22

8014084/ZWT7/V3-1/2020-06 | SICKOPERATING INSTRUCTIONS | TRANSIC111LP

Subject to change without notice

3 INSTALLATION

3.3.3 TRANSIC111LP installation - extractive

Filter recommendation

● Stainless steel filter: Minimum protection against dirt particles

● PTFE filter: For gas with humidity and/or fine dirt particles

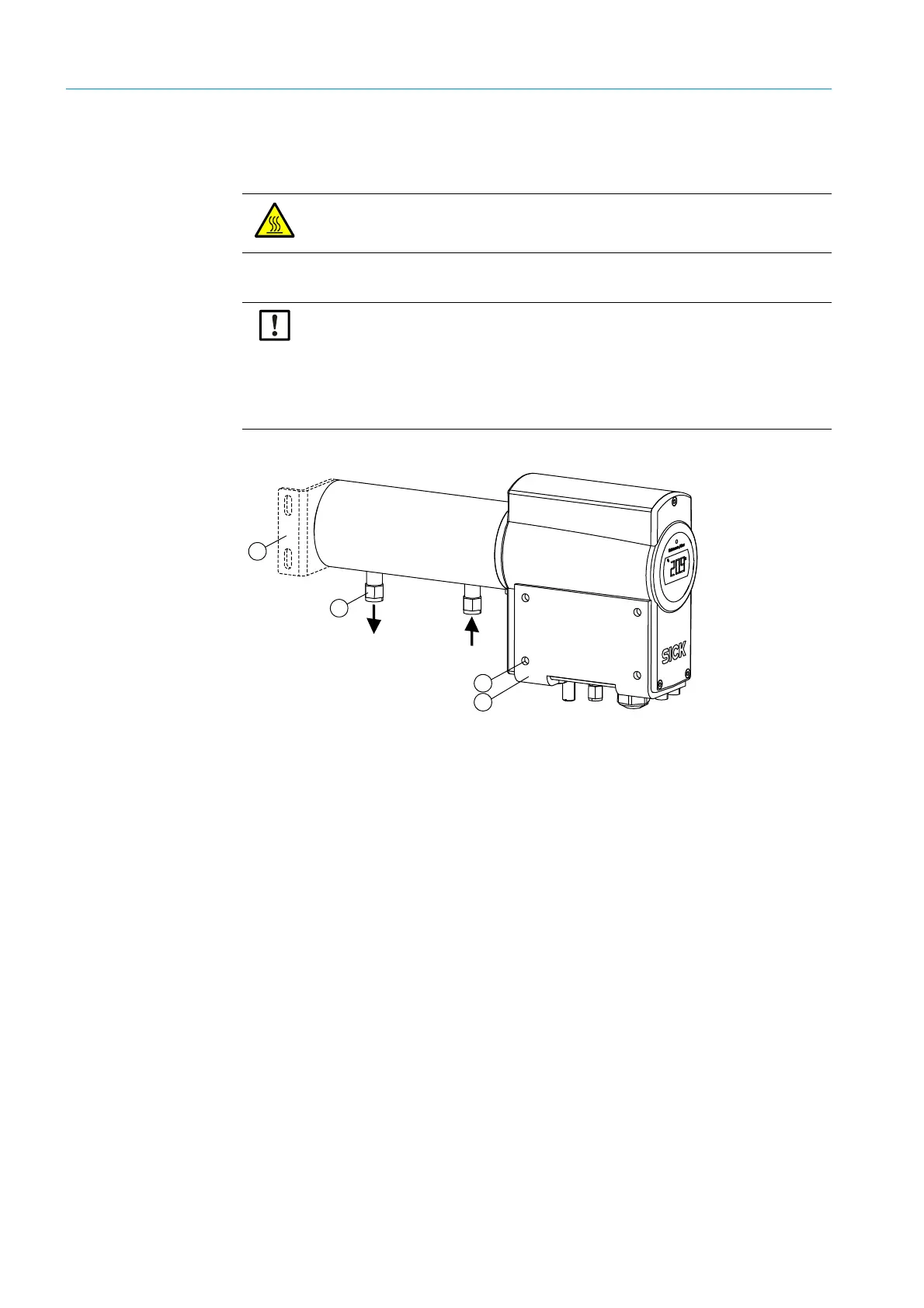

Fig. 7: TRANSIC111LP with sample gas cell

Installing the wall bracket

1 Fasten the wall bracket.

Wall bracket dimensions, see “ TRANSIC111LP with wall bracket and sample gas cell”,

page 99.

2 Fasten the TRANSIC111LP

1 Install the TRANSIC111LP on the wall bracket using the four M6 screws provided.

2 First fix both outer screws in the threads at the bottom of the TRANSIC111LP. This

simplifies fastening the two inner screws when positioning the TRANSIC111LP on the

wall bracket.

3 Tighten all four screws.

CAUTION: Risk of burns through hot gas

▸ Attach the enclosed warning label to the sample gas cell surface when process

temperatures are >65 °C.

NOTICE: Preparing the gas sample for dirty and wet gas

▸ Filter and dry the gas sample before pumping it into the sample gas cell.

▸ Use a hydrophobic dust filter before the inlet opening of the sample gas cell to

protect the optical components against particle and water.

▸ Replace the dust filter regularly to ensure sufficient throughflow.

▸ Dry the gas through cooling and reheating to guard against condensation in the

sample gas cell.

1 = Optionally available assembly bracket

2 = Swagelok connections for Ø 6 mm gas tubes (in scope of delivery: Adapter for 1⁄4")

3 = Max. screw size M6

4= Wall bracket

Loading...

Loading...