Internal adjustment of mechanical type differential

lock (fig 22)

(For adjustment of the external control linkage, see the "controls"

chapter).

1 - Assemble the components, locating all shims A on the side of

the circlip B; the overall thickness of the shims must be such that

clearance at the spacer C is between 0 and 0.05 mm.

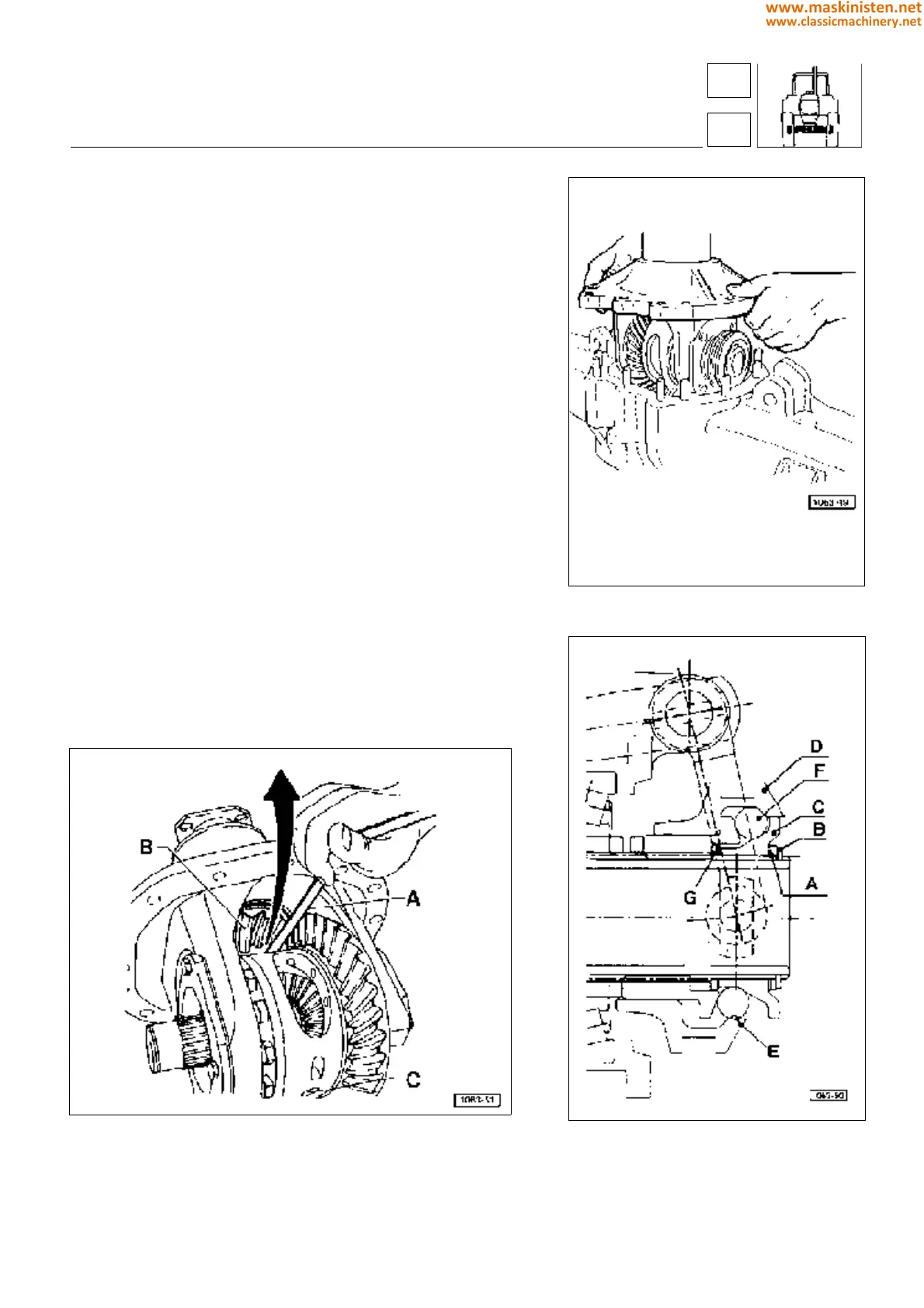

2 - Move the sleeve D and check that the flat surface E engages

the ball F at the position indicated in fig 22.

3 - If this is not the case, remove the circlip B, and transfer a pack

of shims 0.20 mm thick to the other side of the spacer C, in position

G.

