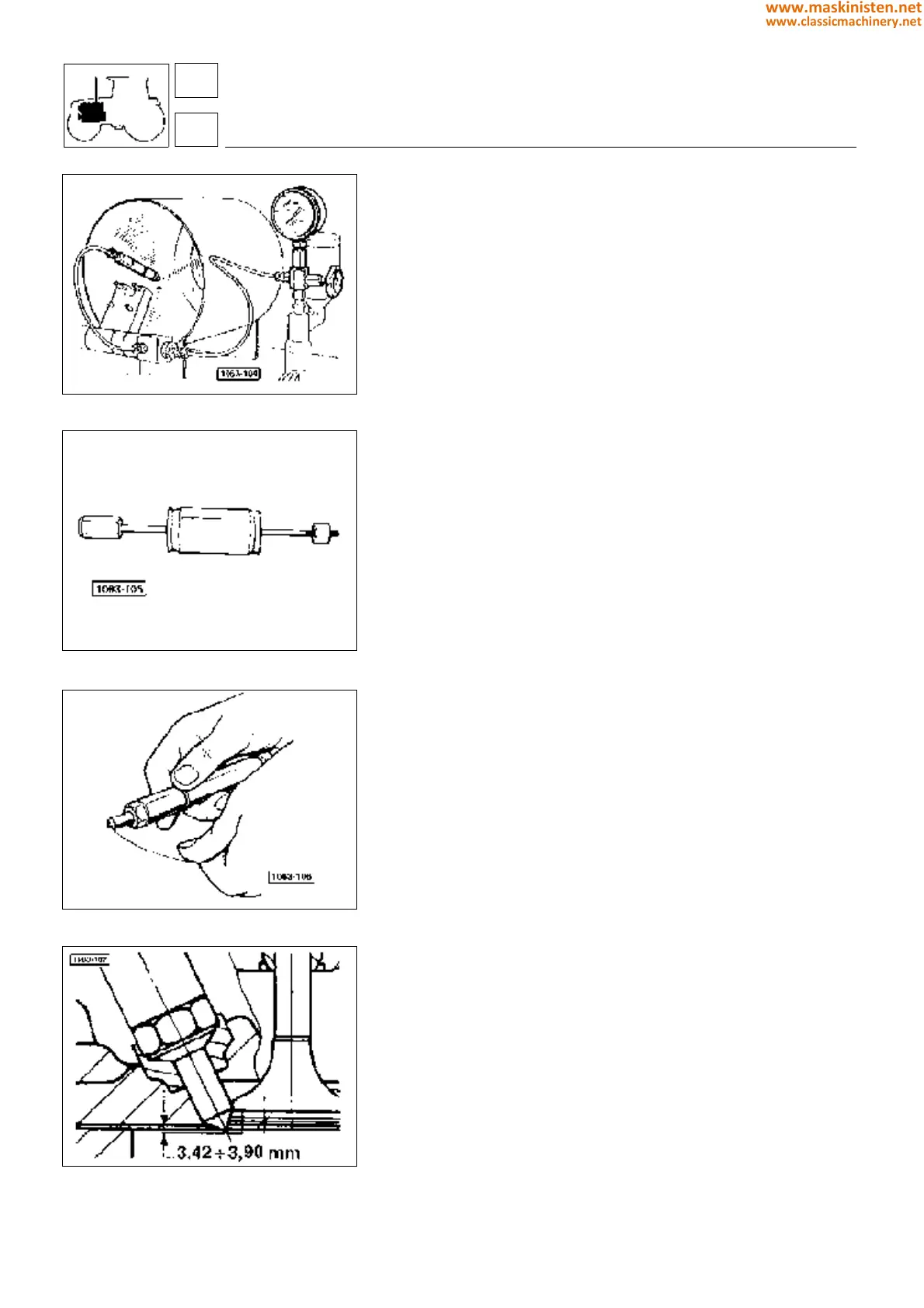

Fig. 4 - Checking injection nozzle spraying effi-

ciency.

Fig. 5 - No. 5.9030.618.4 tool used to remove

injection nozzle from seat.

Fig. 6 - Cleaning injection nozzle with a piano

wire.

