2.6

SEL-551 Relay Instruction Manual Date Code 20110408

Installation

Rear-Panel Connections

and many industry applications have proven the performance of these

connectors. In addition, we have tested these connectors thoroughly to ensure

that they conform to our standards for protective relay applications.

Terminal Block

Make terminal block connections with size #6-32 screws using a Phillips

®

or

slotted screwdriver. You may request locking screws from the factory. Refer to

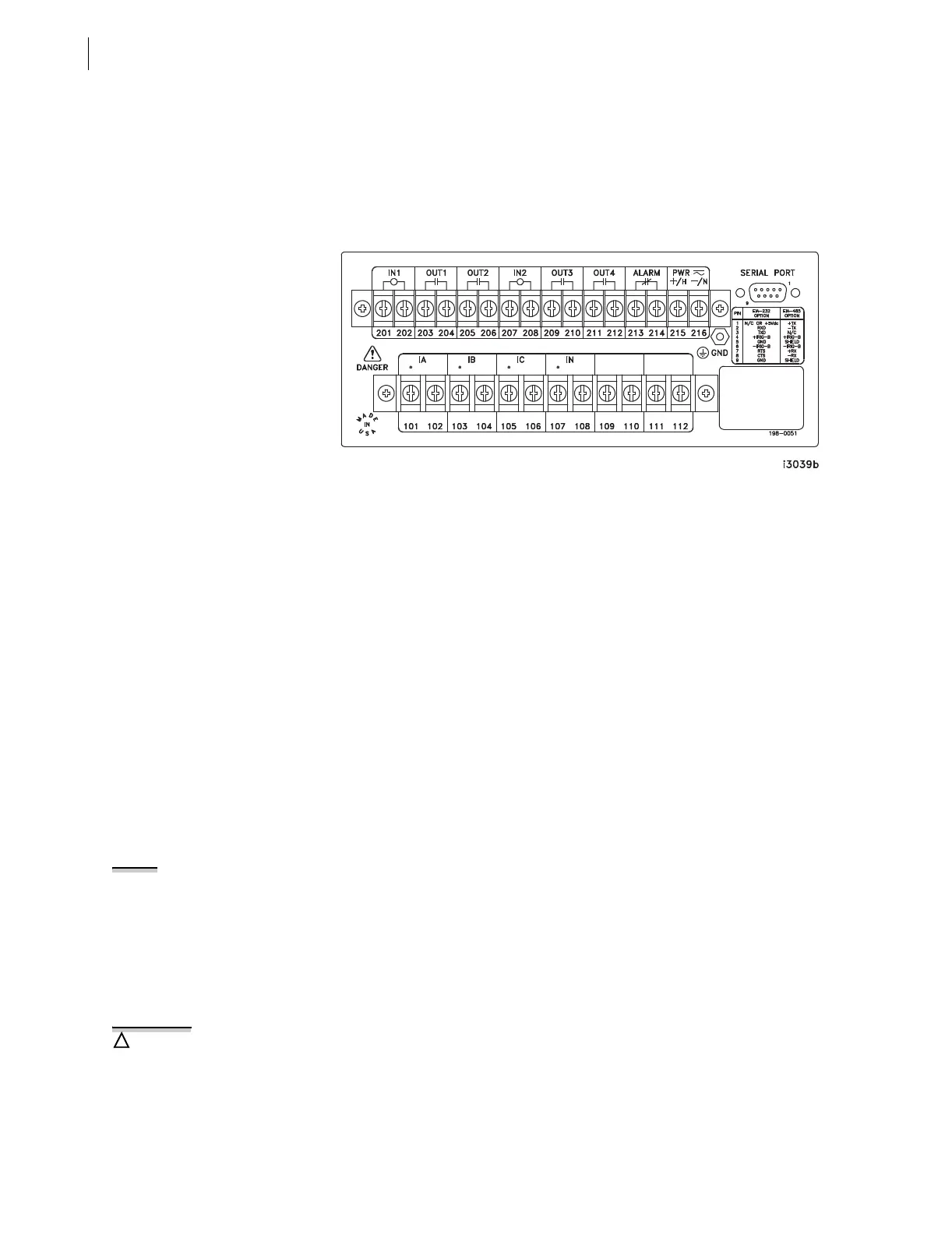

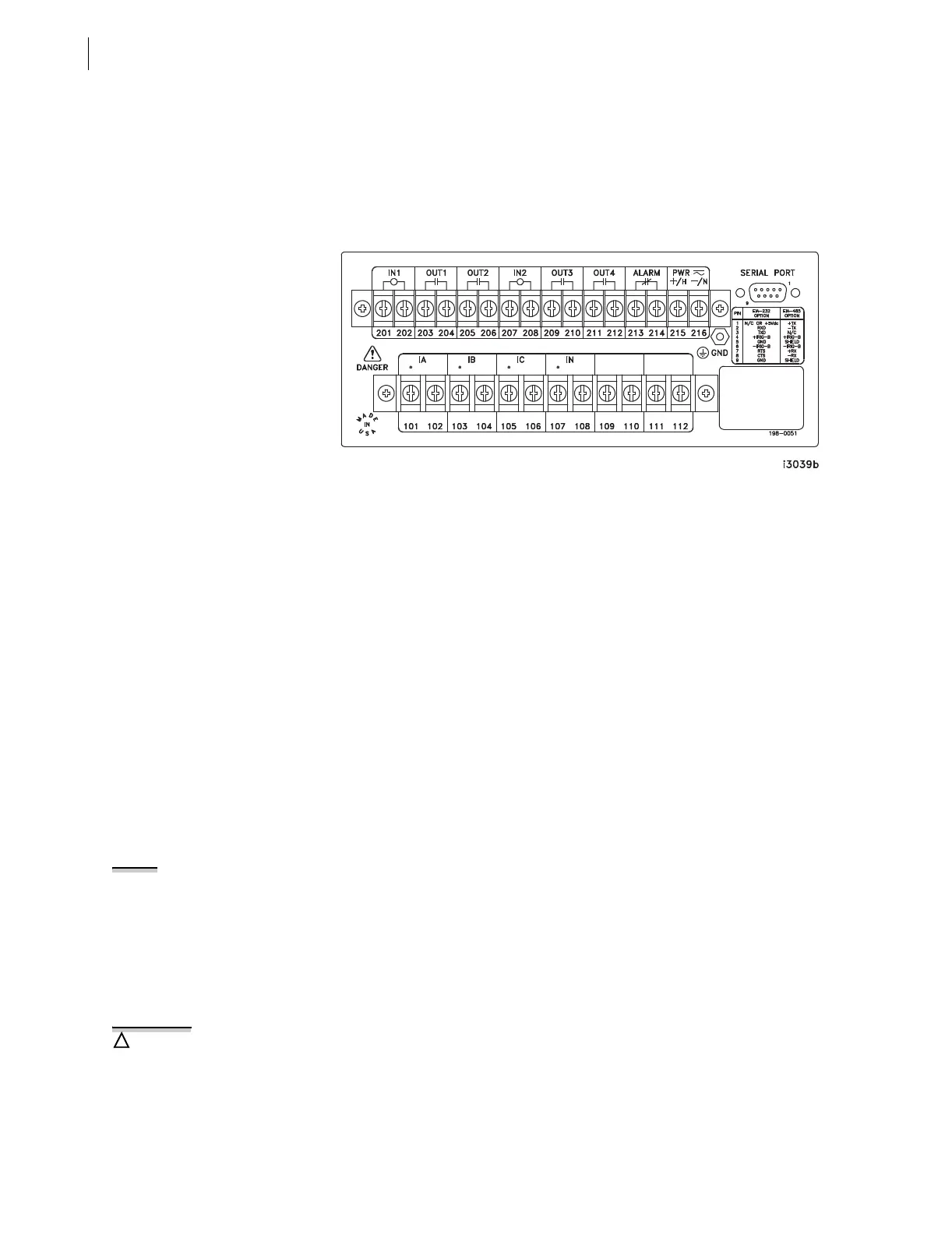

Figure 2.7 to make all terminal block connections.

Figure 2.7 SEL-551 Rear Panel (Conventional Terminal Blocks Option)

The output contacts in Figure 2.7 (OUT1–OUT4 and ALARM) are not polarity

dependent.

The optoisolated inputs in Figure 2.7 (IN1–IN2) are not polarity dependent.

All screws are size #6-32.

Screw Terminal Connections

All screw/washer styles on SEL relays are recognized by UL for field wiring

using terminals or bare wire. However, as stated below, SEL strongly

recommends the use of ring or fork terminals.

Two types of screw terminal are provided on the SEL relays, one with a

washer (Phillips screw head - standard) and one without (slotted screw head,

optional). SEL recommends using ring or fork terminals with both types of

screw terminals fitted to the relays. There are two main reasons for this

recommendation;

Step 1. Stray strands and inconsistent wire stripping may compromise

hi-pot clearances and give rise to the potential for shorting the

adjacent terminals.

Step 2. Wire/terminal secureness with ring terminals has been tested at

SEL to 20 lb minimum. Bare wire has not been tested at SEL.

Both the terminal block manufacturer and UL requirements have qualified the

standard terminal blocks for use with bare stranded wire, however, SEL’s

qualification requirements are more stringent as required by the utility and

industrial applications of protective relays.

The SEL terminal retention and hi-pot test voltage requirements are both

twice that required by the UL standard.

All SEL qualification testing of terminal blocks and relays is performed with

ring or fork terminals.

NOTE: #6 ring and fork terminals

will accommodate wire sizes from 22

awg to 10 awg.

There is no limit to the number of

terminals that can be clamped under

one screw, however there is a

maximum total thickness of .120" (3

mm). Ring terminals typically range in

thickness .030" to .060".

A too-long screw will damage the

inside part of the terminal. This is true

for both styles of terminal block, but

especially for the I/O connections.

Loading...

Loading...