Functions

8.22 Thermal motor protection and overload responses

Control Units CU240S

Operating Instructions, 11/2006, A5E00766042B AA

8-151

Features

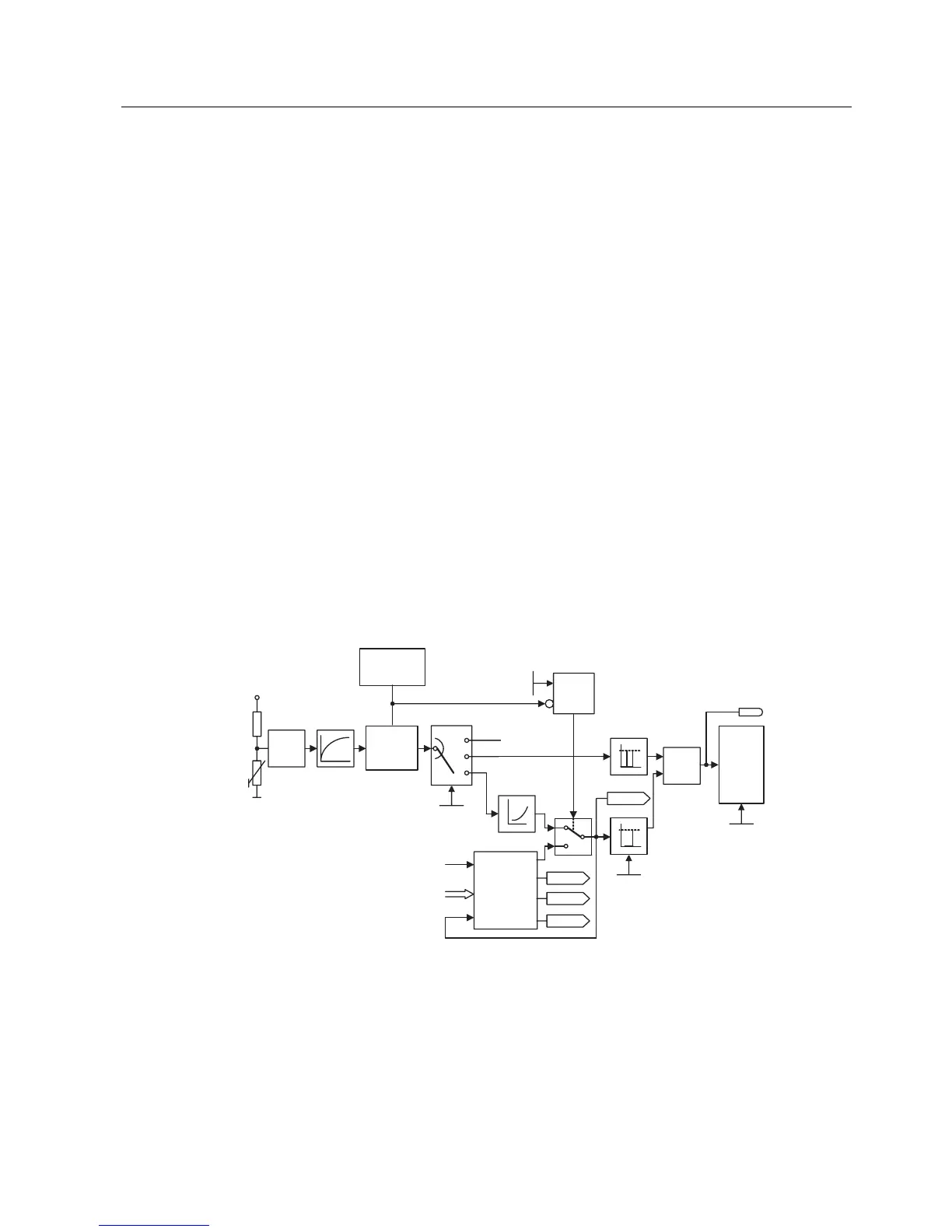

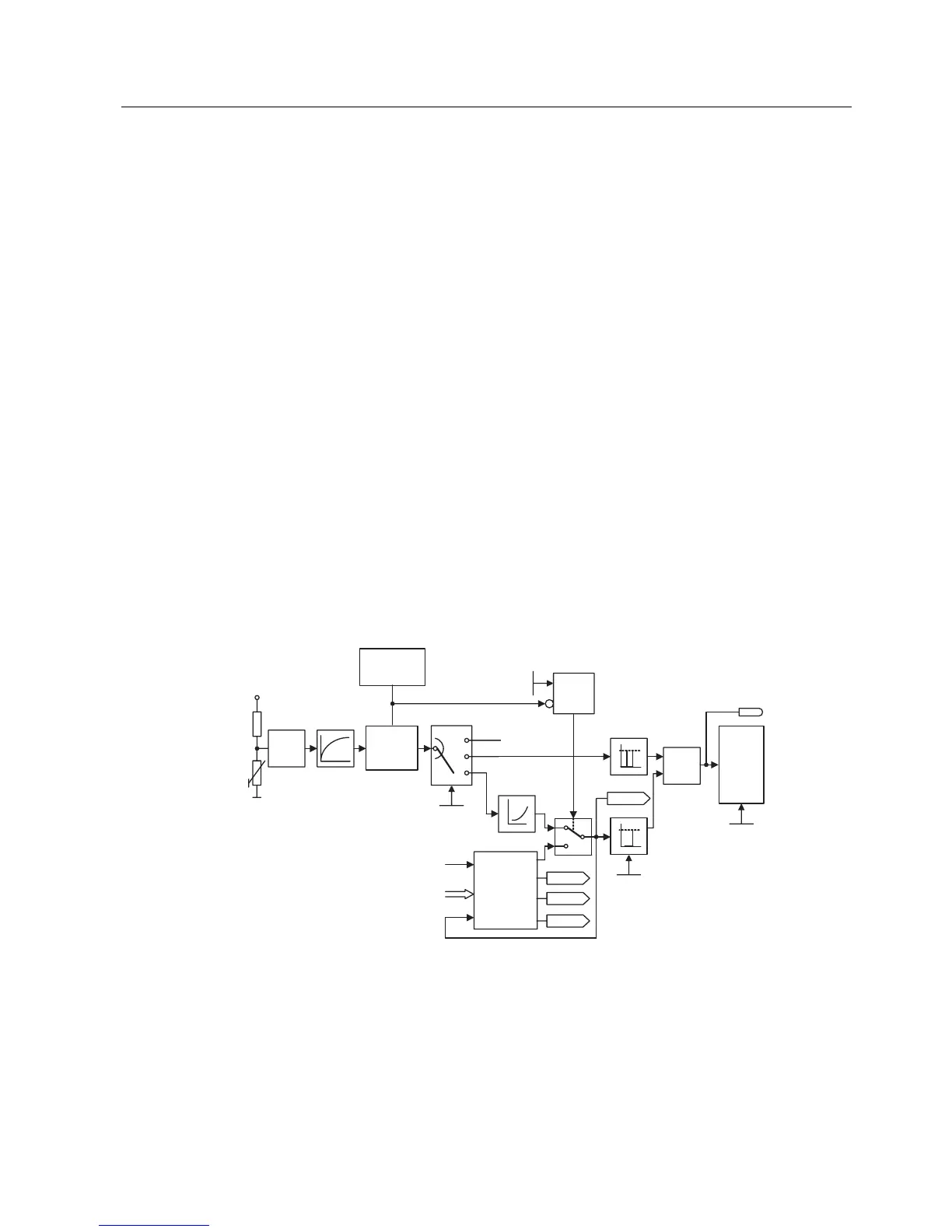

The protective concept (see figure below) distinguishes itself as a result of the following

individual features:

● Protection is effective without using any temperature sensor (P0601 = 0). The

temperatures of various locations in the motor are indirectly determined using a

temperature model.

● It is possible to evaluate temperature sensors. This has the advantage that after a line

supply failure, precise initial temperatures are immediately available. Both PTC sensors

(P0601 = 1) as well as KTY84 sensors (P0601 = 2) can be connected and evaluated.

● When using a KTY84 sensor, the inverter can be parameterized so that a sensor wire

breakage or short-circuit F0015 is detected and the system automatically changes-over to

the temperature model. This means that the inverter is not shut down (tripped) and

operation can continue.

● Selectable temperature warning thresholds P0604 (default: 130 ーC) for operation with the

temperature model or KTY84 sensor. The inverter is shut down or the current reduced

depending on P0610 for a value of P0604 +10 %.

● Selectable responses P0610 which are to be initiated when the warning threshold is

exceeded in order to prevent an overload condition.

● The motor protection has been designed to be completely independent of the inverter

protection. Warning thresholds and responses for inverter protection must be separately

parameterized.

● Various data sets are taken into account in the model. The model is separately calculated

for each data set so that when changing-over between various motors the cooling of the

presently non-active (fed) motors are taken into account.

U

%LW

U

U

U

9

7

V

37&

.7<

3

3

U

ุ

3

3

9

˽

)DXOW

)

$'&

37&

.7<

6LJQDO

ORVV

GHWHFWLRQ

(TXLYDOHQWFLUXLWGDWD

3RZHUGLVVLSDWLRQ3YPRW

7KHUPDO

PRWRU

PRGHO

1RVHQVRU

0RWRU

LW

WHPS

UHDFWLRQ

Figure 8-80 Thermal motor protection

Loading...

Loading...