Functions

8.15 Brake functions

Control Units CU240S

Operating Instructions, 11/2006, A5E00766042B AA

8-79

U%LW

3

I

PLQ

3

3

3

U%LW

W

W

W

W

W

I

%UDNH

6WDWXV

0RWRUH[FLWDWLRQ

ILQLVKHG

212))2))

2))2))

21

2SHQ

&ORVHG

%UDNH5HOHDVH7LPH

%UDNH&ORVLQJ7LPH

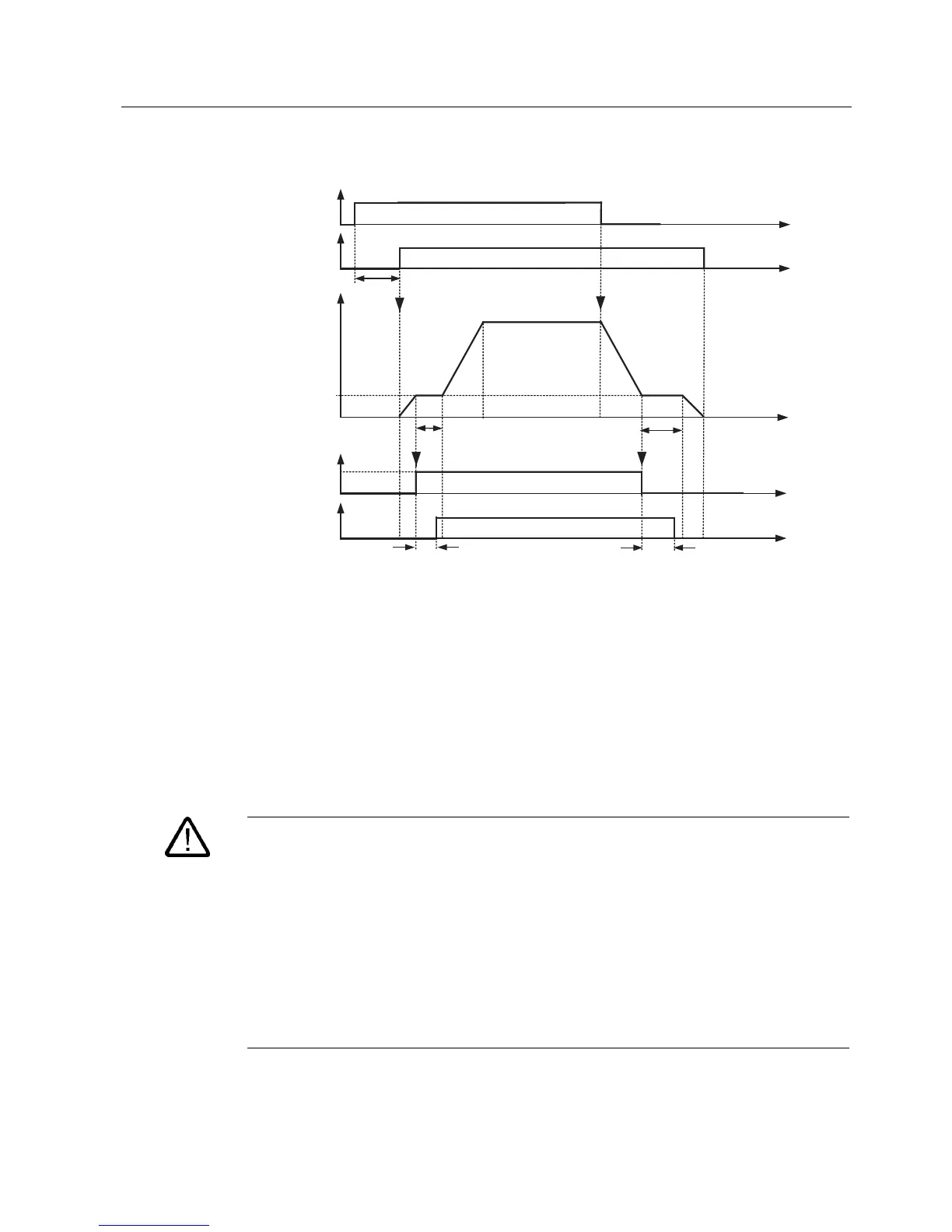

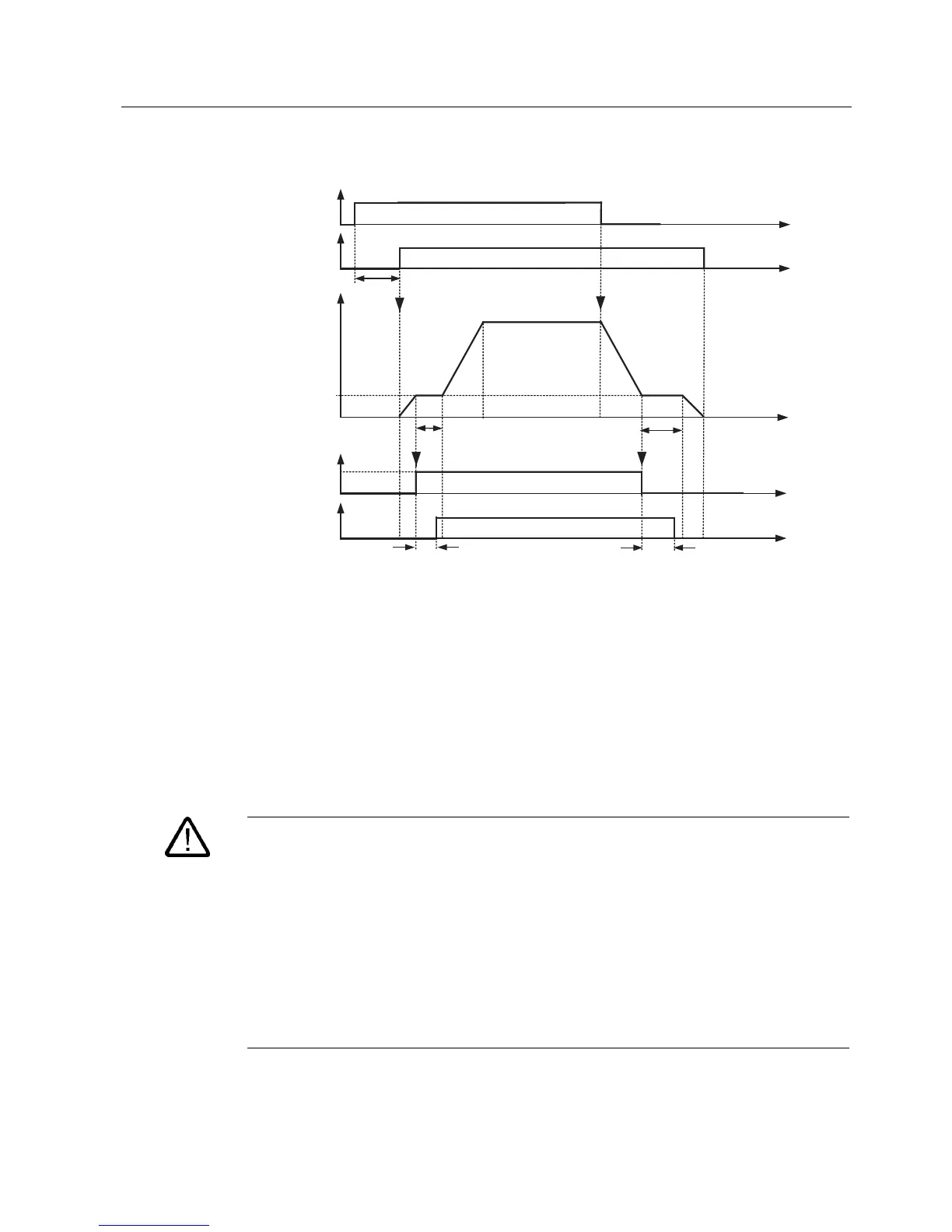

Figure 8-54 Motor holding brake after ON/OFF1 resp. ON/OFF3

The motor holding brake is either closed using OFF1 or OFF3. When the minimum

frequency P1080 is reached, the motor is operated at this frequency until the brake has been

applied (closing times of brakes are between 15 ms and 300 ms). The actual time is

specified using parameter P1217 "Holding time after ramp down" (see figure above). If, on

the other hand, an OFF2 command has been output, then independent of the motor state,

the status signal r0052 bit 12 "Brake active" is reset. This means that the brake immediately

closes after OFF2 (instant brake).

The mechanical brake is controlled using the status signal r0052 bit 12 "Brake active" of the

brake control. This signal is connected to terminal A and B of the power module.

Warning

It is not sufficient to select the status signal r0052 bit 12 "Brake active" in P0731 … P0733. In

order to activate the motor holding brake, in addition, parameter P1215 must also be set to

1.

If SINAMICS G120 controls the motor holding brake, then a series commissioning may not

be carried-out for potentially hazardous loads (e.g. suspended loads for crane applications)

unless the load has been secured. Potentially hazardous loads can be secured as follows

before series commissioning is started:

• Lower the load to the floor, or

• Clamp the load using the motor holding brake

(Caution: During the series commissioning, SINAMICS G120 must be prevented from

controlling the motor holding brake).

Loading...

Loading...