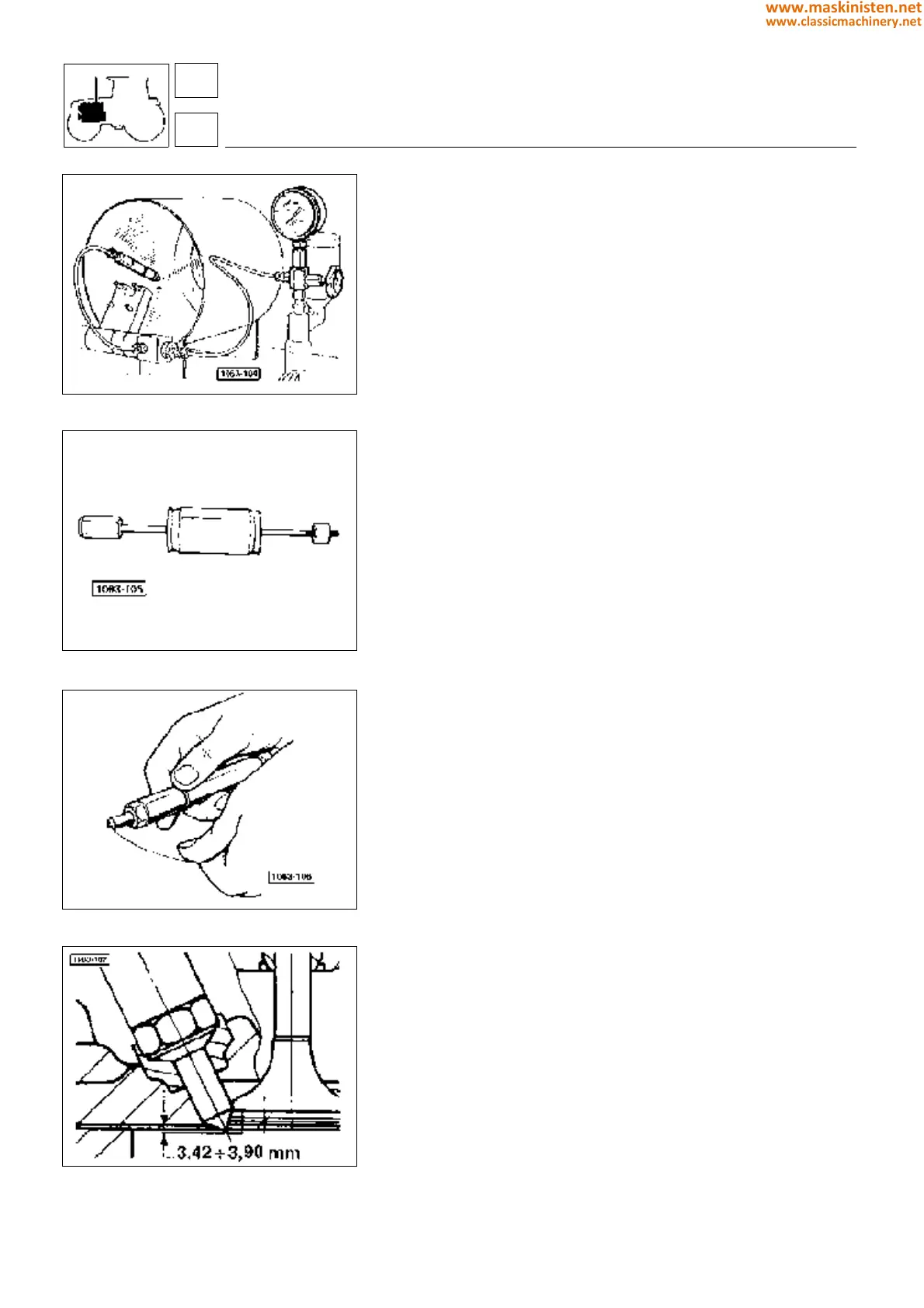

Fig. 7 - Injection nozzle projection from the cylin-

der head face.

Checking injection nozzle seat tightness

Checking the injection nozzle seat tightness is very important as

this permits to verify whether there is any fuel dripping from the

injection nozzle before the calibrating pressure is reached.

This test is carried out by operating the hand pump until a pressure

reading about 10% lower than the calibration pressure is attained.

Take care this pressure be maintained by oppotunely pressing on

the hand pump lever, so as to compensate the pressure drop

which otherwise would be caused by the fuel dripping between pin

and nozzle holder body.

Under these conditions the injection nozzle should never drip;

otherwise consult an injection pump specialist.

Checking injection nozzle spraying efficiency

Connect the injection nozzle to a pump and operate the pump lever

repeatedly so that the operating conditions may be reproduced.

Fuel must be sprayed from the nozzle holes in form of finely

atomized jets, which should all be equal in size. There should be

as many jets as there are holes in the injection nozzle.

Otherwise, clean the nozzles by removing first the residual carbon

deposits from the nozzle holes with a Ø 0.26 mm steel wire and

then clean them thoroughly with a Ø 0.28 mm wire, this having the

same diameter as the nozzle spraying holes.

Injection nozzle projection from the cylinder head

face plane

Make sure the injection nozzle projects 3.42 to 3.90 mm from the

cylinder head face plane.

engine

fuel system

16

1

54

www.maskinisten.net

www.classicmachinery.net

Loading...

Loading...