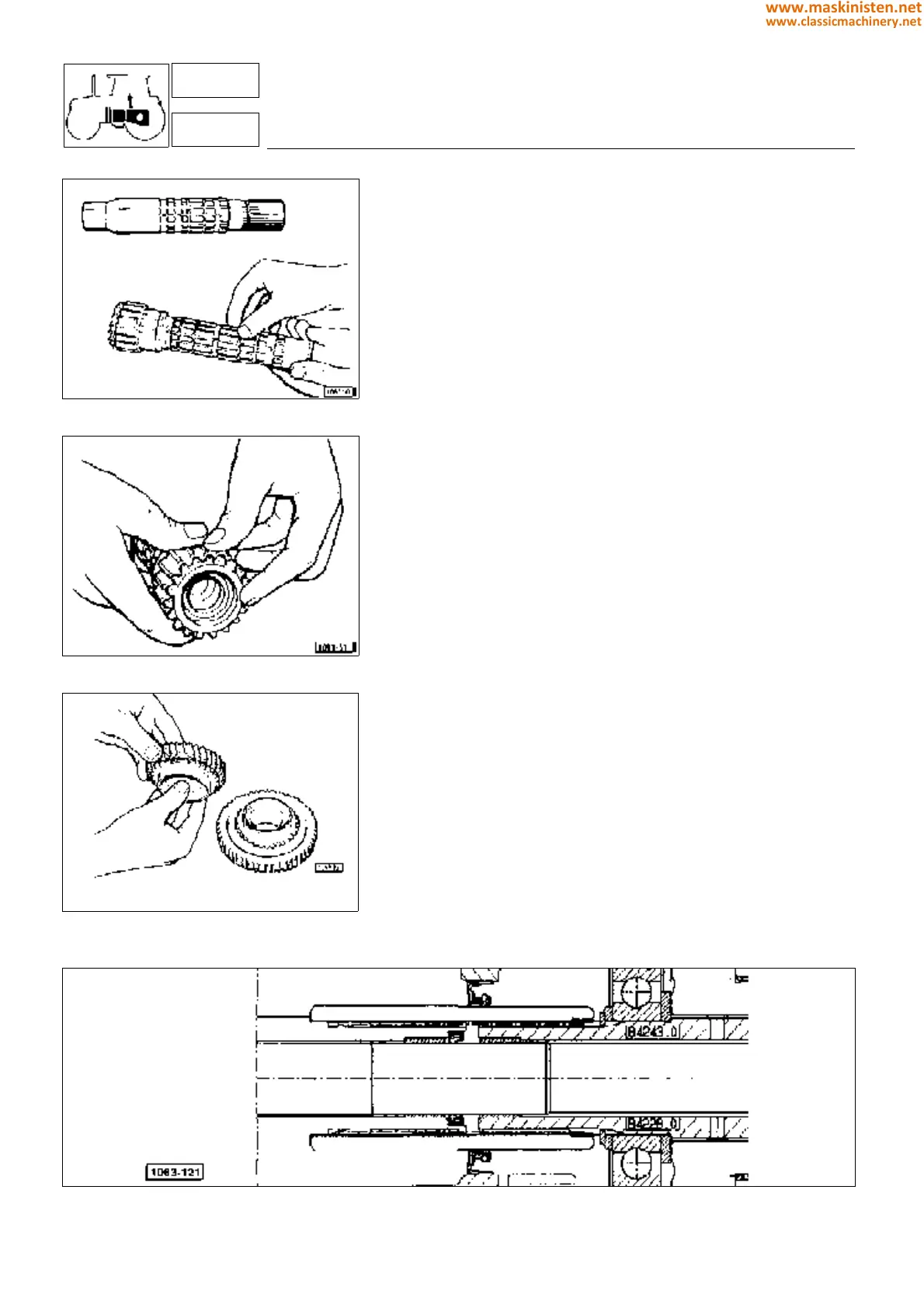

Fig. 24 - Checking the gearbox shafts removed.

Fig. 25 - Checking bushing for wear.

Fig. 26 - Checking gear teeth for wear.

Examining parts removed

Gearbox case

Gearbox case should show no cracks, bearing seats must not be worn

or damaged.

If seriuos damage or excessive wear is occured replace the parts con-

cerned.

Whenever the gearbox is disassembled clean all sealing surfaces remo-

ving old adhesive and applying some new on all surfaces evenly when

reassembling.

Shafts

Examine shafts for excessive wear and shaft splines for pitting, these

should allow the gears to slide freely.

Gears

Examine gear teeth for wear or damage and make sure these work on

the whole contact surface.

Check also the gear-mounted bushings for seizing: if so replace them.

