The engine governor receives the speed signal in form of electric signal from a pick-up facing the engine flywheel ring

gear and controls the actuator installed on engine by an electronic control unit.

The control unit is fully digital type and contains the mode of operation defined for each engine model in form of

permanent storage programs (EPROM).

Communications towards the control unit may be entered by an EXTERNAL PROGRAMMER equipped with specific

functions enabling certain parameters to be diagnosed and set

.

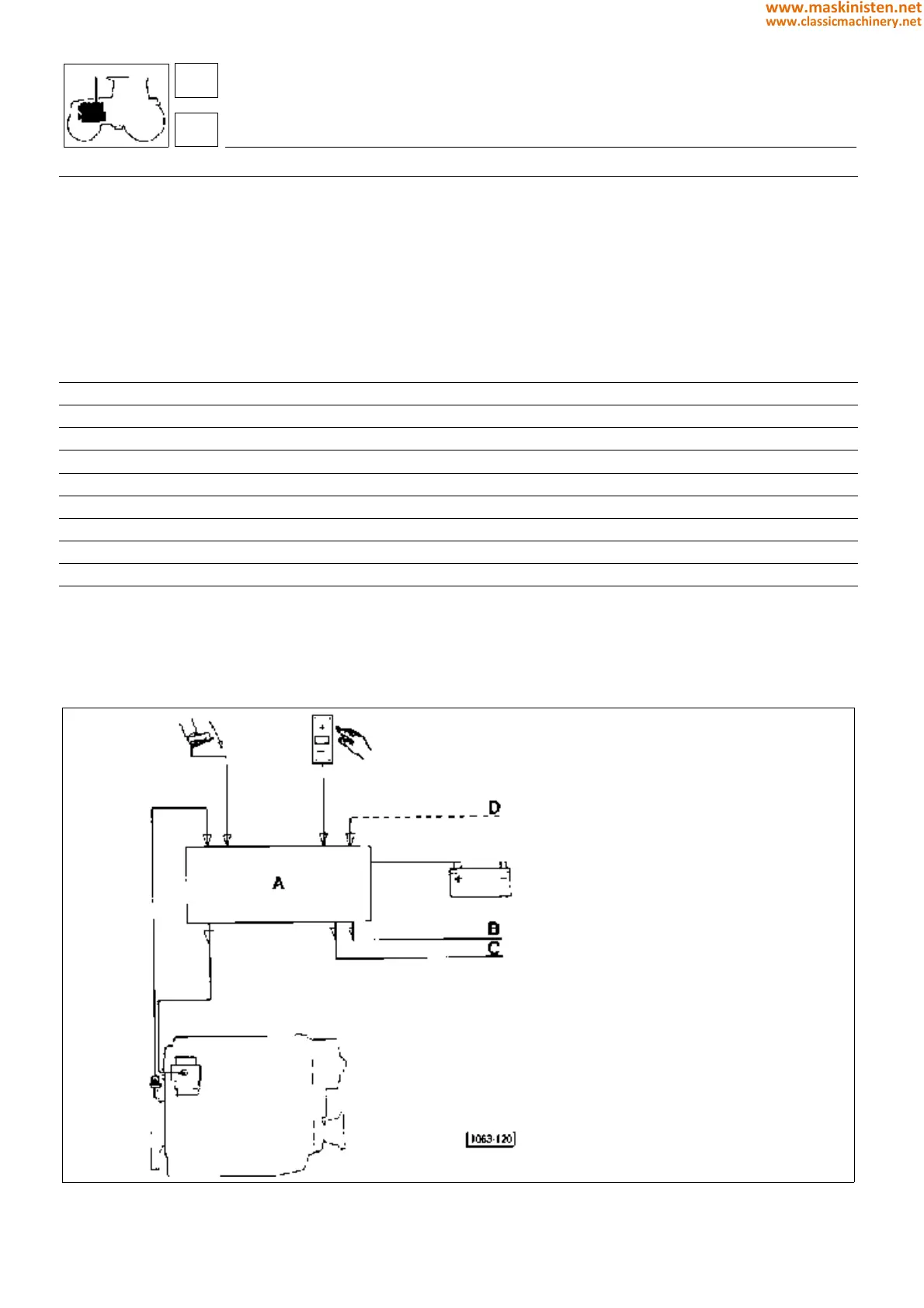

Fig. 25 - Configuration of the electronic engine control system.

A - ELECTRONIC CONTROL UNIT

B - DIAGNOSTICS

C - SPEED CONSUMPTION

D - PROGRAMMER

ELECTRONIC ENGINE GOVERNOR

General information

The electronic engine speed governor consisting of a REG2MK microprocessor permits an accurate and stable engine

r.p.m. control to be obtained. The system includes an ELECTRIC ACTUATOR, a MAGNETIC PICK-UP acting as a

speed recorder, a PUSH-BUTTON PANEL with LED indication (hand throttle) and a POTENTIOMETER located on the

accelerator pedal.

Specifications

power supply 8 to 15 V DC

card electrical input 35mA + actuator current

maximum actuator current output 6 A

PICK-UP input 5 to 30 Vrms

operating temperature range -40 to +85 °C

humidity rate 0 to 100% non condensed

control isochronous or with statism

speed range 600 to 2700 r.p.m.

overspeed set at 3500 r.p.m.

reliability 70 °C

engine

fuel system

16

1

64

www.maskinisten.net

www.classicmachinery.net

Loading...

Loading...