The installation of single-cylinder injection pumps besides ensur-

ing an even load distribution on the camshaft has permitted two

bearings per camshaft journal to be mounted in the engine block,

thus minimizing camshaft flexure.

A bimetallic bushing is inserted in each bearing to ensure very

smooth camshaft operation. This can be replaced when wear

exceeds the limits specified above.

All these features guarantee precise cam movement thus provid-

ing smooth timing system operation and regular fuel supply as

well.

The camshaft is held in position by a forked plate fitted on engine

front side.

For 1000.4-A engines

The engine oil pump and engine governor driving gear is mounted

at the rear camshaft end.

Prior to installing camshaft, the engine block should be turned

upside down and the tappets inserted in the related seats in the

block after having been properly lubricated with oil.

Make sure the tappets slide in their seats freely.

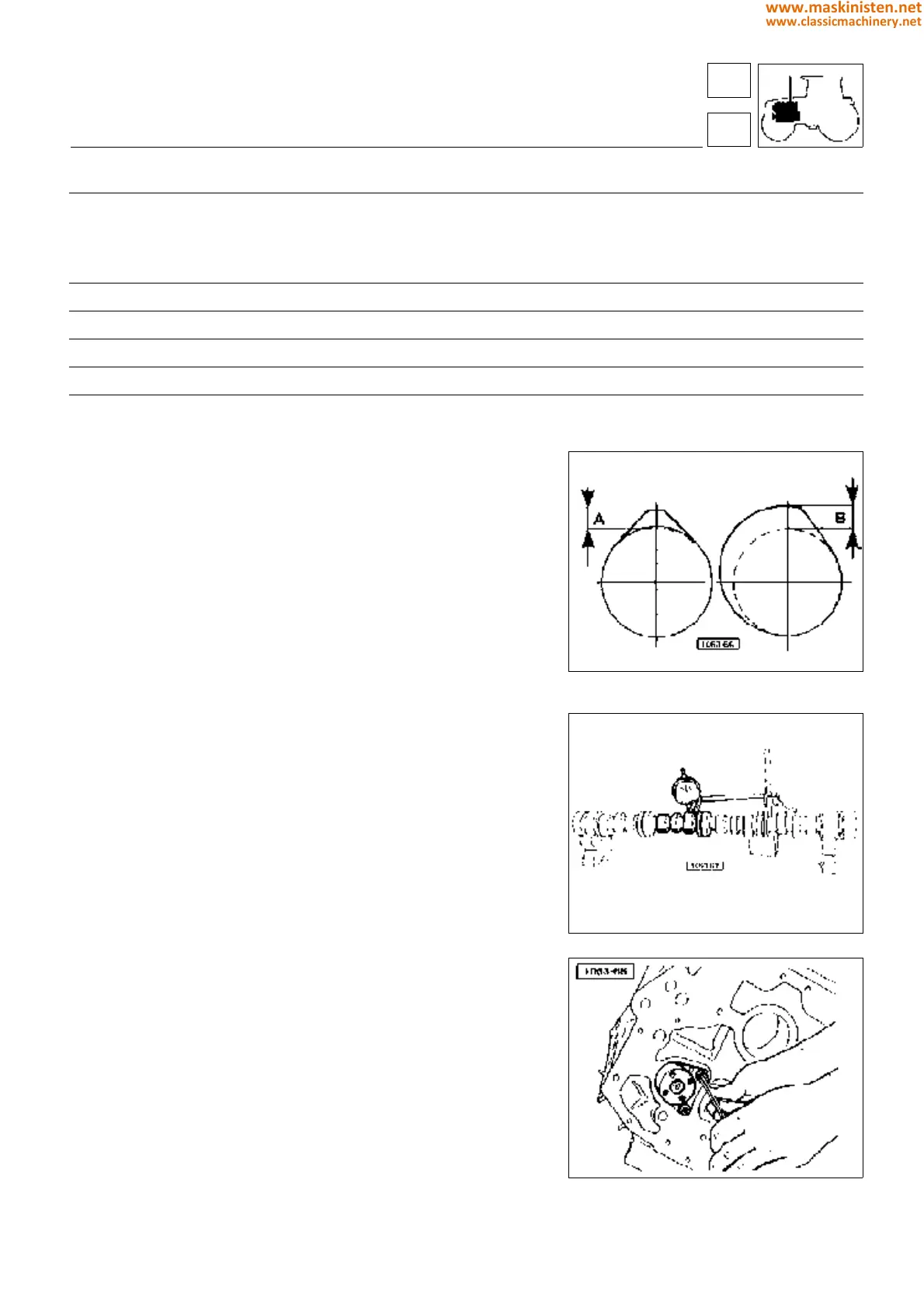

Fig. 1 - Timing system cams:

A - Valve cam; B - Injection cam.

