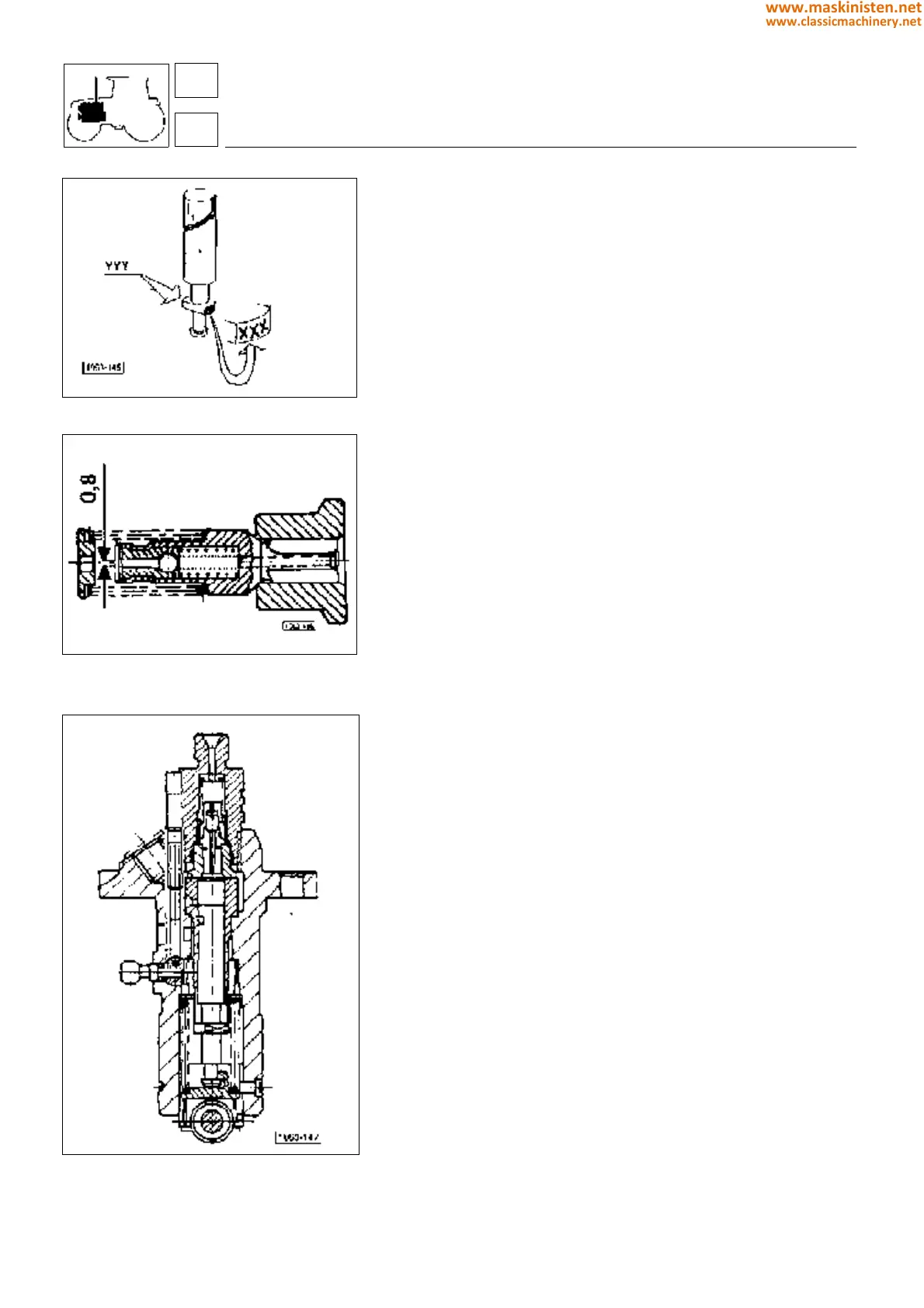

Fig. 11 - Injection pump plunger identification

marks.

