16 FLOWSIC600-XT · Operating Instructions · 8018846/1BHP/V2-1/2021-05 · © SICK Engineering GmbH

Product description

Subject to change without notice

2.1 Measuring principle

The FLOWSIC600-XT measuring system works according to the principle of ultrasonic tran-

sit time difference measurement. This allows conclusions to be made on the gas volume

flowing through based on the sound velocity transfer time. Measurement is carried out in a

direct path layout to keep disturbing effects such as gas flow turbulence, dirt, moisture or

interfering noises as low as possible. Two ultrasonic transducers are positioned opposite

each other in a defined angle to the gas flow and operate alternately as sender and

receiver.

2.2 System components

The FLOWSIC600-XT measuring system consists of the following hardware components:

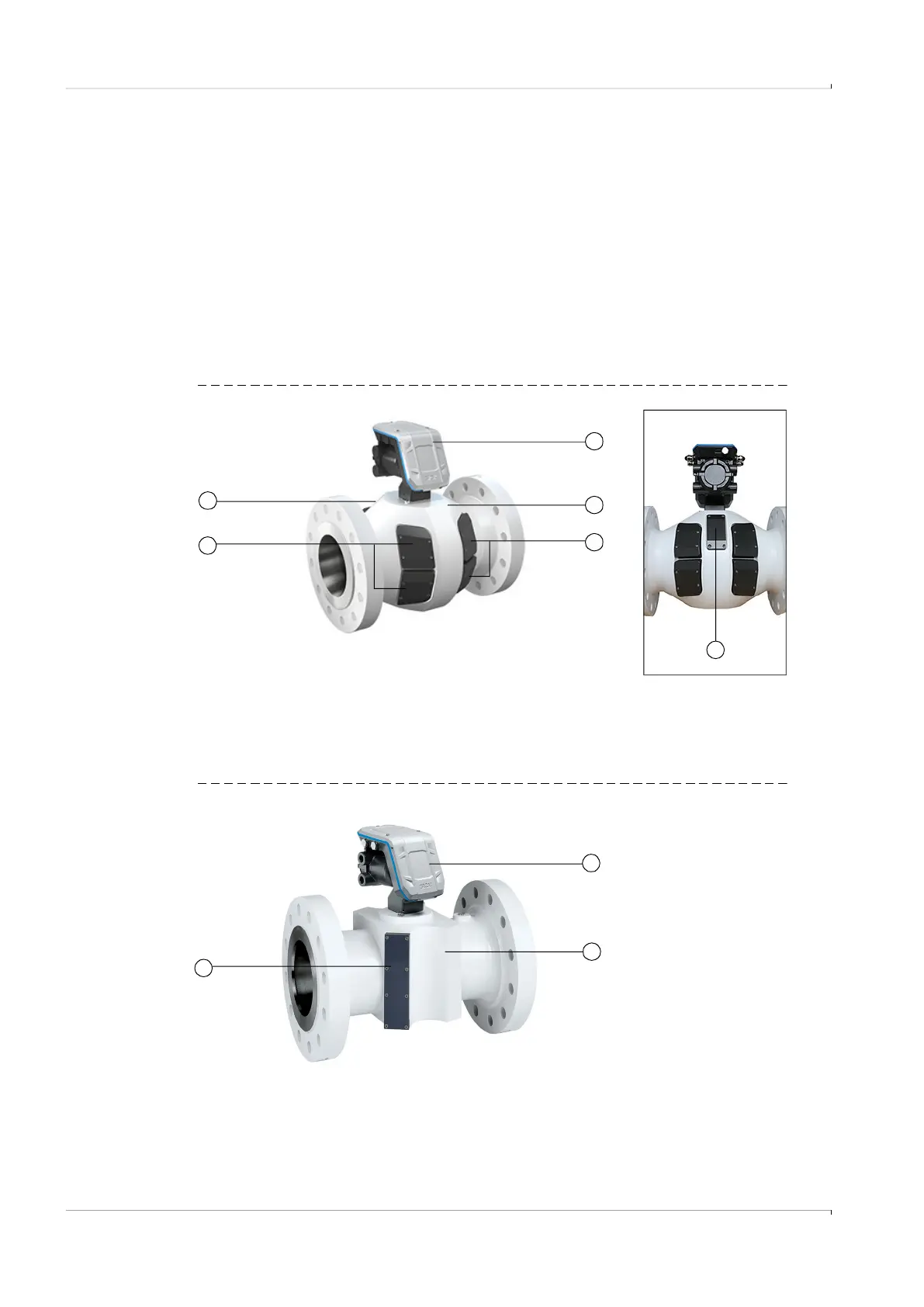

Fig. 2 Overview FLOWSIC600-XT

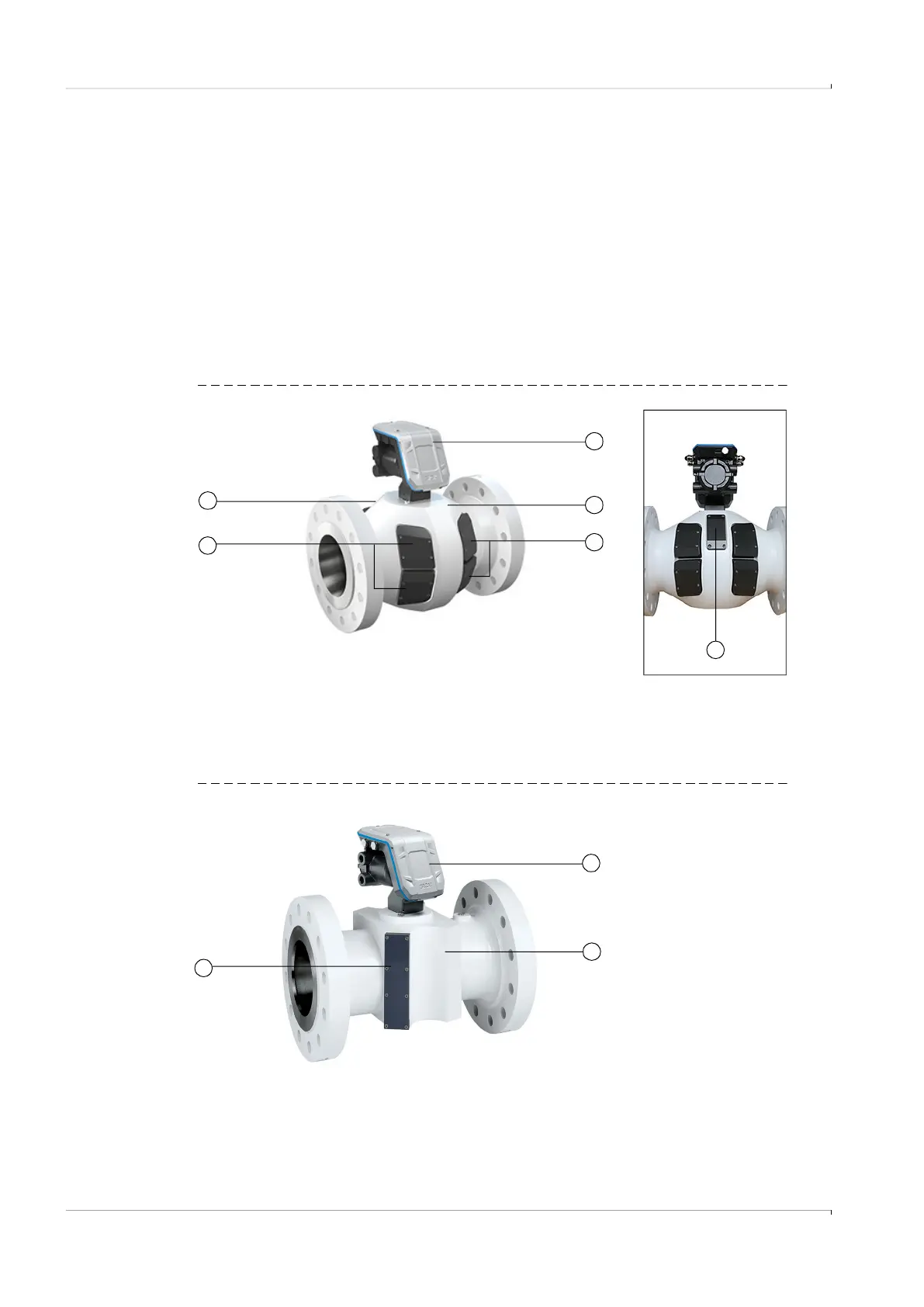

Fig. 3 Overview FLOWSIC600-XT C

1

2

3

3

4

1 Signal Processing Unit

2 Meter body

3 Cover caps for ultrasonic transducers

4 Cover cap for integrated pressure and temperature sensor

Rear view

4

1 Signal Processing Unit

2 Meter body

3 Cover cap for ultrasonic transducers

3

1

2

Loading...

Loading...