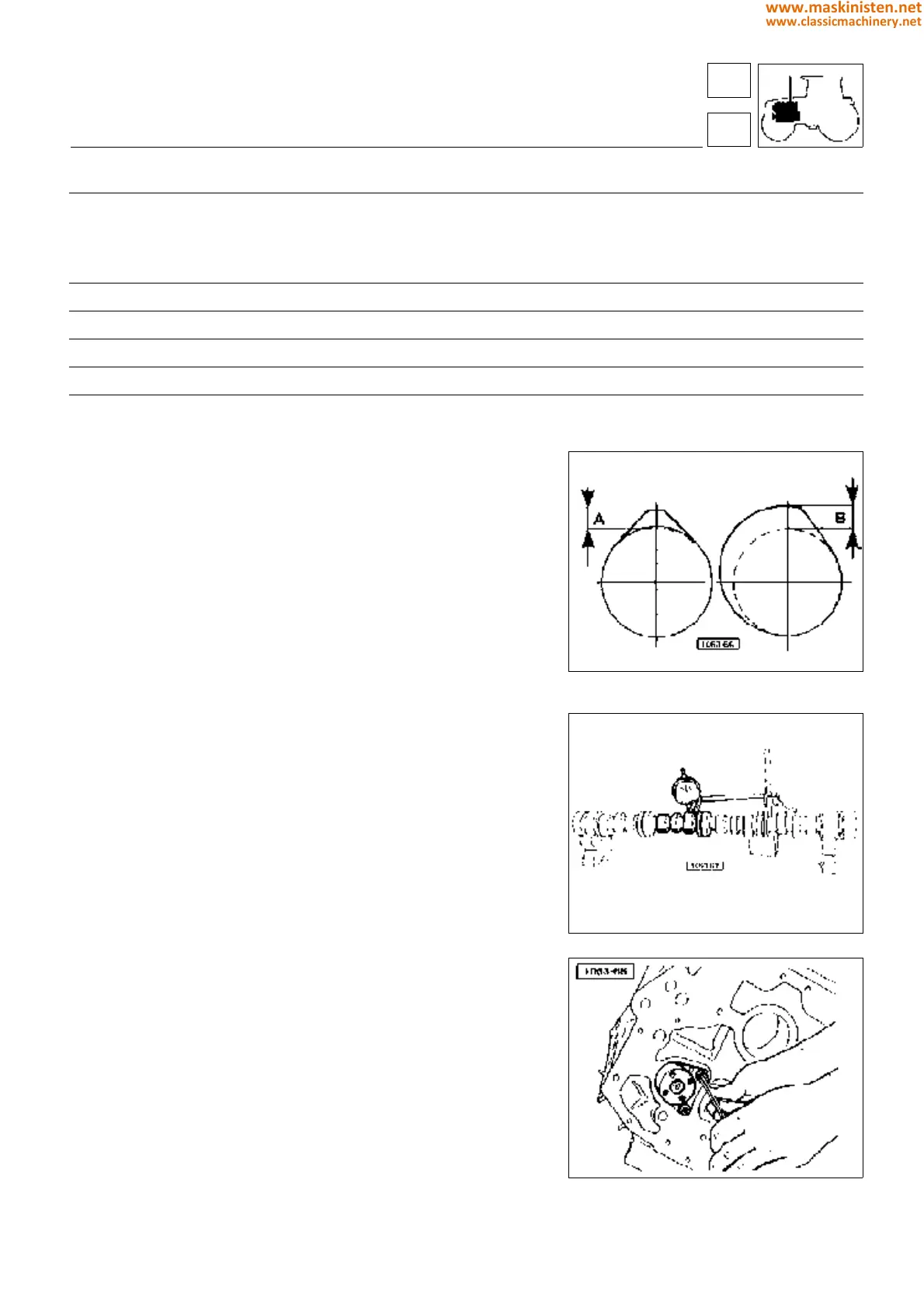

Fig. 2 - Checking cam wear.

Fig. 3 - Camshaft fixing forked plate.

engine

camshaft

Ø machining Ø max. wear

Camshaft cam lift

intake cam mm 6,86

− 0,05

+ 0,05

6.30

exhaust cam mm 6,71

− 0.05

+ 0,05

6,20

injection cam mm 8

− 0,05

+ 0,05

7.50

Camshaft journal diameter mm 55

− 0,030

0

54.950

Camshaft bushing diameter mm 55

− 0,090

+ 0,060

55.180

Idler gear bushing diameter mm 40

− 0,064

+ 0,025

40.125

Idler gear pin diameter mm 40

− 0,025

0

39.950

13

1

43

www.maskinisten.net

www.classicmachinery.net

Loading...

Loading...