MX-2300/2700 N/G SELF DIAG AND TROUBLE CODE 8 – 13

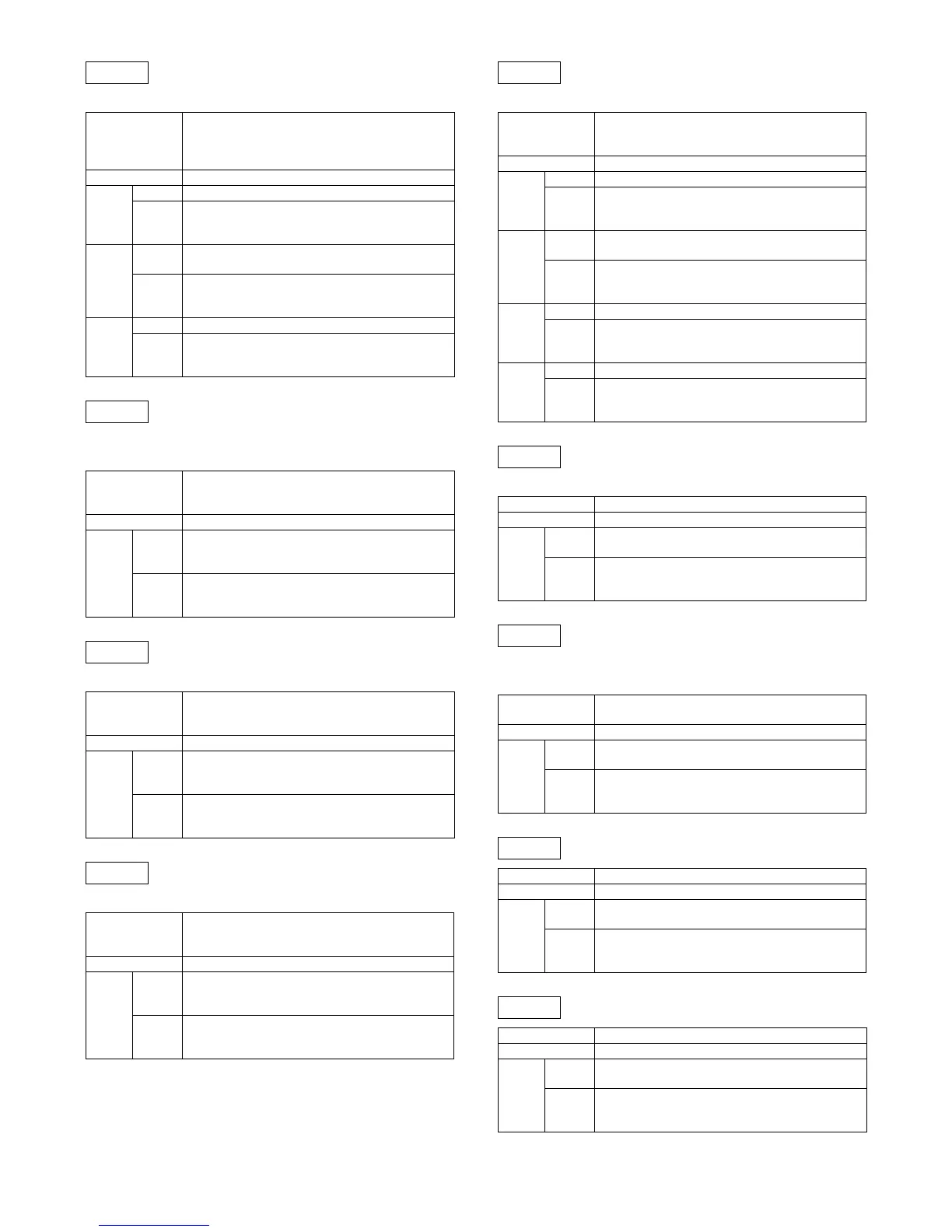

E7-90 Communication trouble between the

controller and the engine

EE-EC Auto developer adjustment trouble

(The sample level for every rotation is

other than 128 ± 10).

