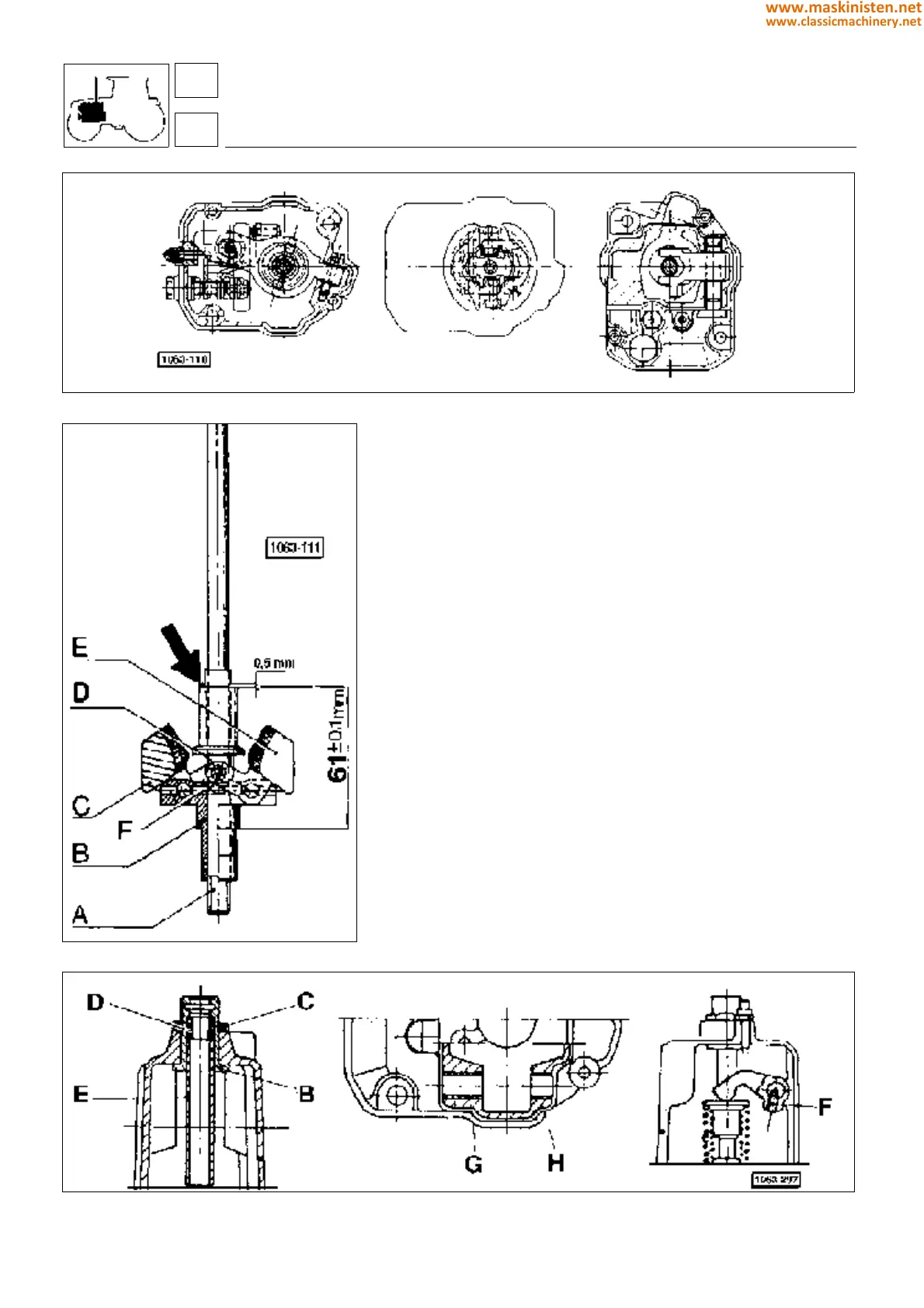

Fig. 11 - Installing weights on the governor shaft.

Mounting governor weights (Fig. 11)

Apply Loctite 601 to the crankshaft surface A in contact with

support B, then fit the support to the crankshaft, positioning the

two pieces to allow fitting of dowel F. Fit the weights C and E to

the support by means of plates D inserted in the groove of the

sliding sleeve.

Open weight C against the stop thereby holding the weight whose

plate rests on the coupling and releasing the other one, then move

the coupling against the locked plate. Be sure the dimension

reading is 61

±

0.1 mm, as shown in Fig. 11, otherwise add or

remove shims (ref. code 2.1589.160.0 and 2.1589.161.0) to/from

the position indicated by the arrow.

Installing governor assembly

Lower casing

Install the engine STOP control levers, both internal and external

ones, then insert the plate and related stop screws (see items a

in fig. 14).