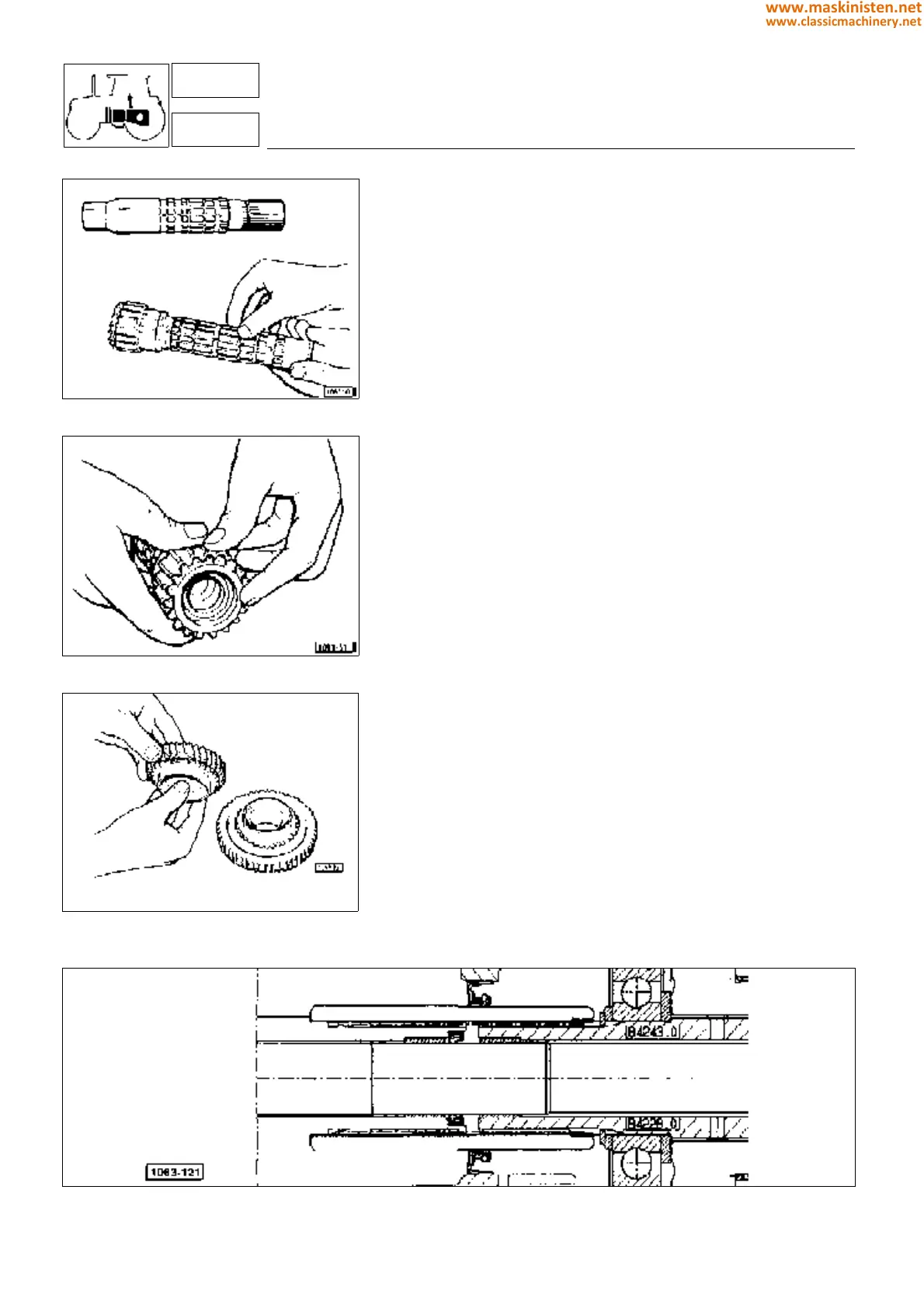

Synchronizers

Check the ring inside tapered portion for excessive wear or damage and

be sure the gear part being frictioned by the synchronizer does not show

signs of scoring which may prevent the gear from meshing correctly.

To check the synchronizer ring for wear, measure the distance from the

friction cone; reading should be 1.25

−

0.15

+

0.30

mm with a new synchronizer

or drop to zero when the ring is maximally worn.

Bearings

Bearings should be in perfect conditions without showing excessive radial

or end play.

Holding the bearings pressed by hand and making them simultaneously

turn in both directions of rotation a free sliding as well as no roughness

at all should be felt.

Examine the taper roller bearings for proper working conditions, these

should be neither worn nor overheated, replace as soon as poor working

efficiency is suspected, as an abnormal bearing operation may result in

either gear tooth seizure or noisy gearbox.

Warning: oil leakages from the clutch-disk-to-gearbox shaft or the engi-

ne-flywheel-to-P.T.O.-clutch shaft may be stopped when the assembly

procedure is performed with the utmost care and operating in such a way

that the splined parts are prevented from damaging the O-ring and also

providing a thorough cleaning of the parts prior to being installed.

transmission

primary shaft - secondary shaft - reduction gear unit

3

32-33-34

Fig. 27 - Shafts from clutch plate to gearbox.

150

www.maskinisten.net

www.classicmachinery.net

Loading...

Loading...