EE-EL Auto developer adjustment trouble

(overtoner error)

EE-EU Auto development adjustment trouble

(Under-toner abnormality)

F1-00 Finisher communication trouble

(Machine side detection)

F1-02 Saddle finisher transport motor trou-

ble

F1-03 Finisher paddle motor trouble (MX-

FNX2), finisher swing motor trouble

(MX-FNX1)

F1-08 Finisher stapler shift motor trouble

F1-10 Finisher staple motor abnormality

Trouble content Communication trouble between the MFP and the

PCU (MFP detection)

Communication establishment error/Framing/Parity/

Protocol error

Section MFP

Case 1 Cause PCU PWB connector connection trouble

Check

and

remedy

Check the connector connection between the PCU

PWB and the MFPcnt PWB.

Case 2 Cause Harness trouble between the PCU PWB and the

MFPcnt PWB

Check

and

remedy

Check the harness between the PCU PWB and the

MFPcnt PWB.

Case 3 Cause Broken connector pin of the PCU PWB mother board

Check

and

remedy

Check grounding of the machine.

Trouble content Auto developer adjustment trouble (The sample level

for every rotation is other than 128 ± 10.) <Detection

only with SIM25-2, no trouble memory, only display>

Section PCU

Case 1 Cause Toner density sensor trouble, charging voltage/

developing voltage trouble, toner density trouble,

developing unit trouble, PCU PWB trouble

Check

and

remedy

Use SIM25-2 to execute the auto development

adjustment.

Trouble content The sample level is 76 or below, or the control voltage

is 208V or above. <Detection only with SIM25-2, no

trouble memory, only display>

Section PCU

Case 1 Cause Toner density sensor trouble, charging voltage/

developing voltage trouble, toner density trouble,

developing unit trouble, PCU PWB trouble

Check

and

remedy

Use SIM25-2 to execute the auto development

adjustment.

Trouble content The sample level is 178 or above, or the control

voltage is 51V or below. <Detection only with SIM25-

2, no trouble memory, only display>

Section PCU

Case 1 Cause Toner density sensor trouble, charging voltage/

developing voltage trouble, toner density trouble,

developing unit trouble, PCU PWB trouble

Check

and

remedy

Use SIM25-2 to execute the auto development

adjustment.