Complete the assembly and check that the condition of point 2 is

satisfied; if not, repeat the procedureadjusting the mechanical-

type differential lock internally

Installing the differential assembly into the drive

axle

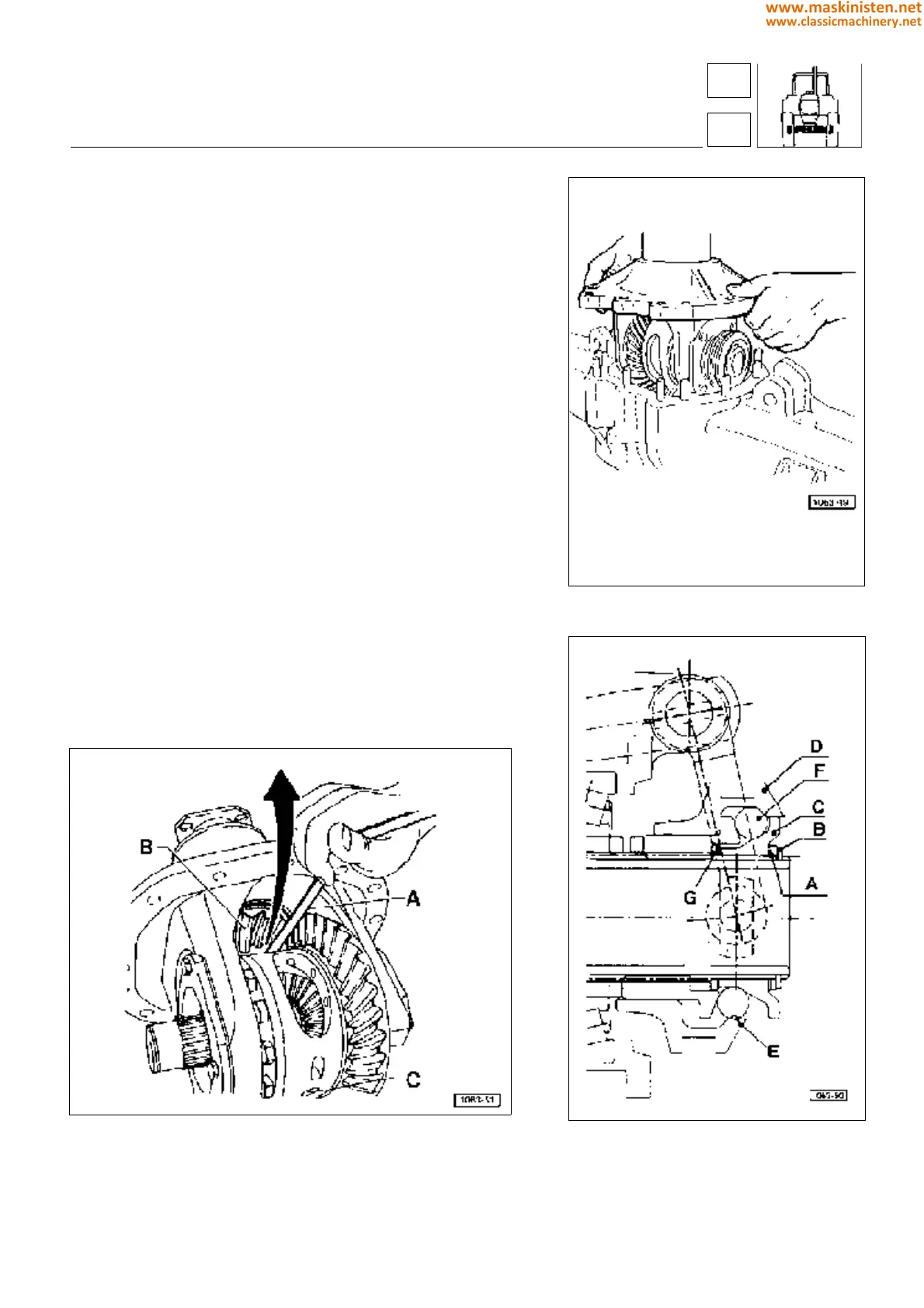

Swivel the assembly so that the differential lock sleeve is brought

in the same side as the internal control lever. The sleeve should

be moved outwards to enable the lever pad to be housed inside

the groove. After positioning the differential into the drive axle,

check the differential lock for proper engagement operating the

control lever and rotating the bevel pinion by hand.

Fig. 23 - Checking the difference between the bevel pinion head and

the differential housing ground surface.

A - Thickness gauge

B - Bevel pinion head

C - Differential planetary carrying pin

Fig. 21 - Swivelling the differential assembly in

the drive axle.

Fig. 22 - Differential lock adjusting references.

drive axles - axles

4-W.D. front axle

43

4

205

www.maskinisten.net

www.classicmachinery.net

Loading...

Loading...