Place bearing A (fig. 13) into the casing and fit levers B and C (fig.

13) along with the full assembly components (b fig. 14).

Warning: Before installing lever C be sure this has a 20 mm

portion showing absolutely no indentation (see figure 13).

Install the shaft and mounted weights securing to the bearing with

the special nut.

Install bearing D as well as the sliding coupling and fit the eccentric

screw E into the casing, paying attention the chiseling on the screw

head is in the upper position.

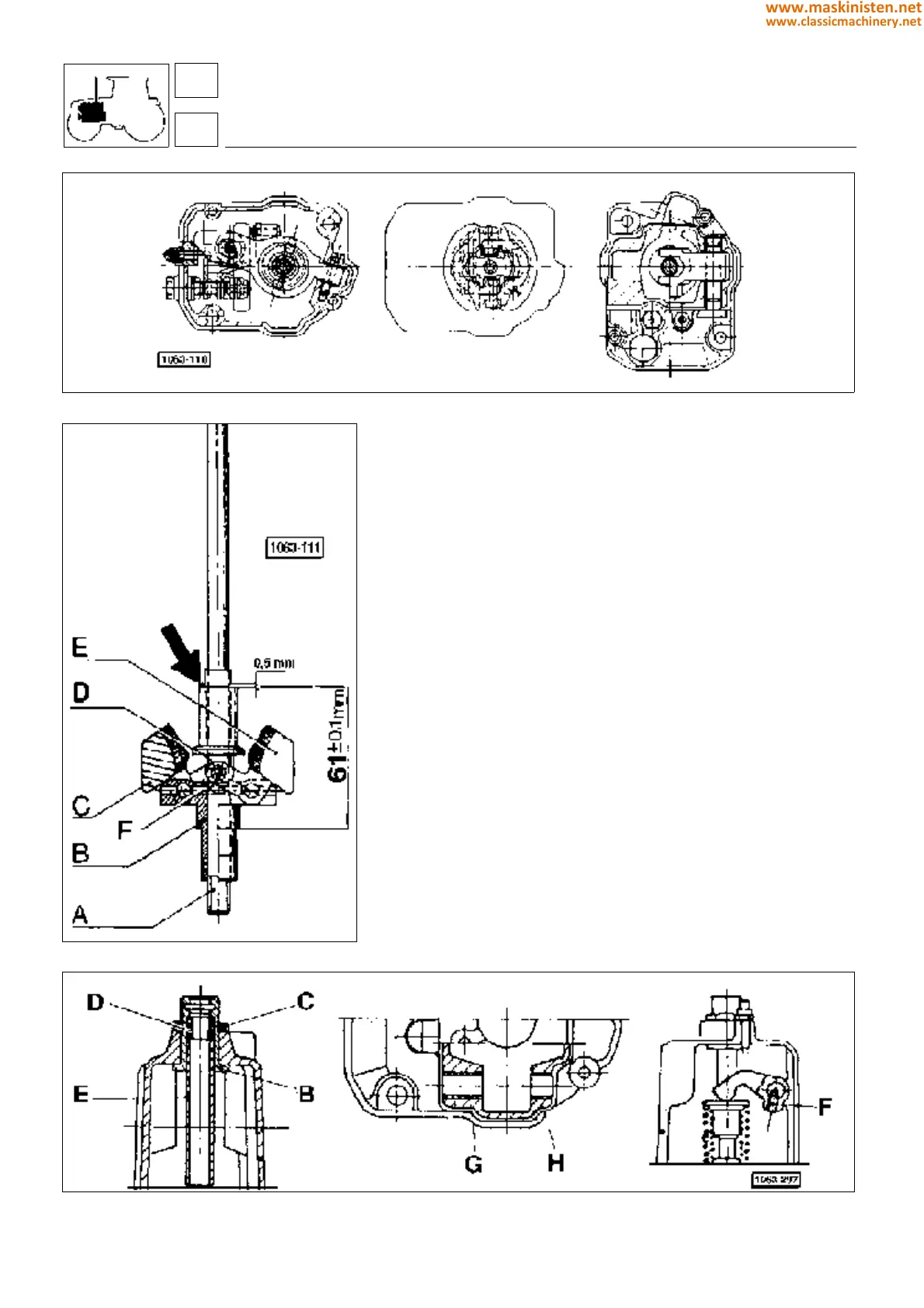

Fig. 10 - Engine governor assembly cross-section.

engine

fuel system

SILVER 80 - 90 - 100.4 - 100.6

Fig. 12 - Governor sealing points with LOCTITE.

16

1

56

www.maskinisten.net

www.classicmachinery.net

Loading...

Loading...