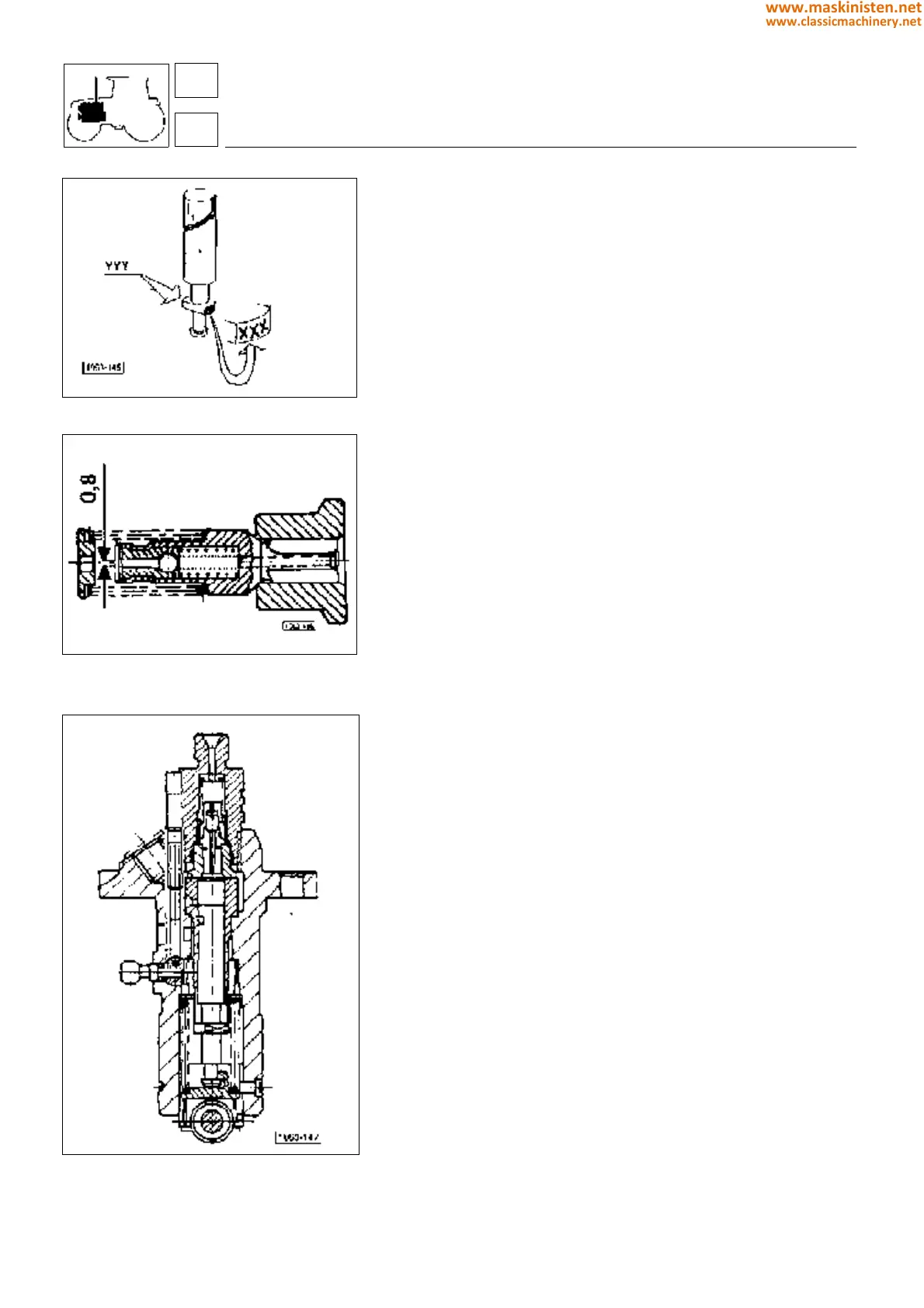

Fig. 12 - Injection pump G.D.V. valve.

Fig. 13 - Injection pump section 2.4619.050.0/20.

Positioning the pumps (fig. 10).

Before positioning the pumps, lock the control rod using tool

5.9030.728.0, which is to be positioned with the governor removed

and as shown in figure 10.

Then position each injection pump (interposing a shim pack of the

predetermined thickness), so that the dog engages the fork in the

control rod.

Rotate the pump clockwise until you feel the dog fully engage the

fork, then tighten the retaining screw.

NB: The pump must be positioned with the injection cams in b.d.c.

position.

Remove tool (B Fig. 10), release the pump by removing the lock

pin A (Fig. 10); fit the governor and the rear plug (flywheel end).

Check that the rod moves freely and that the STOP control

operates correctly.

Servicing

All the pumps are interchangeable as all the plungers are of the

same type.

N.B: new plungers can be identified from the markings in the

positions shown in figure 11.

Removal and refitting of an injection pump without replacing

components.

This operation does not require the use of any special tools. Refit

the pump using a shim pack of the original thickness.

Hold the pump control rack in position using lock pin A (fig. 10) to.

To do this, operate the STOP control lever so that the pin engages

the relative notch on the pump control rod rack.

Install the pump (also equipped with a rack lock pin) in the cylinder

block, making sure that the dog engages in the fork of the control

rod; then rotate the pump in a clockwise direction whilst simulta-

neously pushing the control rod through the engine inspection

flange towards the front of the engine.

Removal and refitting of a pump after replacing one or more

components

Before installation the pump must be re-calibrated on a test bench.

Remove any previous timing marks and stamp a new notch and

dimension (Y) on the pump.

Refit the pump using a shim pack (see fig. 16) according to the

new dimension stamped on the pump (always make a note of the

old value stamped on the pump before erasure, in order to facilitate

calculation of the new shim pack thickness) and follow the instruc-

tions given in the previous point.

Replacing a pump

The thickness of the shim pack (X +Y) must be corrected by first

removing shims to the thickness

indicated on the previous pump and then adding shims to the value

indicated on the new pump.

engine

fuel system

16

1

78

www.maskinisten.net

www.classicmachinery.net

Loading...

Loading...