Functions

8.24 Open-loop and closed-loop control

Control Units CU240S

Operating Instructions, 11/2006, A5E00766042B AA

8-181

.

3

7

Q

ಥ

ಥ

7

L

3&

3&

3&

7

L

.

3

7

Q

6/9&

9&

3

3

3

3

3

3

U

U U

U

'URRS

3UHFRQWURO

)UHTVHWSRLQW

$FWIUHTXHQF\

&,7RUTXHVHWSRLQW

%,යWRUTXHFWUO

&,$GGWUTVHWS

RQO\DFWLYHLISUHFRQWUROLVHQDEOHG3!

7RUTXH

VHSRLQW

3,

VSHHG

FRQWUROOHU

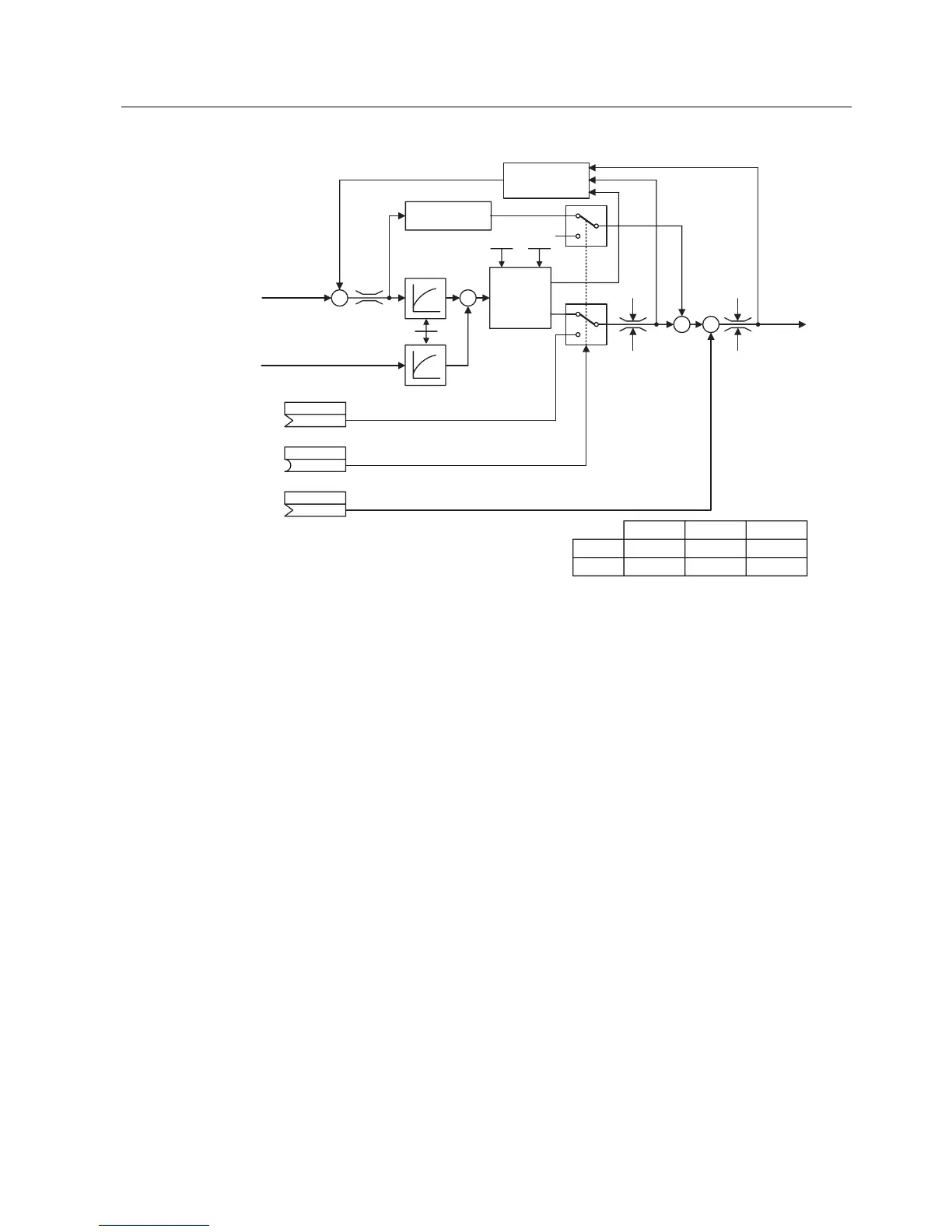

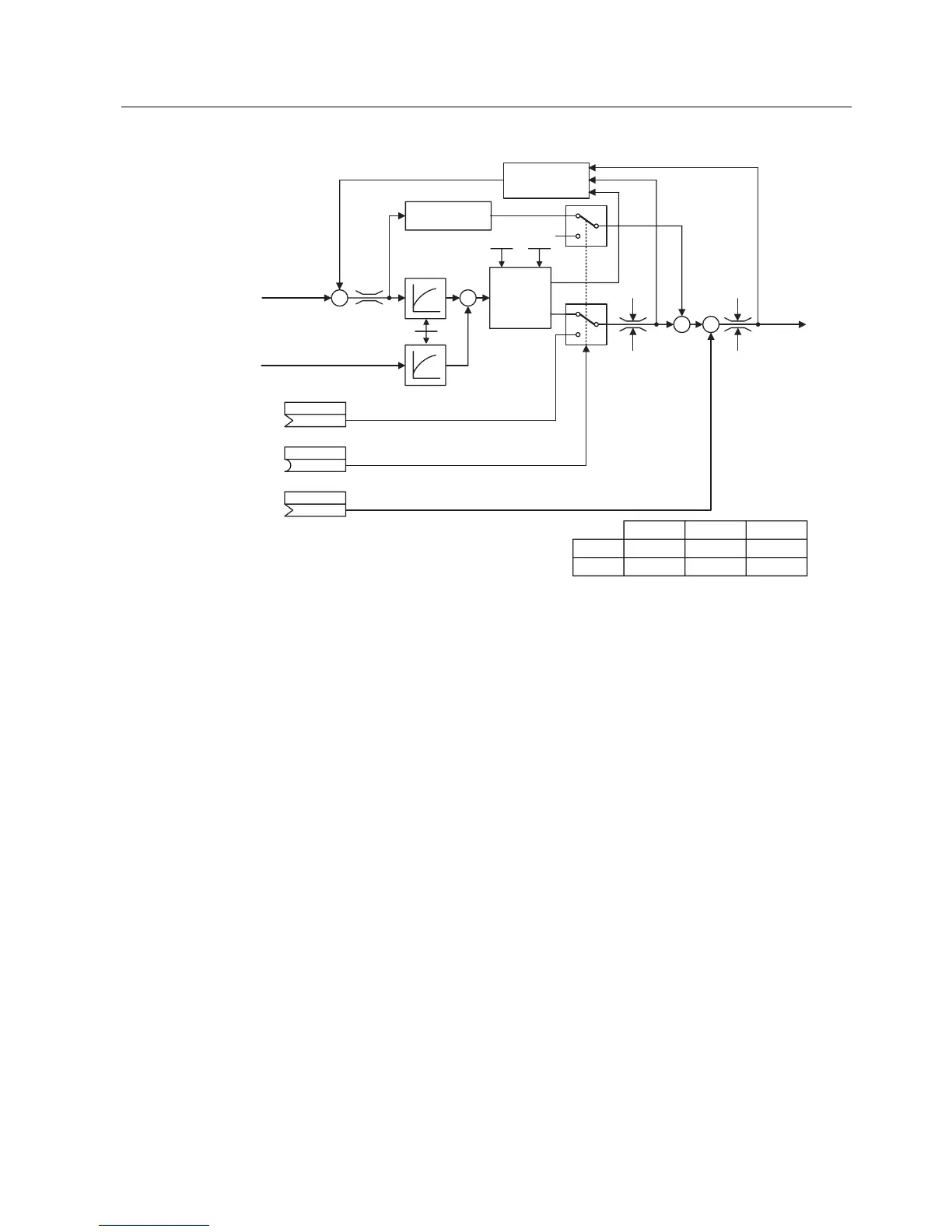

Figure 8-95 Closed-loop speed and torque control

The sum of both torque setpoints is limited in the same way as the torque setpoint of the

speed control. Above the maximum speed (plus 3%), a speed limiting controller reduces the

torque limits in order to prevent the motor accelerating any further.

A "real" closed-loop torque control (with automatically set speed) is only possible in the

closed-loop controlled range but not in the open-loop controlled range. In the open-loop

controlled range, the torque setpoint changes the setpoint speed through a ramp-up

integrator (integration time ~ P1499 * P0341 * P0342). This is the reason that sensorless

closed-loop torque control in the area around standstill (0 speed) is only suitable for

applications which require an accelerating torque and not a load torque (e.g. traversing

motors). For closed-loop torque control with sensors, this restriction does not apply.

If the closed-loop torque control is active, and a fast stop command (OFF3) is output, then

the system automatically changes-over to closed-loop speed control and braking of the

motor is started. If a normal stop command (OFF1) is output, there is no changeover.

Instead, the system waits until a higher-level control has brought the motor to a standstill, in

order to inhibit the pulses. This is necessary in order to allow the master and slave motors to

be shut down together. For P1300 = 22 or 23, for OFF1, the motor is directly powered-down

(as for OFF2).

Loading...

Loading...