Installing and checking actuator

When installing the actuator take note of the following:

— the actuator lever should move the pump rod freely and without friction;

— a free rod must return in stop position;

— the actuator rod must be matched to the pump rod fork with a slight play.

WARNING:

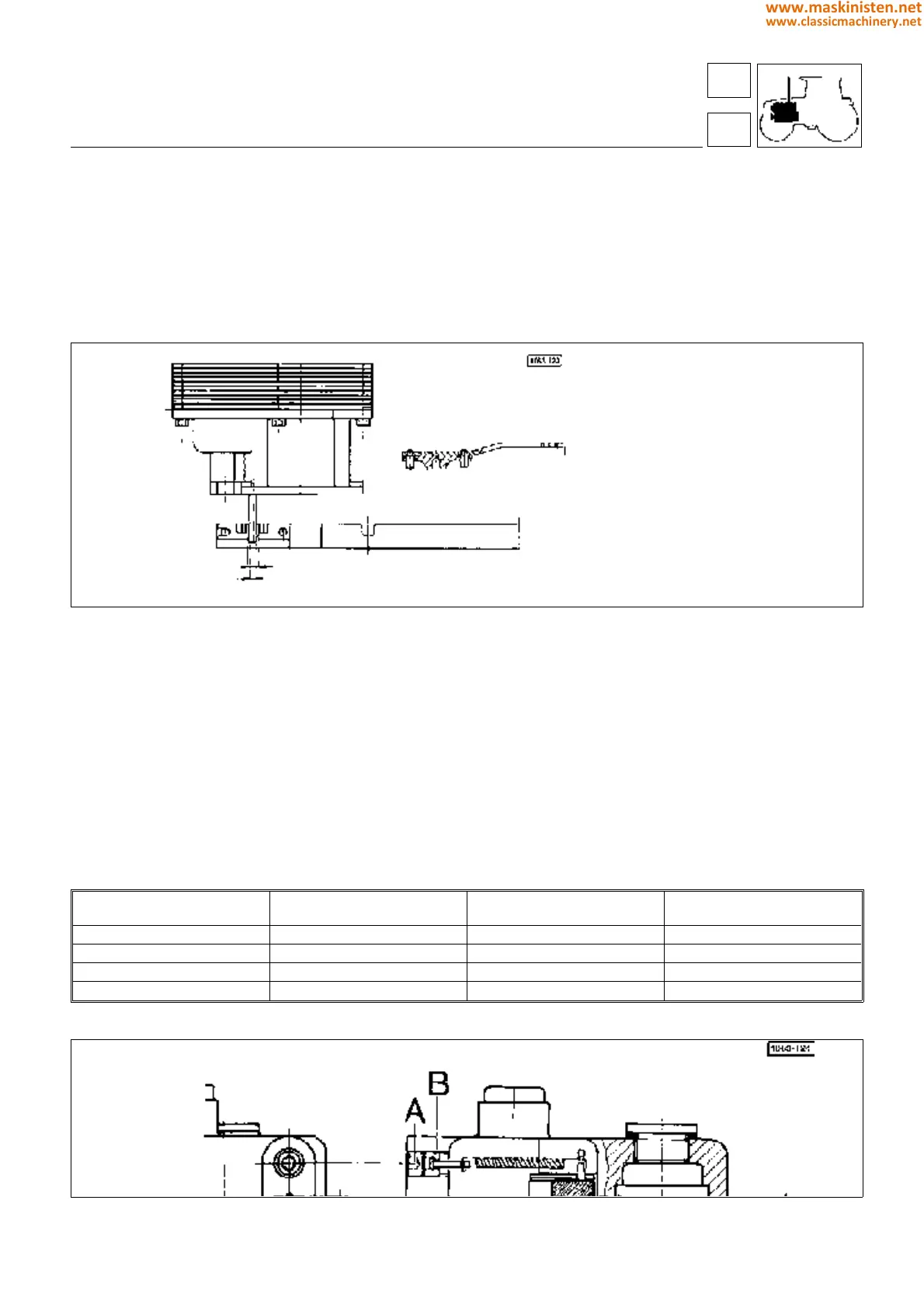

The actuator is provided with cover A (Fig. 28) to protect the access to the injection pump control rod stroke adjusting

device.

This cover is secured to the actuator by means of self-tapping rivet B (Fig. 28).

Fig. 30 - Positioning the injection pumps actuator and control rod clevis.

Calibrating the governor actuator

Calibrating the actuator is a most delicate operation.

This should be performed in case of external interventions including actuator replacement.

Operate as follows:

— Turn on the engine and run to 2000

±

100 r.p.m. using the hand throttle.

The engine should never be subjected to dragging loads, make sure the red LED on hand throttle control lever is

illuminated.

— Remove plug A (Fig. 31) to gain access to the actuator spring for spring load setting and loosen screw B (Fig. 31)

until first the engine r.p.m. droops and then the engine stops.

WARNING: locating this condition requires most accuracy and meticulous operating procedure and namely:

— locate approximately the point where the engine r.p.m. starts drooping;

— with engine stationary lock the screw B (Fig. 31) of a number of turns as shown in table below.

Fig. 31 - Setting the rpm control actuator.

Calibration on a specific test bench:

power supply 2A

±

0,01

rod stroke 11,5

+ 0,2

mm

TRACTOR TYPE ENGINE R.P.M. HP

ADJUSTING SCREW B

TIGTHENING TURN NO.

SILVER 80 2100 80 3,75

SILVER 90 2100 90 3,25

SILVER 100.4 2100 100.4 4,75

SILVER 100.6 2100 100.6 3

CAUTION: When fitting plug A operate so as any alteration of the adjusting screw B position may be prevented.

engine

fuel system

16

1

67

www.maskinisten.net

www.classicmachinery.net

Loading...

Loading...