Commissioning and Operation

FLOWSIC600-XT · Operating Instructions · 8018846/1BHP/V2-1/2021-05 · © SICK Engineering GmbH 91

Subject to change without notice

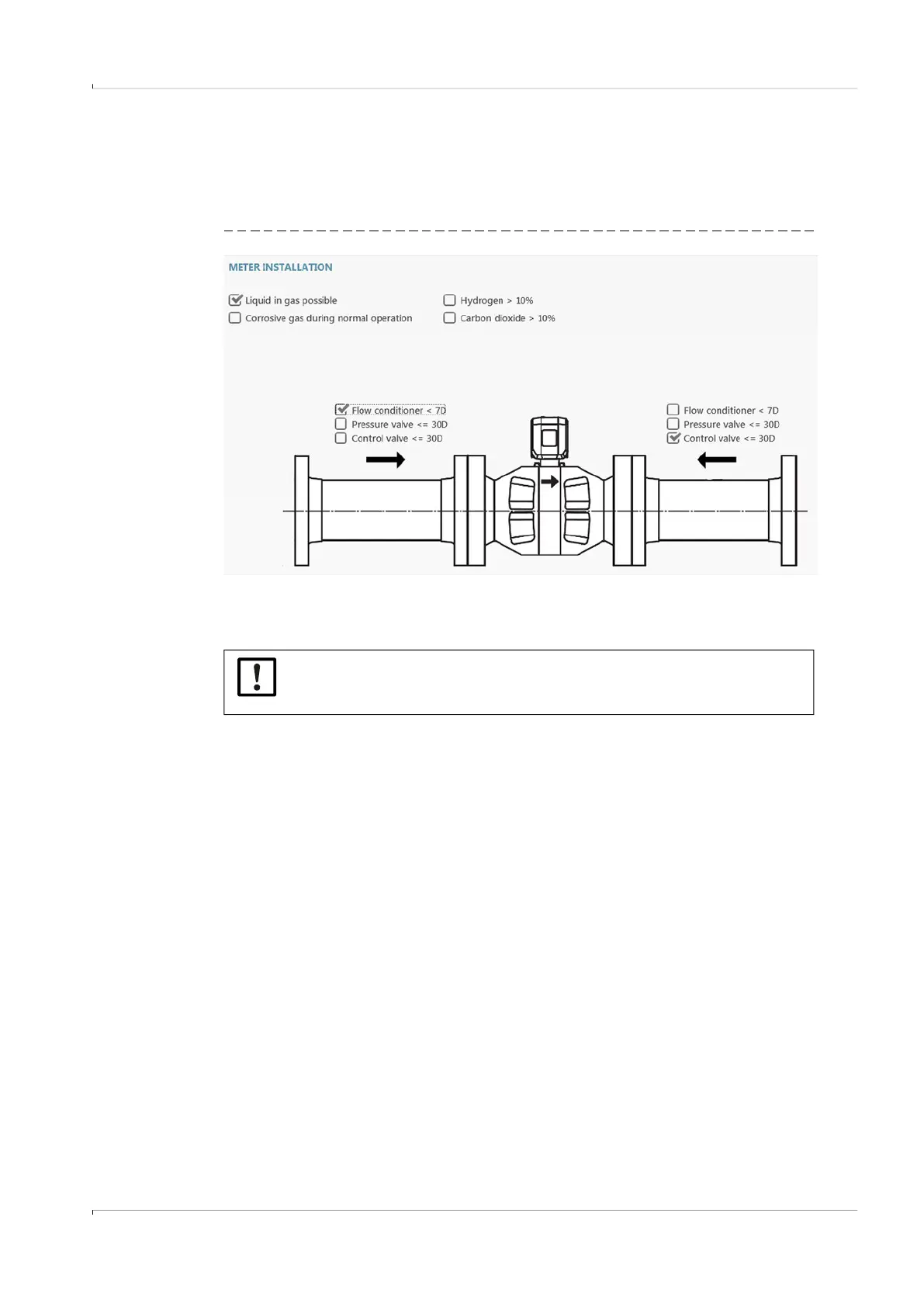

4.3.2.8 Meter installation

Specifications on the installation conditions of the gas flow meter are relevant for trouble-

shooting with i-diagnostics

TM

.

The arrow symbol on the gas flow meter shown identifies the primary flow direction.

Fig. 43 Installation conditions (example)

4.3.2.9

Completion

▸

First write the data to the device.

▸

If desired; Reset the malfunction volume encoder totalizer and clear the logbooks.

▸

SICK recommends creating a Parameter report and a Maintenance report and archiving

the reports with the delivery documentation, → p. 101, §5.2.4.

4.4 Function check after commissioning

4.4.1 Recommended checks:

▸

Checking the meter state, → p. 96, §5.2.1.

▸

Checking the signal acceptance rate, → p. 92, §4.4.2.

▸

Zero phase check, → p. 92, §4.4.3.

▸

Checking the speed of sound, → p. 93, §4.4.4.

▸

Comparing theoretical and measured sound velocity (SOS), → p. 98, §5.2.2.

NOTICE:

The data must be written to the device before the report is created otherwise

the reports are created using the data from commissioning.

Loading...

Loading...