Main bearings

engine

crankshaft

Ø machining Ø max. wear

— A main journal diameter mm 70.000

− 0.040

− 0.020

69.900

— 1st grinding mm 69.750

− 0.040

− 0.020

69.650

— 2nd grinding mm 69.500

− 0.040

− 0.020

69.400

— max. journal taper allowed mm 0.020 0.050

— max. main journal ovality allowed mm 0.005 0.050

— max. journal boring diameter mm 74

− 0.030

0

— B big end journal diameter mm 63.500

− 0.020

0

63.400

— 1st grinding mm 63.250

− 0.020

0

63.150

— 2nd grinding mm 63.000

− 0.020

0

62.900

— big end journal cilindricity mm 0.020 0.050

— big end journal out-off-roudness mm 0.005 0.050

— C main bearing inside diameter mm 70.000

+ 0.068

+ 0.018

70.130

— 1st undersize mm 69.750

+ 0.068

+ 0.018

69.880

— 2nd undersize mm 69.500

+ 0.068

+ 0.018

69.650

— crankshaft end play mm 0.105÷0.300 0.500

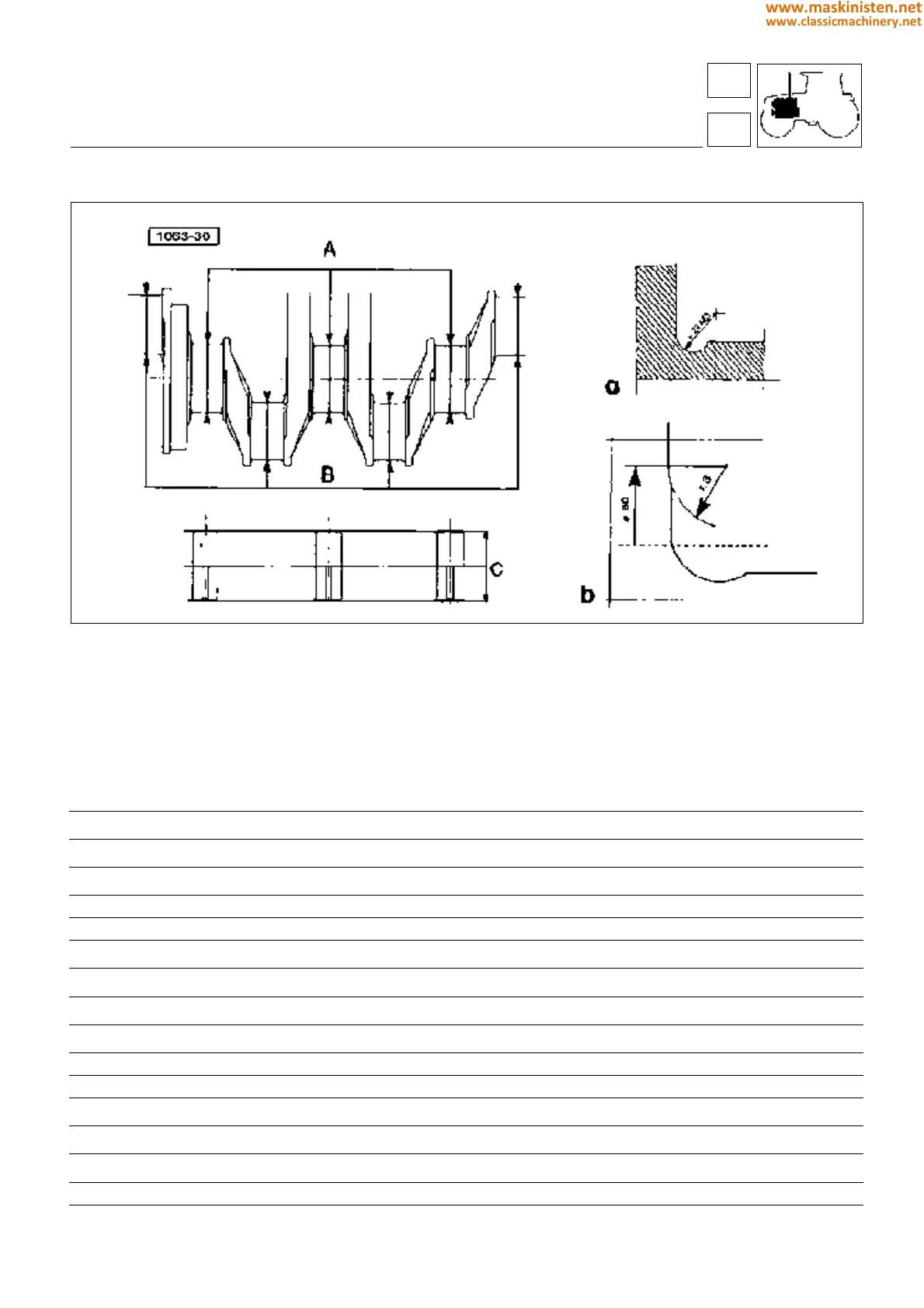

Fig. 9 - Crankshaft and main bearing dimensions.

a crankshaft main journal and big end journal machining.

b crankshaft tail journal machining.

c main bearing inside diameter

12

1

29

www.maskinisten.net

www.classicmachinery.net

Loading...

Loading...