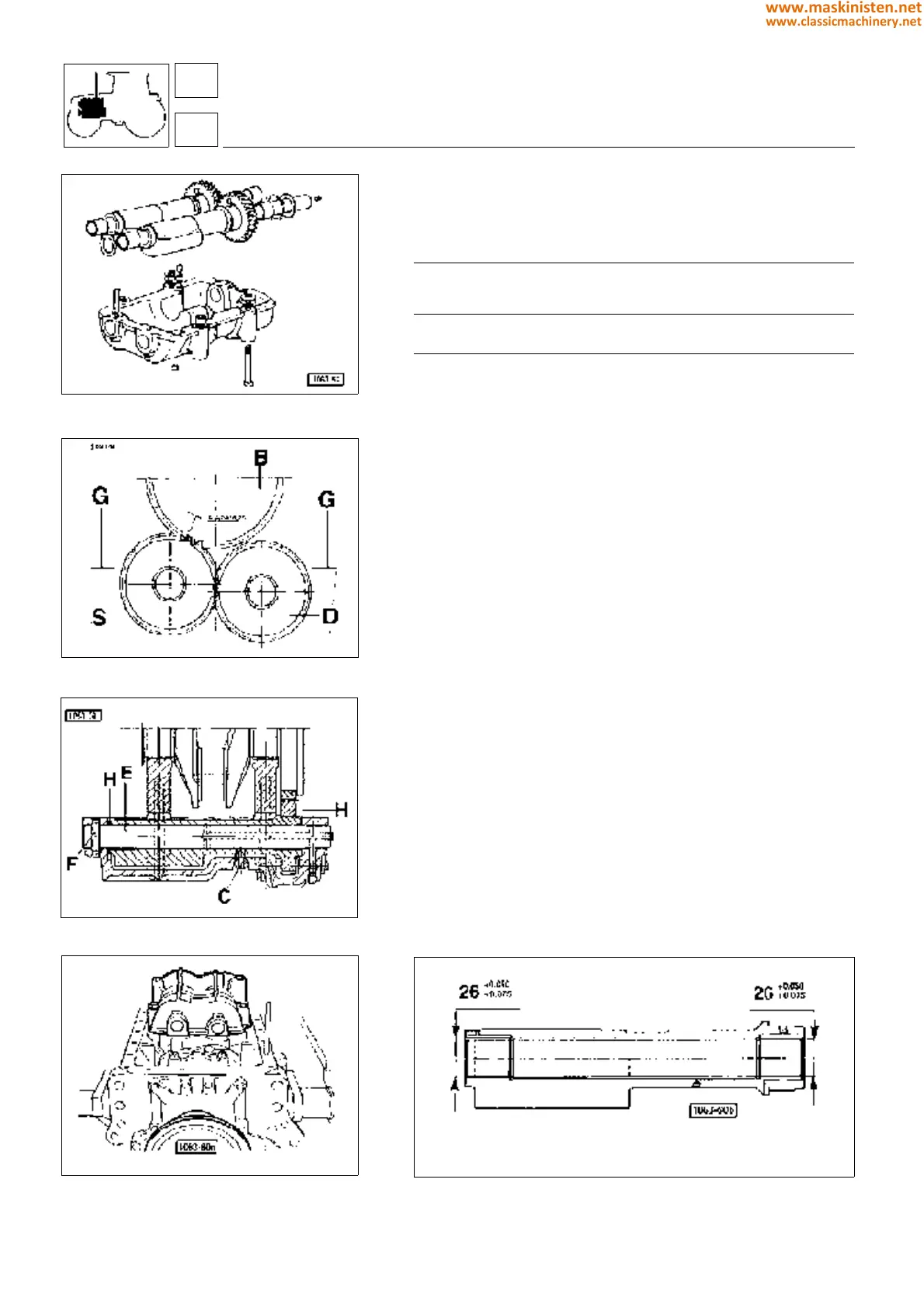

Fig. 37 - Counterweight assembly components.

Fig. 38 - Counterweight assembly.

Fig. 39 - Counterweight assembly cutaway-view.

Fig. 40 - Engine-installed counterweights.

