Cleaning crankshaft and cylinder block internal

passages

Cleaning of the lubricating oil passage should be made after all crankshaft

and cylinder block overhauling operations have been accomplished.

This cleaning can be carried out by using Diesel fuel or compressed air

blasted into the passages.

Checking crankshaft end play (Fig. 16).

This check is performed with a magnetic base comparator operating as

follows:

–place the magnetic base together with the comparator onto the crank-

case and then make the comparator feeler contact one of the crankshaft

ends.

–use a lever to move the crankshaft axially towards the comparator side

until the comparator hand stops moving.

–reset the comparator and push the crankshaft with the lever towards the

opposite side and then take the end play reading from the comparator

dial.

This reading should be 0.10 to 0.27 mm; if higher than specified, some

spacing half-rings with 0.10 to 0.20 mm oversize with respect to the

nominal thickness shall be fitted. These half-rings are regularly supplied

as spare parts.

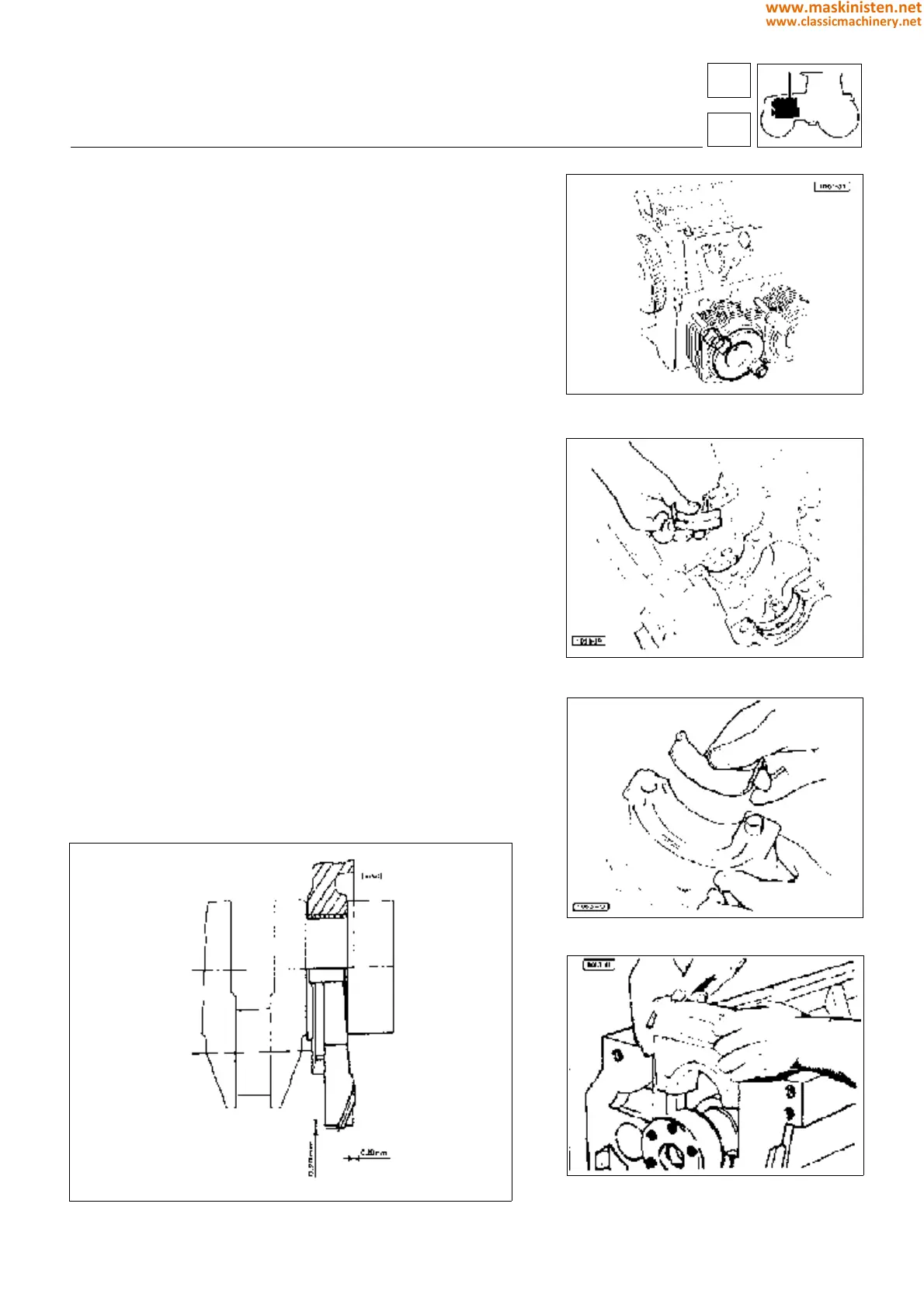

Triangular-section gaskets should protrude as shown in figure 17.

In its rear portion the crankshaft is provided with a 3x30° chamfer. In

addition the surface contacting the sealing ring has undergone a harde-

ning process.

The oil seal must be fitted using tool 5.9030.628.0.

Fig. 17 - Main bearing cap gasket installation.

Fig. 18 - Special fixture for piston positioning

during crankshaft installation.

Fig. 19 - Mounting one holed main bearing shell

into the cylinder block forging.

Fig. 20 - Fitting the one main bearing shell into

the main bearing cap.

Fig. 21 - Installing the crankshaft main bearing

caps.

engine

crankshaft

12

1

33

www.maskinisten.net

www.classicmachinery.net

Loading...

Loading...