Functions

8.15 Brake functions

Control Units CU240S

8-82 Operating Instructions, 11/2006, A5E00766042B AA

8.15.2 Electronic brakes (only with PM240)

Overview

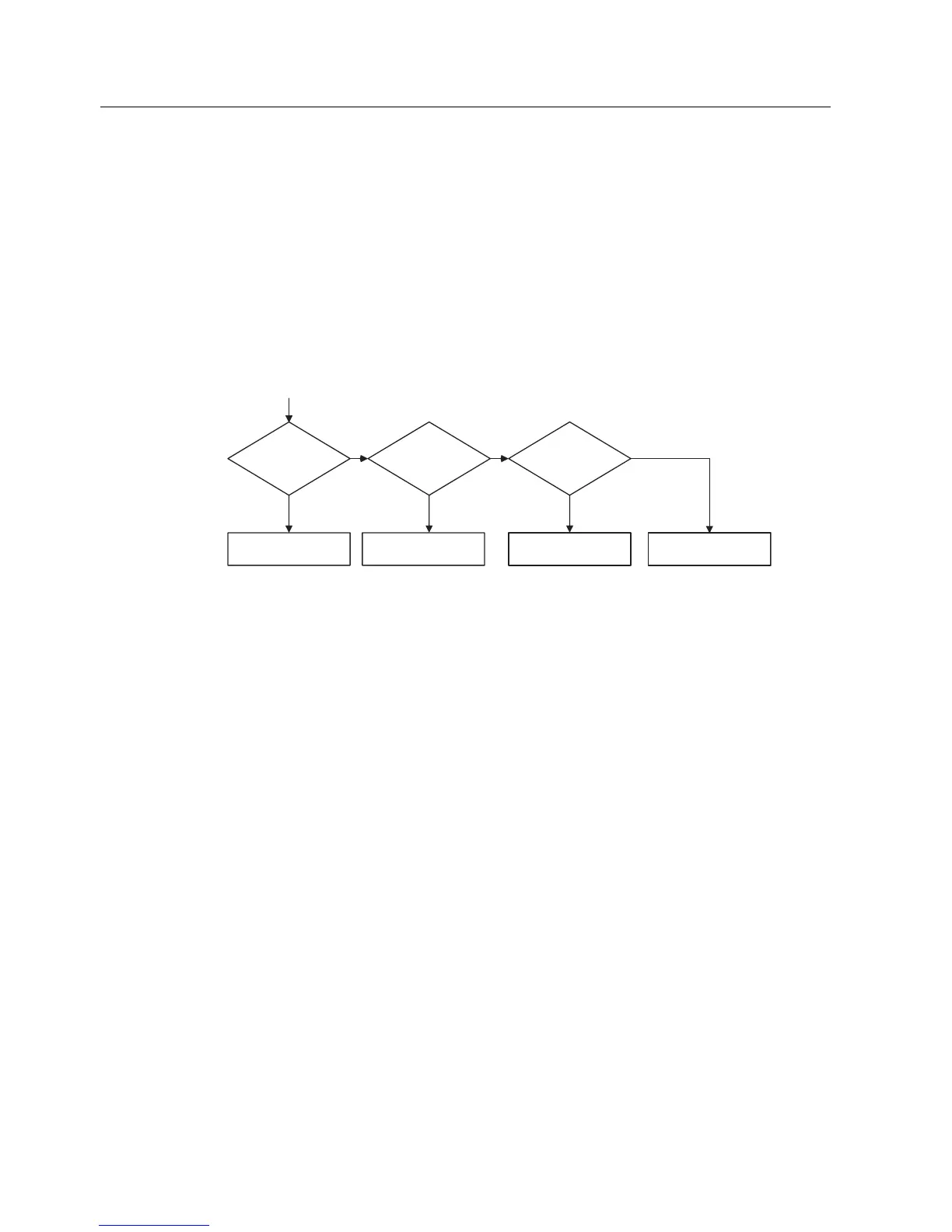

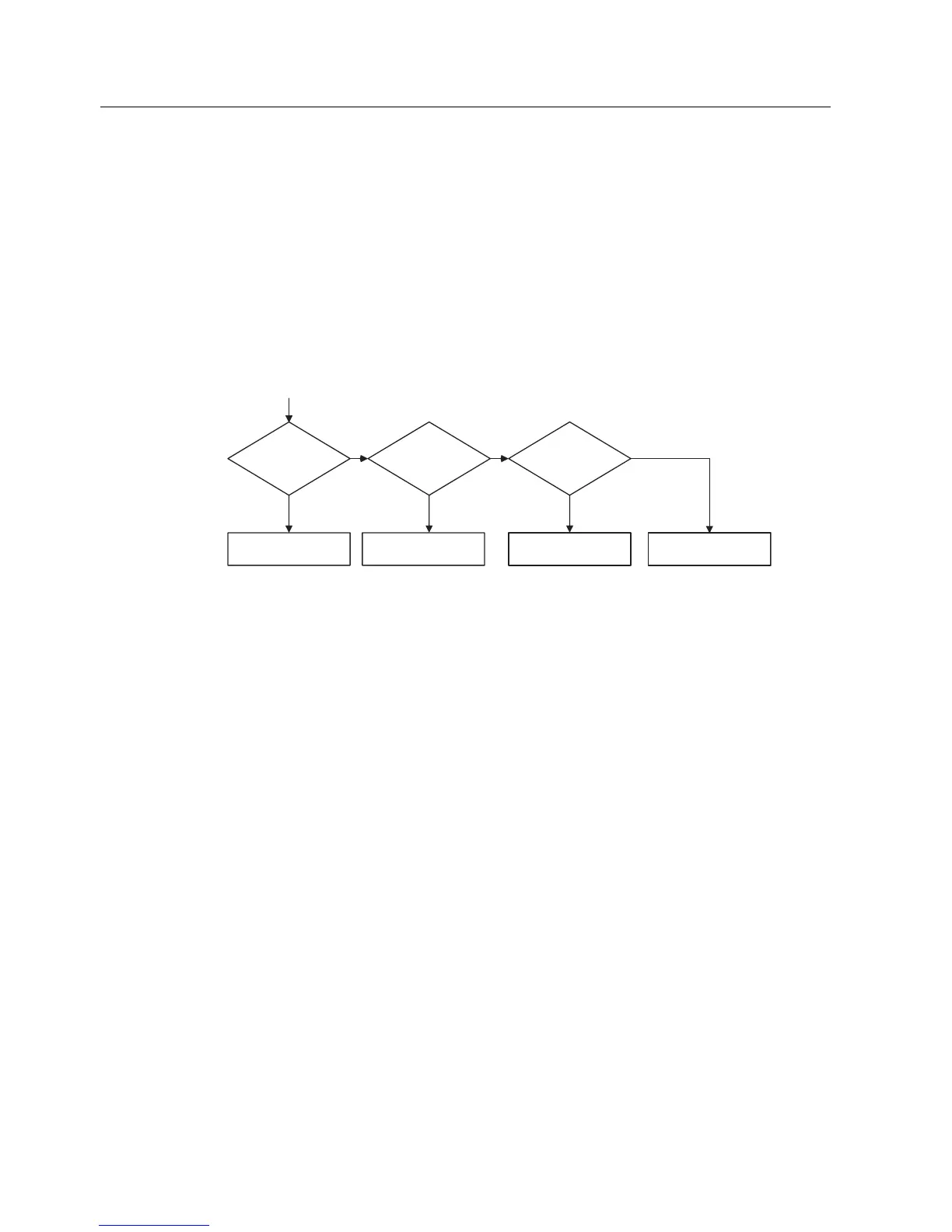

The SINAMICS G120 inverter has three electronic braking technologies:

● DC braking

● Compound braking

● Dynamic braking

These brakes can actively brake the motor and avoid a possible DC link overvoltage

condition. The figure below shows the inter-dependency of the electronic braking functions.

'&EUDNLQJ

3!

"

'&EUDNLQJ

HQDEOHG

&RPSRXQGEUDNLQJ

HQDEOHG

'\QDPLFEUDNLQJ

HQDEOHG

'LVDEOHG

&RPSRXQG

EUDNLQJ

3!

"

'\QDPLF

EUDNLQJ

3!

"

QR QR QR

\HV \HV \HV

Figure 8-56 Inter-dependency of electronic brakes

8.15.2.1 DC braking

Data

P1230, P1233

P1232, P1234

Parameter range:

r0053 Bit00

Warnings: -

Faults: -

Function chart number: -

Description

The motor decelerates along a parameterized braking ramp if an OFF1 or OFF3 command is

output. A "flat" ramp must be selected so that the inverter is not tripped (shutdown) due to

the high regenerative energy which would cause a DC link overvoltage condition. The DC

brake should be activated while the OFF1 or OFF3 command is present if the motor is to be

braked faster. For DC braking, instead of continually reducing the output frequency/voltage

during the OFF1 or OFF3 phase, from a selectable frequency, a DC voltage/current is input

(refer to sequence 1).

The motor can be brought to a standstill in the shortest time using DC current braking (DC

brake). DC braking is selected as follows:

Loading...

Loading...