Counterweights for 4-cylinder engines

Specifications

counterweight end play mm 0.10.43

backlash allowance

between counterweight and

crankshaft crown wheel teeth mm 0.200.25

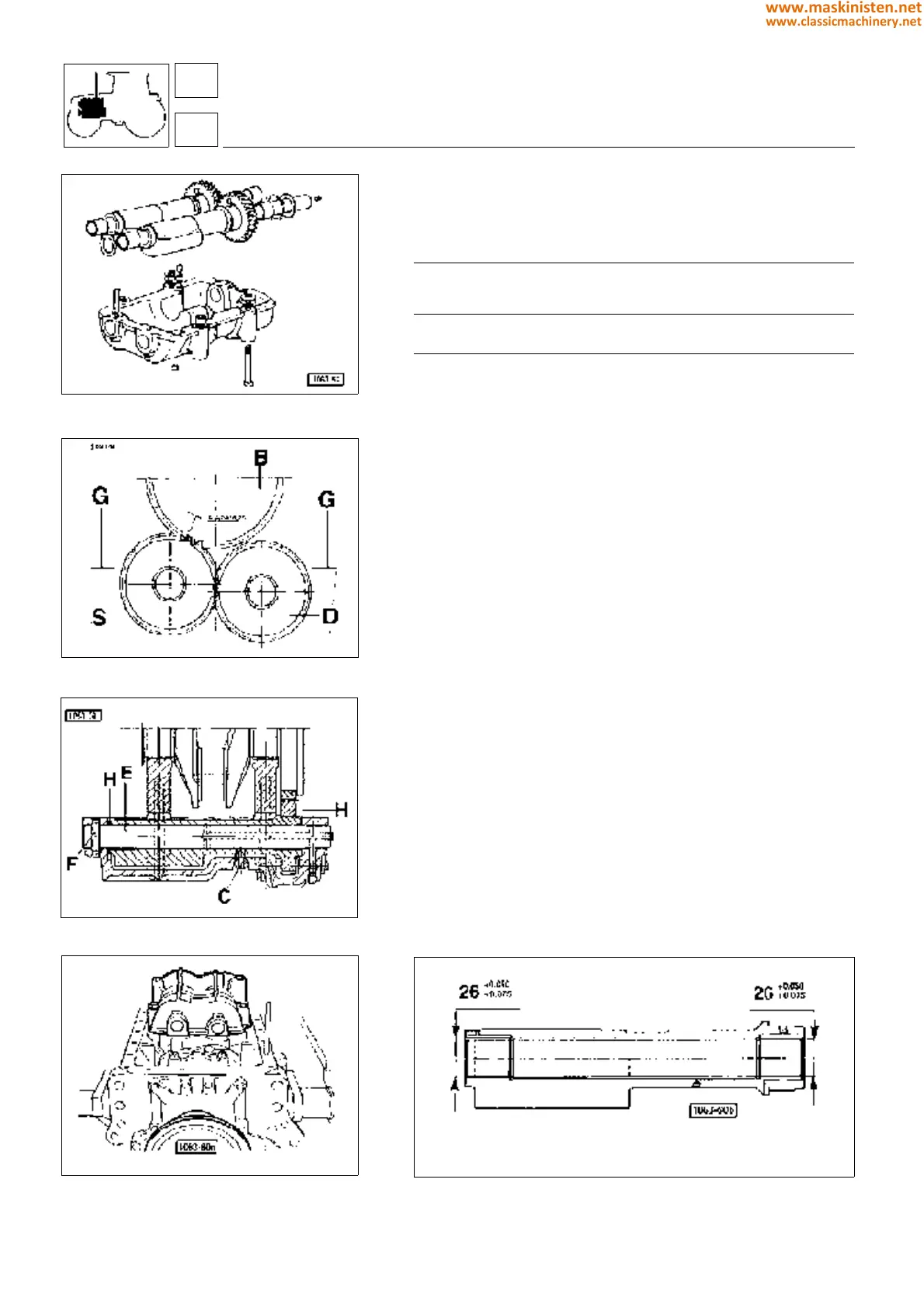

bushing inside diameter mm 26

+ 0.075

+ 0.050

max. wear mm 26.150

Checking counterweights

Check counterweight bushing inside surface conditions. Ensure

the inside diameter is not above specifications; otherwise replace

bushings.

With bushing installed perform boring according to specifications

given in the table above.

Installing and adjusting counterweights

Position the weight marked with S in the related support seat, then

place weight D too, so that the engraved teeth coincide as shown

in figure.

Fit gudgeons E and insert spacer washers H.

Be sure the counterweight end play is 0.1 to 0.43 mm. Complete

installation by fixing gudgeons through special pins F and the

weights with securing screw C.

Apply the support and weight assembly underneath the cylinder

block so as the engraved counterweight S tooth engages between

the two engraved teeth of crankshaft crown wheel B. Then fit a

number of shims G until a 0.20 to 0.25 mm backlash between

crankshaft crown wheel and weight S teeth is obtained.

Remove screw C and finally tighten the weight support securing

screws to cylinder block also applying some Loctite 242.

Fig. 41 - Installed counterwight bushings.

engine

crankshaft

SILVER 80 - 90 - 100.4

12

1

40

www.maskinisten.net

www.classicmachinery.net

Loading...

Loading...