MX-2300/2700 N/G FUSING SECTION N – 2

2. Operational descriptions

A. Fusing unit drive

To drive the fusing unit, the drive power is transmitted from the

drive motor (FUM) through the connection gear to the upper heat

roller gear.

The drive motor (stepping motor) is driven according to the control

signal sent from the PCU.

B. Heater lamp drive

The surface temperature of the heat roller detected by the ther-

mistor is sent to the PCU. When the temperature is lower than the

specified level, the heater lamp lighting signal is sent from the PCU

to the heater lamp drive circuit in the sub power PWB.

The power triac in the heater lamp drive circuit is turned on, and the

AC power is supplied to the heater lamp, lighting the lamp and

heating the heat roller.

To prepare for an abnormally high temperature of the heat roller,

the thermostat is provided for safety.

When the thermostat is opened, power supply (AC line) to the

heater lamp is cut off.

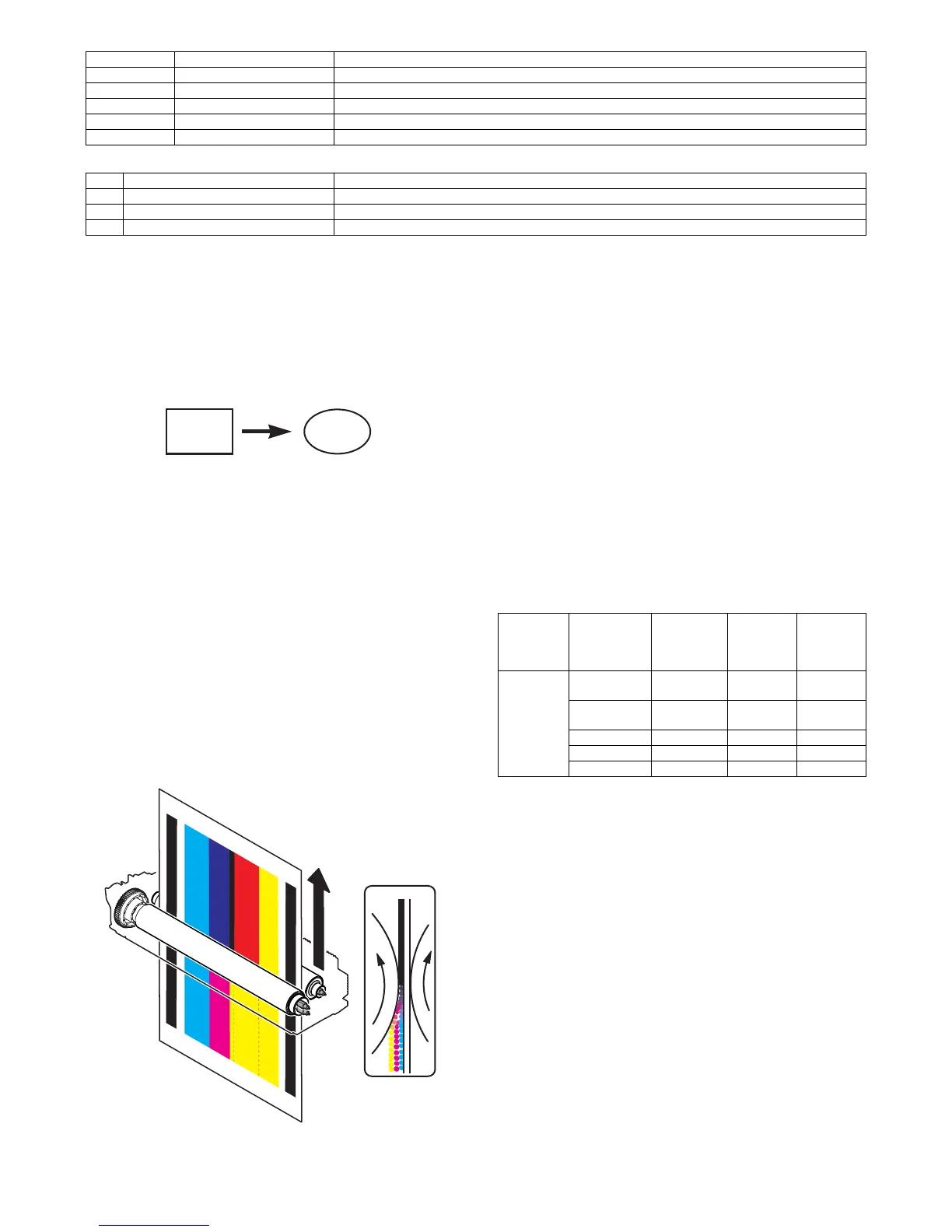

C. Fusing operation

Color toner of YMCK on paper is heated and pressed by the heat

rollers to be fused on paper.

At that time, color toner of YMCK is mixed to reproduce nearly

actual colors of document images.

The upper and the lower heat rollers are provided to heat from

above and below.

This is because it is necessary to heat four layers of toner from

above and below and right and left to fuse it on paper.

The upper and lower heat rollers are of silicon rubber.

This is because of the following reasons:

1) To provide a greater nip quantity and a higher heating capacity

for paper.

2) The soft, flexible rollers press multi-layer toner without defor-

mation to fuse on paper.

3) An even pressure is applied to an uneven surface of multi-

layer toner.

D. Fusing temperature control

The temperature sensors are provided at the center and the edges

of the upper heat roller, and at the center of the lower heat roller.

The heat roller temperature is detected by the temperature sensors

to control the heater lamp so that the temperature is maintained at

the specified level.

The fusing temperature is switched according to the machine con-

dition and paper type selected.

HL_US Heater lamp (2) Heats the fusing roller (heating).

RTH3 Fusing temperature sensor (3) Detects the surface temperature of the fusing roller (heating).

HLTS3 Thermostat (3) Shuts conduction to the heater lamp when the temperature rises abnormally. [For the fusing roller (heating)]

HL_LM Heater lamp (3) Heats the fusing roller (heating).

FUM Fusing motor Drives the fusing unit.

No. Name Function/Operation

1 Fusing roller (Heating) Heat and presses toner on paper to fuse it on paper.

2 Pawl Paper which was not separated naturally from the fusing roller (heating) is mechanically separated.

3 Fusing roller (pressing) Heat and presses toner on paper to fuse it on paper.

Signal name Name Function/Operation

FUMPCU

Mode Paper

Fusing

roller center

(heating)

main

Fusing

roller

(heating)

sub

Fusing

roller

(pressing)

Ready state

Print mode

B/W normal

paper

170 180 130

Color normal

paper

170 180 130

Heavy paper 170 175 140

OHP 170 170 145

Envelope 180 180 145

Loading...

Loading...