Functions

8.12 PID Controller

Control Units CU240S

8-56 Operating Instructions, 11/2006, A5E00766042B AA

...

+

1

...

...

...

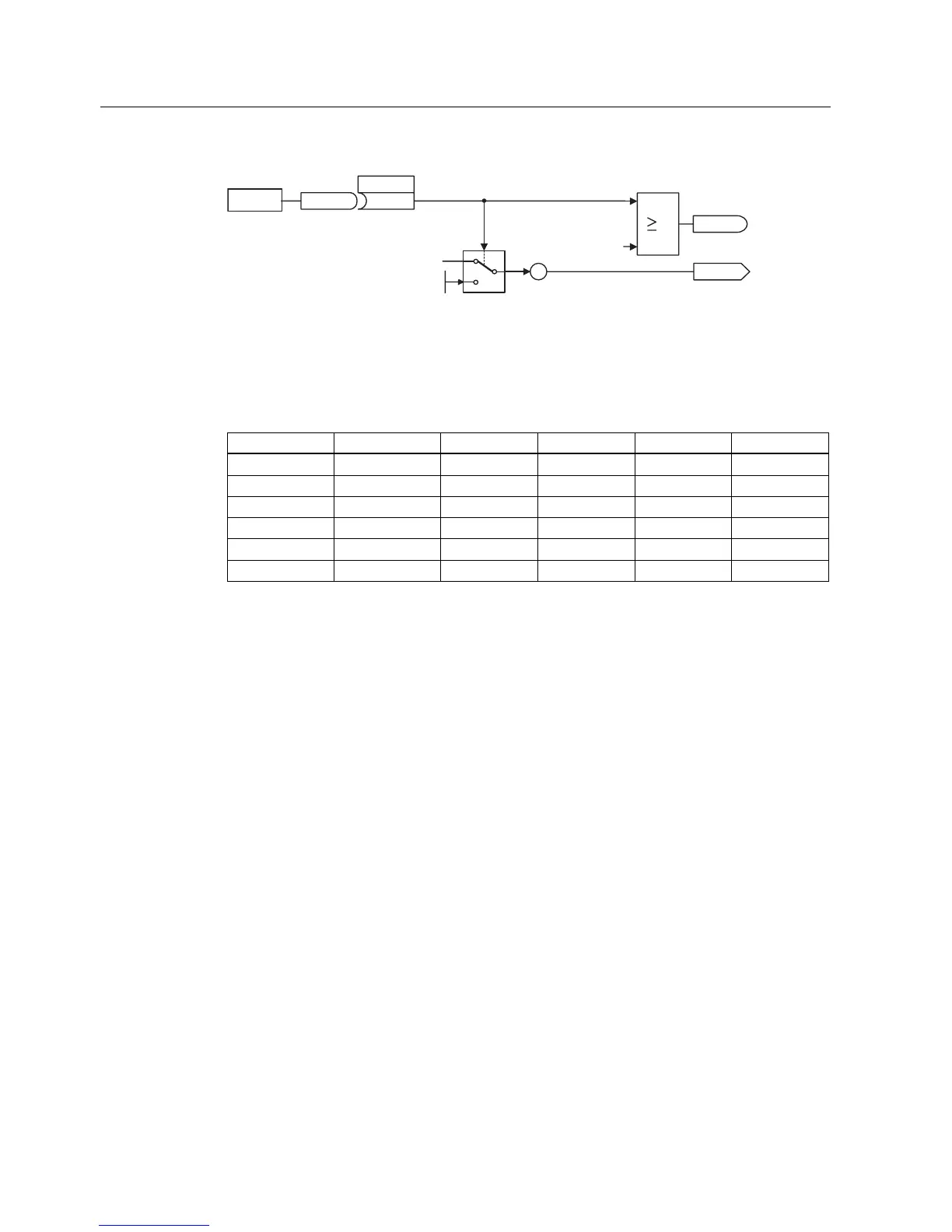

P2216 = 1

DI3 r0722

r2225

P2220

P2201

r2224

0

722:3

P0704 = 15 or P0704 = 99

Figure 8-37 Directly selected PID fixed setpoint using DI3

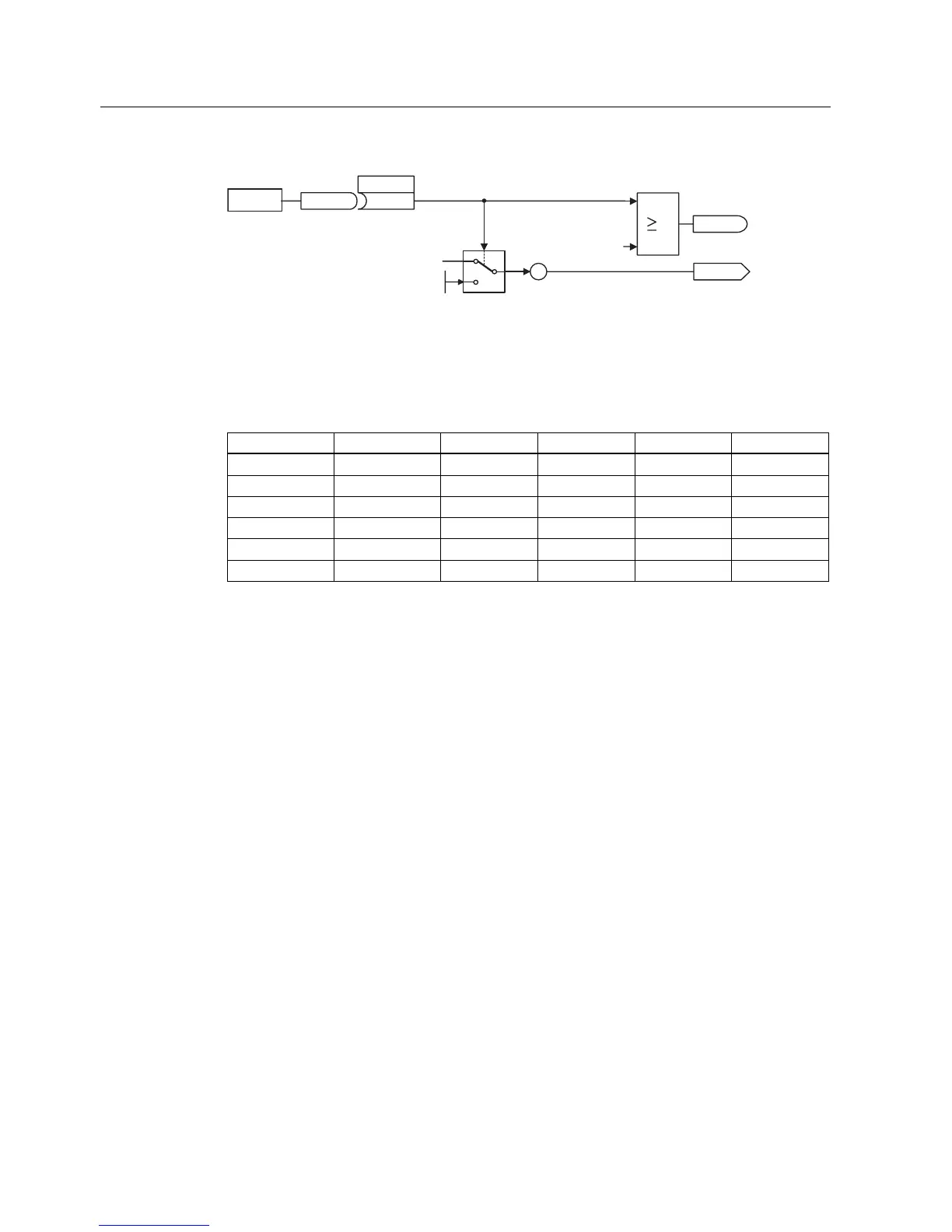

Binary-coded selection (P2216 = 2)

Table 8-23 Example of binary-coding using digital inputs

FF number Frequency P2223 P2222 P2221 P2220

PID-FF0 0 Hz 0 0 0 0

PID-FF1 P2201 0 0 0 1

PID-FF2 P2202 0 0 1 0

… … … … … …

PID-FF14 P2214 1 1 1 0

PID-FF15 P2215 1 1 1 1

8.12.3 PID dancer roll control

Data

Parameter range: P1070, P1075, P1120, P1121,

P2200, P2251 … P2285

Warnings: -

Fault: -

Function chart number: -

Description

For various continuous production processes, for example, in the paper and pulp industry or

in the manufacture of cables, it is necessary to control (closed-loop) the velocity of stations

along the production process so that the continuous material web is not subject to any

unwanted tension levels. It is important that no folds or creases are formed. For applications

such as these, it is practical to provide a type of material buffer in the form of a loop with a

defined tension. This provides a de-coupling between the individual inverter locations. This

loop represents the difference between the material fed-in and that fed-out and therefore

indicates the process quality.

Loading...

Loading...