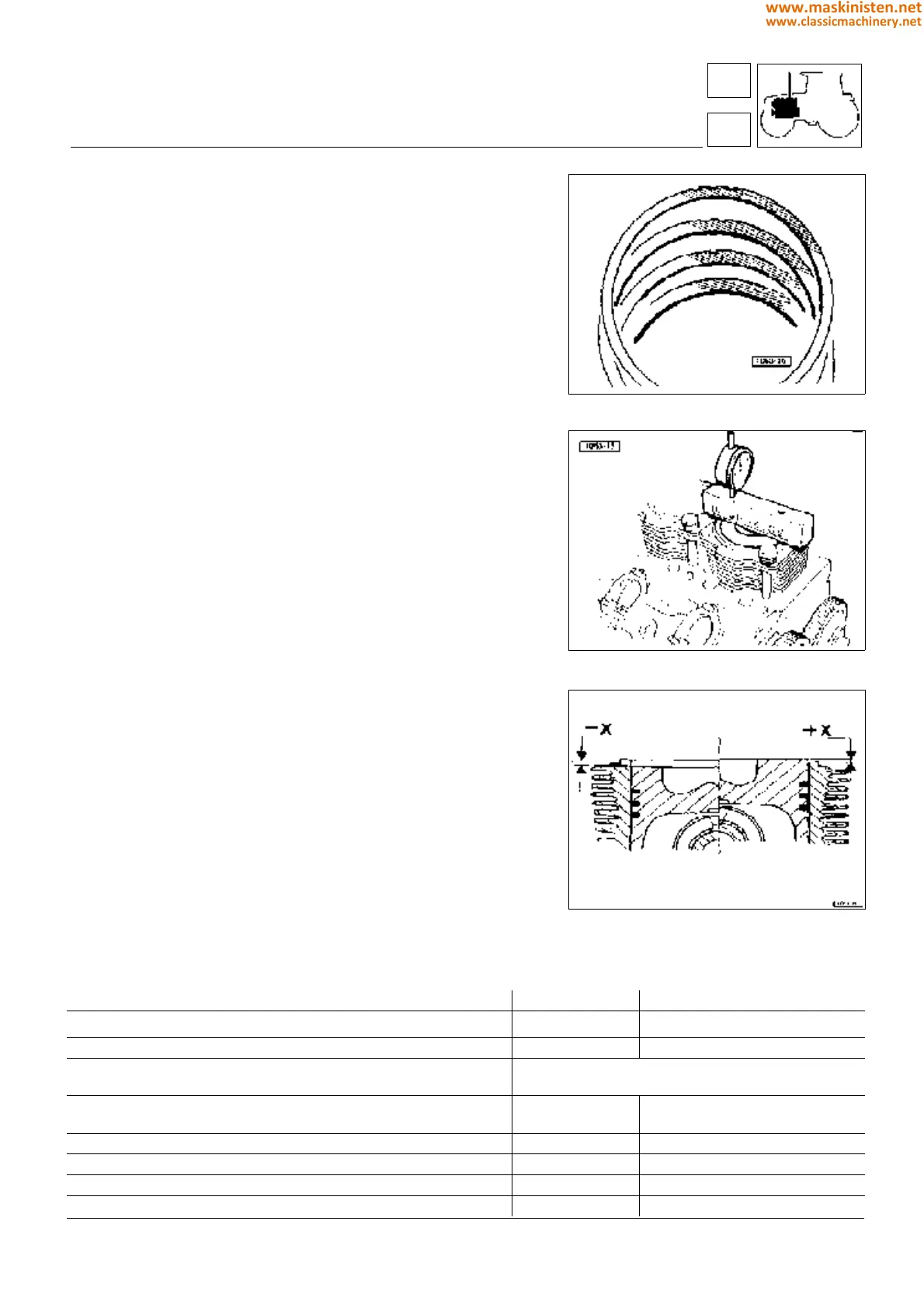

Using the following equipment:

5.9030.627.0 centesimal dial gauge

5.9030.433.0 dial gauge base

5.9030.631.4/10 cylinder pressing tool

ensure the piston crown at T.D.C. recesses from the head gasket

bearing surface (see Fig. 6).

Move the dial gauge base until the gauge feeler lies on the cylinder

surface and take reading from the dial.

Reset the dial gauge.

Place the base so that the gauge feeler lies on the piston head at

T.D.C. and take reading.

Choose the gasket to be fitted according to reading taken (also

refer to item D in the table here below).

Fig. 5 - Cylinder head gasket.

Fig. 6 - Checking piston position at T.D.C.

Fig. 7 - Determining the engine cylinder head

gasket thickness.

engine

cylinders

Ø machining Ø max wear

A inside diameter measured half-way along the cylinder mm

105.000

+ 0,022

− 0

105.100

B roundness errormm 0.020 0.080

C piston recess from the head gasket

bearing face on cylinder mm

0.30÷0.40

D determination of head gasket thickness x

reading

gasket thickness

gasket ref. code 0.085.1450.0 mm -0.562 ÷ -0.300 0.5 without locating notches

gasket ref. code 0.085.1451.0 mm -0.290 ÷ -0.110 0.7 with 1 locating notch

gasket ref. code 0.085.1453.0 mm -0.100 ÷ +0.020 0.8 with 3 locating notches

gasket ref. code 0.085.1452.0 mm +0.030 ÷ +0.178 1 with 2 locating notches

12

1

27

www.maskinisten.net

www.classicmachinery.net

Loading...

Loading...