SYSTEM DESCRIPTION 3

8026362 / V1-0/2022-03|SICK

Subject to change without notice

SUPPLEMENTARY OPERATING INSTRUCTIONS | VMS4100/5100

• In an area before and after the measuring station, the conveying equipment must run

straight and evenly. The conveyor belt must have a uniform and flat surface. The front

and back area corresponds to the maximum length of the measuring object (see also

section 3.7 Nominal operating conditions).

NOTE! If the specific installation position of the measuring system fails to satisfy this

requirement, the maximum length for the measuring objects must be restricted

accordingly and indicated on the identification label (see section 3.8.1 Information

labels).

• Positive or negative slopes of the conveying equipment must be kept flat enough to

prevent the measuring objects from sliding.

• The conveying equipment must not have any shiny or reflective surfaces. This can have

a negative impact on the measurement results.

• No guides for measuring objects may be installed in the vicinity of the measuring

station.

3.9.3 Mounting requirements

▸

Use a stable frame that is secured to prevent twisting and has sufficient load-bearing

capacity.

▸

Attach the frame to the conveying system in such a way that it cannot shake or vibrate.

▸

Align the frame at a right angle to the conveying direction.

NOTE! Use Item aluminum profiles.

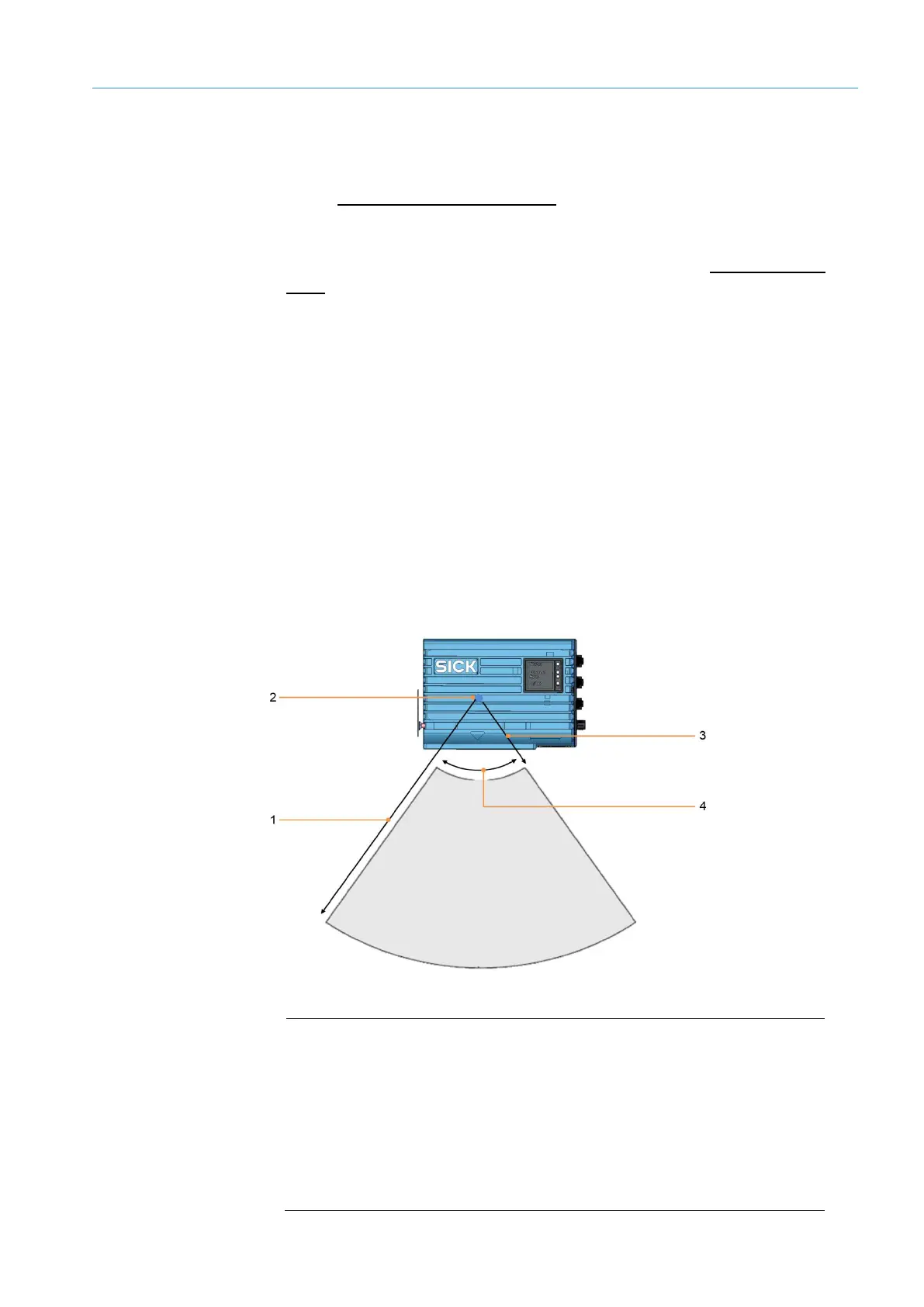

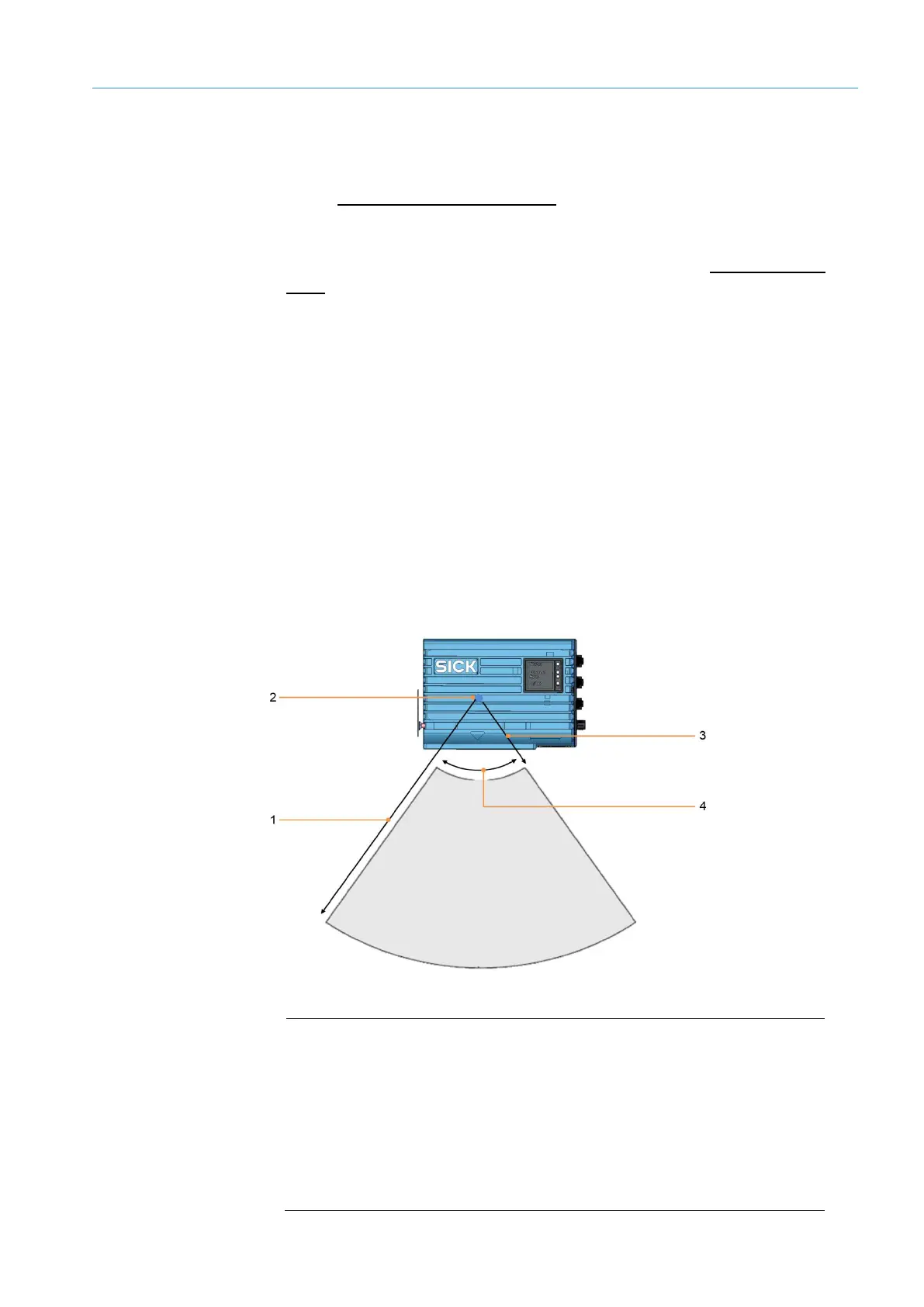

Fig. 60: Working range of the LMS4x21

Legend

1 Maximum working sensing range: 3 m

2 Zero point of the distance measurement. In the delivery state, this point

is the origin of the laser (marked with a point on the upper and lower

side of the housing).

3 Minimum distance between the zero point of the measurement and the

measuring object: 900 mm

4 Aperture angle: 70°

General requirements

Frame

LMS4x21

Loading...

Loading...