Inspections and checks

Clean bearings and the other parts carefully, then dry using

compressed air. Carefully examine the bearings turning them

slowly, if the bearing is sound no vibrations, noise nor slight

jam-ups shall be felt.

Carefully examine bearing race and rolling member conditions

ensuring no scoring, marking, grinding signs due to foreign matter

abrasion are noticed, otherwise replace the bearing.

WARNING: Should a bearing be no more serviceable, both the

internal and the external bearings must be replaced.

Make sure the wheel shaft has suffered no damage and threading

is whole, replace if required.

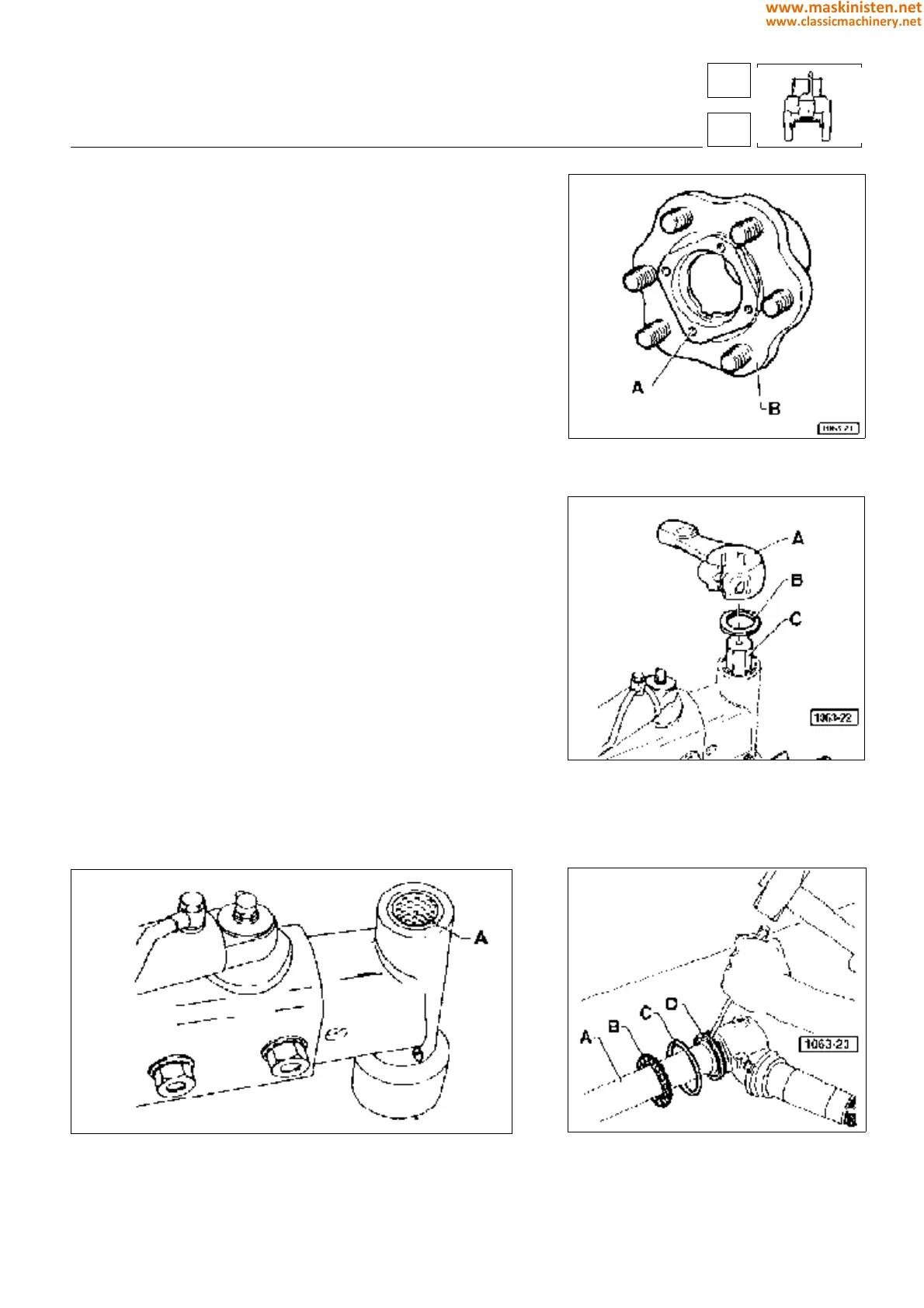

Ascertain clearance hole A permitting the external cover to be

fixed is not obstructed by foreign matters, if so remove any

clogging to allow hub B to be properly lubricated.

Wash any components carefully and dry with compressed air.

Be sure no signs of oxidation are visible on the wheel shaft, if so

remove with very fine abrasive paper.

Check the shaft for either warp or damage, if so replace the shaft.