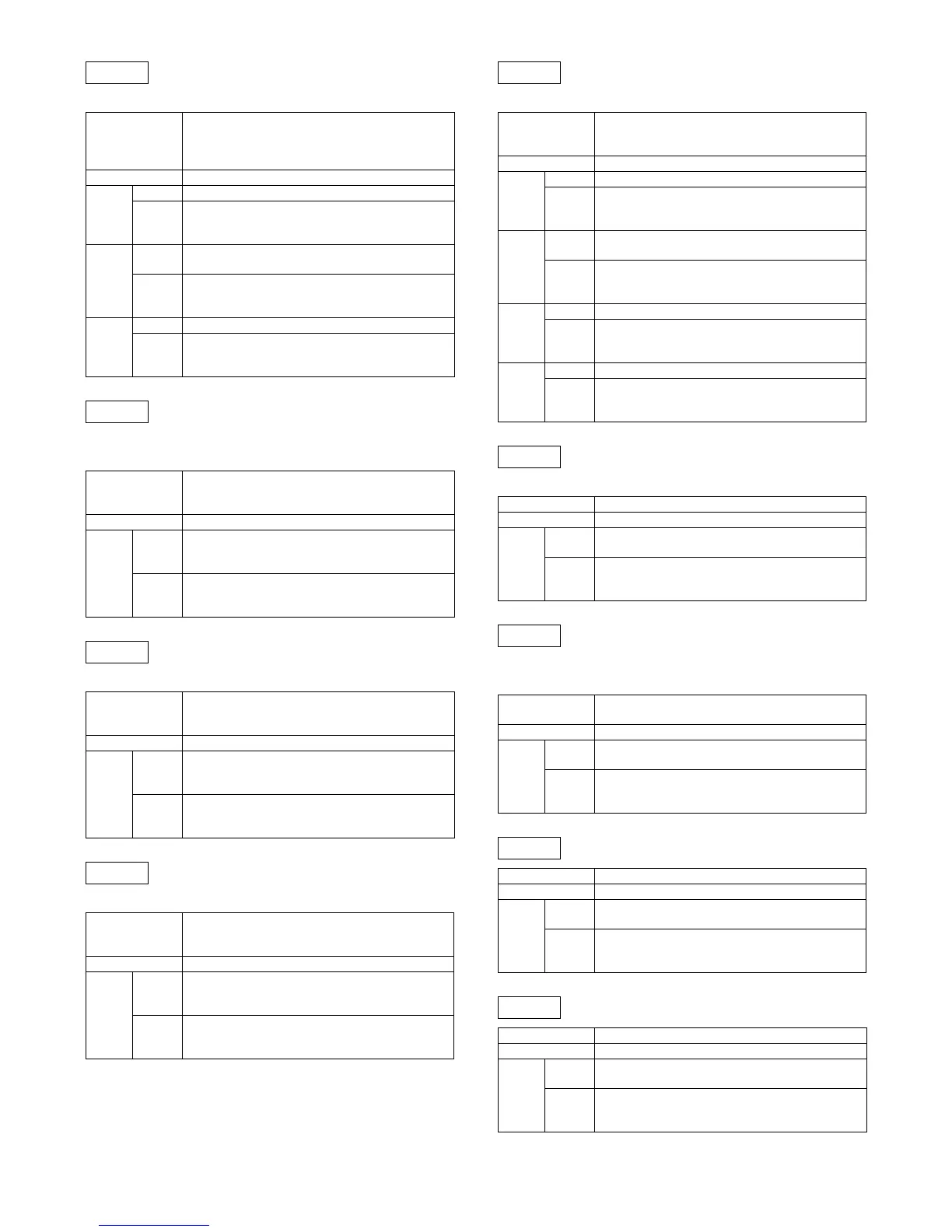

Trouble content Communication line test error when turning on the

power or after canceling an exclusion simulation.

Communication error with the finisher

Section PCU

Case 1 Cause Malfunction due to noises

Check

and

remedy

Turn OFF/ON the power to cancel.

Case 2 Cause PCU finisher connector or harness connection error or

disconnection

Check

and

remedy

Check the connector and harness in the

communication line.

Case 3 Cause Finisher control PWB trouble

Check

and

remedy

Replace the finisher control PWB.

Case 4 Cause Control PWB (PCU) trouble

Check

and

remedy

Replace the PCU PWB.

Trouble content Transport drive motor trouble

Section PCU

Case 1 Cause Motor lock, motor RPM abnormality, motor

overvoltage, saddle finisher control PWB trouble

Check

and

remedy

Use SIM3-3 to check the operation of the transport

motor (FFM).

Replace the finisher control PWB.

Trouble content Paddle motor operation trouble (MX-FNX2)

Swing motor operation trouble (MX-FNX1)

Section PCU

Case 1 Cause Motor lock, motor RPM abnormality, motor

overvoltage, finisher control PWB trouble

Check

and

remedy

Use SIM3-3 to check the operation of the motor (FPM/

FSWM).

Replace the finisher control PWB.

Trouble content Stapler shift motor operation trouble

Section PCU

Case 1 Cause Motor lock, motor RPM abnormality, motor

overvoltage, finisher control PWB trouble

Check

and

remedy

Use SIM3-3 to check the operation of the staple motor

(FSM).

Replace the finisher control PWB.

Trouble content Staple operation trouble

Section PCU

Case 1 Cause Motor lock, motor RPM abnormality, motor

overvoltage, saddle finisher control PWB trouble

Check

and

remedy

Use SIM3-3 to check the operation of the staple motor

(FFSM).

Replace the finisher control PWB.

Loading...

Loading...