Installation

FLOWSIC600-XT · Operating Instructions · 8018846/1BHP/V2-1/2021-05 · © SICK Engineering GmbH 71

Subject to change without notice

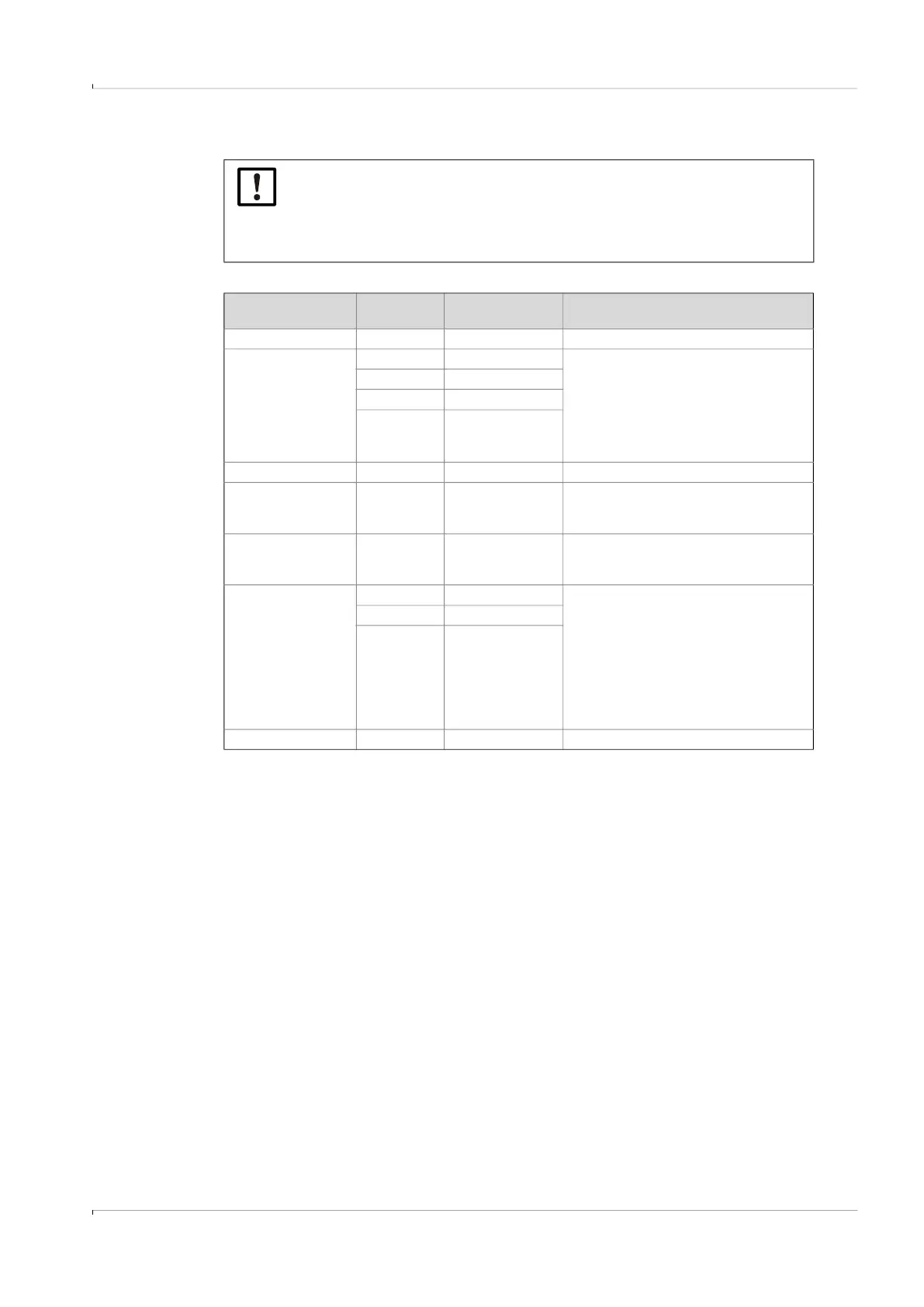

3.4.8.2 Connection parameters Ex-d and Ex-e

Table 6 Connection parameters Ex-d and Ex-e

NOTICE: Safety-relevant parameters Ex-i

The connection parameters in → Table 6 do not apply for the Ex- i installation.

Safety-relevant parameters for Ex-i installation, see → p. 132, §9.1 for

installation according to ATEX/IECEx and → p. 141, §9.2 for installation

according to CSA.

Ex-d

(→ p. 73)

Ex-e

(→ p. 75)

Connection parameters

Power supply Power 1 + 2 10.8 ...26.4 VDC, max. 400 mA

Switching outputs DO.0/FO.0 13+14 Open Collector, max. 30 VDC,

max. 50 mA,

switching frequency DC ...10 kHz,

recommended switching current

2 mA < Ic < 20 mA,

load resistance R

load

= U / Ic,

alternative NAMUR characteristic

DO.1/FO.1 15+16

DO.2 17+18

DO.3 19+20

Encoder Encoder 9+10 NAMUR, 1.2 kbit/s, UART protocol 7E1

Active current output AO 5-8 24 VDC, 3.6 ...24 mA,

alternative external auxiliary voltage

max. 30 V,

Pressure and tem-

perature sensor sys-

tem

pT

(HART Master)

3+4

[1]

[1] If configured

Configuration options and power input of possible configurations, see → p. 158, §9.4.

24 VDC, max. 24 mA,

RS485 RS485.1 21+22

[1]

EIA-485, max. 57.6 kbit/s,

termination 150 Ohm switchable

Configuration of the RS485.1 interface at

the factory:

– Protocol type: MODBUS-RTU

– Modbus configuration: FL600XT

(standard)

– Baud rate: 38,400 baud

– Bit protocol: 8N1

RS485.2 3+4

[1]

RS485.3 9+10

[1]

Ethernet Ethernet 9-12

[1]

10/100 Mbit/s, protocol Modbus TCP

Loading...

Loading...