Carefully inspect the axial bearing making sure no grinding, scor-

ing or marking are evident neither on the rolling members nor on

the bearing races, otherwise replace the worn parts.

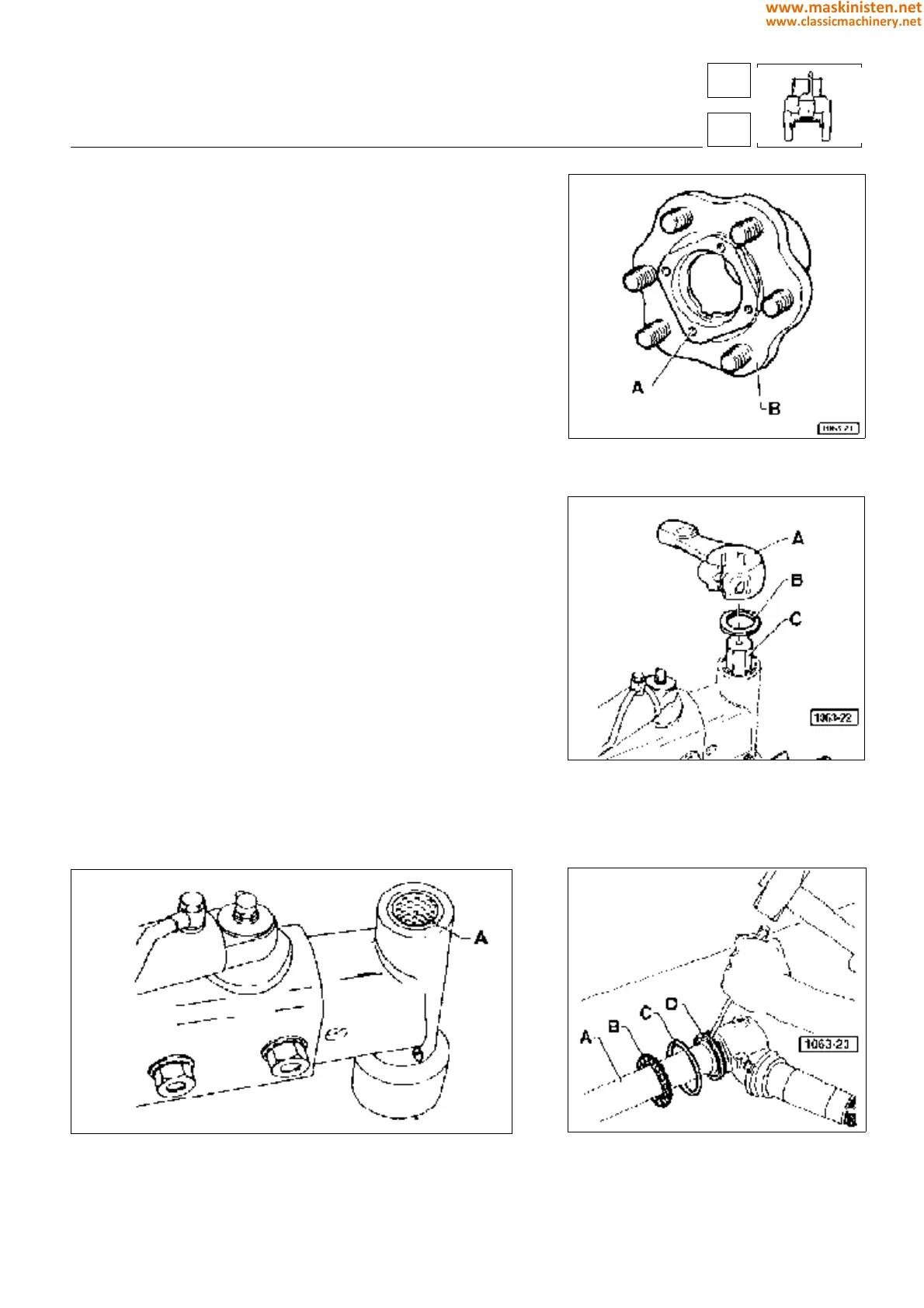

Check side axle upper and lower bushes B for wear, ascertaining

they still show evidence of the purpose-made indentations, other-

wise replace.

Fig. 24 - Wheel pivot bushes.

A - Clearance hole

Fig. 21 - Wheel hub lubricating hole.

A - Clearance hole

B - Wheel hub

Fig. 22 - Removing the steering lever.

A - External steering lever

B - Gasket

C - Wheel shaft

Fig. 23 - Removing the wheel pivot axial bearing.

A - Wheel shaft

B - Axial bearing

C - O-ring

D - Axial bearing race

drive axles - axles

2-W.D. extendible axle

42

4

193

www.maskinisten.net

www.classicmachinery.net

Loading...

Loading...